How Long Does the Sterilization Cycle Usually Take When Using a Rotary Autoclave for Bird’s Nest?

In the production of ready-to-eat bird’s nest products, sterilization is one of the most crucial stages. It determines not only the product’s safety and shelf life but also its taste, texture, and nutritional value. For manufacturers seeking efficiency and consistency, the rotary autoclave has become the preferred solution. But one common question remains — how long does the sterilization cycle actually take when using a rotary autoclave for bird’s nest?

The answer depends on several factors, including product composition, packaging type, and processing temperature. However, understanding the sterilization process of a retort machine helps clarify why cycle time can vary and how manufacturers achieve optimal results without compromising quality.

1. Understanding the Rotary Sterilization Process

A rotary autoclave works by combining heat, pressure, and gentle rotation to sterilize food products in sealed containers. The rotation continuously agitates the product, ensuring even heat penetration throughout each bottle, jar, or pouch. This is especially important for high-viscosity products like instant bird’s nest, which tend to have uneven temperature distribution in static systems.

Unlike traditional static sterilizers, the rotary sterilizer achieves faster and more uniform heating, which shortens the overall process time. The rotation prevents localized overheating and helps maintain the delicate texture of bird’s nest strands — a key factor for consumer satisfaction.

2. Typical Sterilization Time for Bird’s Nest

In most cases, when using a food retort machine for bird’s nest, the sterilization cycle typically ranges from 25 to 45 minutes. This duration includes heating, holding, and cooling phases:

Heating phase (10–15 minutes): The retort machine raises the temperature to the desired sterilization point, usually between 115°C and 121°C, using high-temperature steam or hot water.

Holding phase (10–20 minutes): During this stage, the product is maintained at the target temperature to eliminate microorganisms effectively. The rotary movement ensures even distribution of heat inside the containers.

Cooling phase (5–10 minutes): Finally, the pressure and temperature are gradually reduced to protect the product’s integrity and prevent deformation of packaging materials.

The total sterilization time depends on factors such as the size of the containers, the filling volume, and whether the rotary sterilizer uses full water immersion, water spray, or steam-air mode.

retort machine

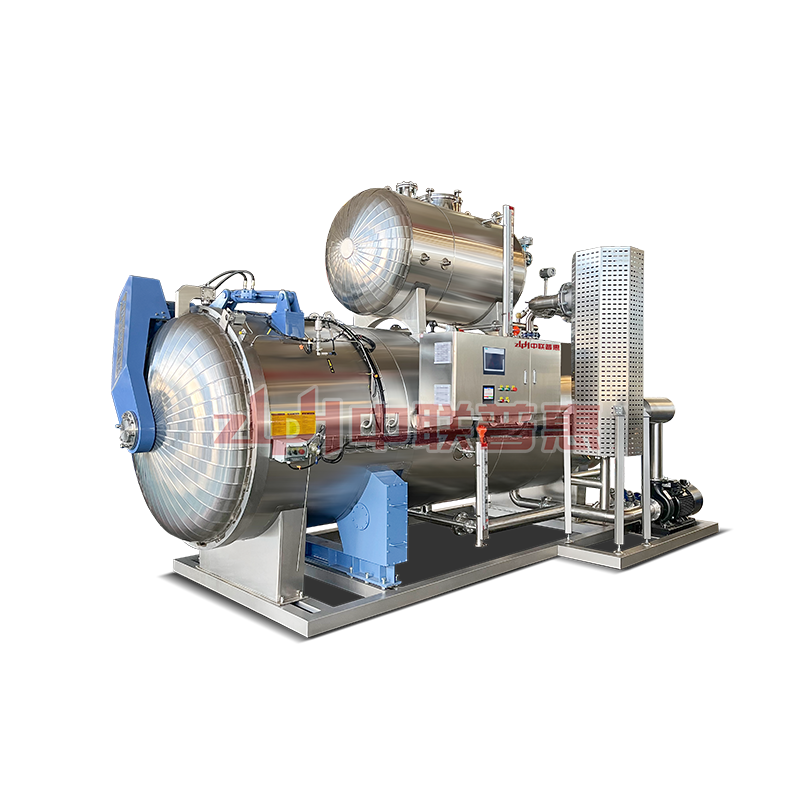

rotary autoclave

rotary sterilizer

3. Why Bird’s Nest Requires Gentle Heat Treatment?

Bird’s nest is a high-value, protein-rich food that becomes gelatinous when hydrated. Excessive heat or prolonged exposure can destroy its nutrients and cause texture loss. That’s why the retort machine are ideal for processing — they allow for precise temperature and time control.

By adjusting rotation speed, pressure, and sterilization duration, ZLPH can achieve microbiological safety while preserving the natural flavor and texture of the bird’s nest. This level of control is one of the major advantages of using a food retort machine designed for premium products.

4. Factors That Affect Cycle Duration

Several factors influence the sterilization time in a retort food machine, including:

Viscosity of the bird’s nest solution: Thicker mixtures require longer heating.

Type of packaging: Glass bottles or metal cans conduct heat differently than plastic pouches.

Batch load size: A larger load may extend heating and cooling phases.

Target sterilization value (F₀): The required lethality level varies depending on microbial safety standards.

These variables mean that even within the same rotary autoclave, cycle times may differ slightly between product batches.

When using a rotary autoclave for bird’s nest, the typical sterilization cycle lasts around 25 to 45 minutes, depending on product characteristics and processing conditions. The combination of rotation, precise temperature control, and efficient heat transfer in the retort machine ensures consistent quality, safety, and flavor. For high-value, protein-rich foods like bird’s nest, the food retort machine offers the most reliable and gentle sterilization method available in modern food processing.

retort food machine

food retort machine

retort machine