Q: What are the key sterilization challenges in sardine canning?

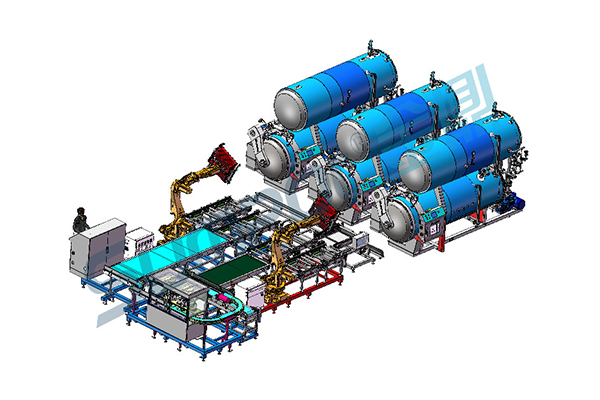

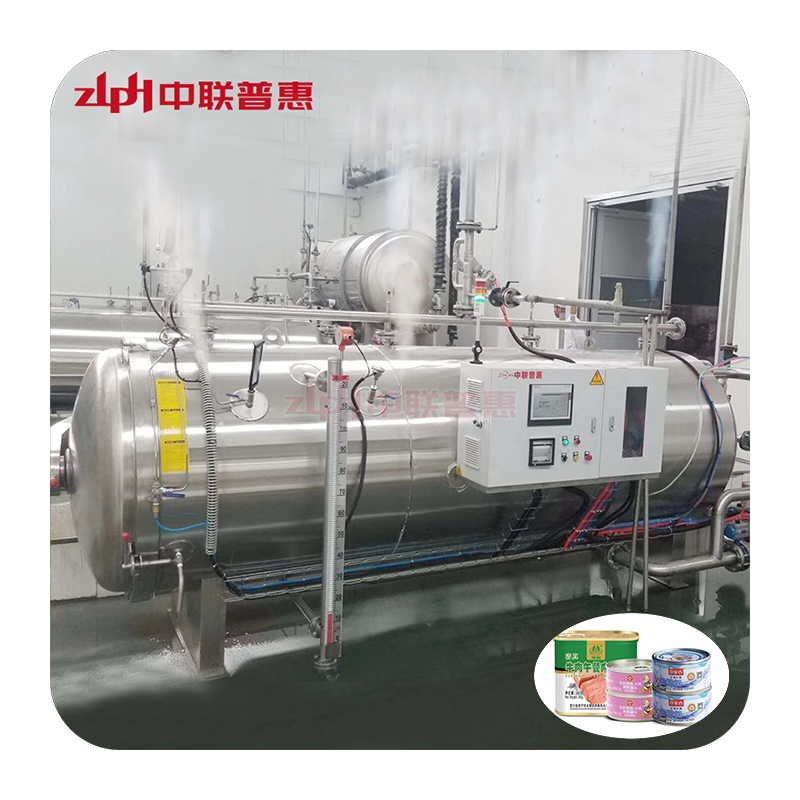

A: Sardines present unique processing difficulties due to their delicate flesh structure, natural oil content, and susceptibility to overcooking. Traditional methods often compromise texture while struggling to ensure uniform heat penetration in oil-based packing media. ZLPH MACHINERY addresses this through precision-controlled autoclave retort sterilizer systems that maintain exact temperature-pressure balance, preserving fish integrity while achieving commercial sterility.

2026-01-15

More