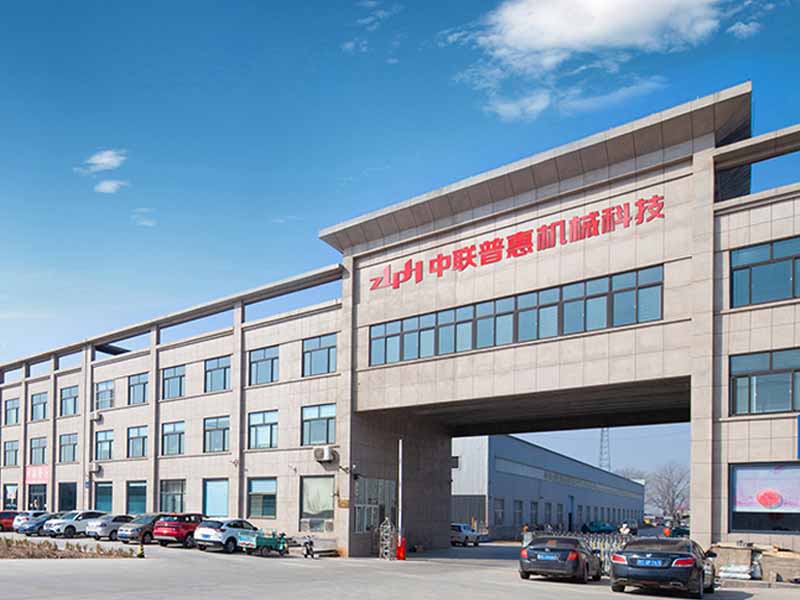

ZLPH has been breaking the barriers of food technology for a long time. Through our unparalleled persistence and high standards of product quality, we have provided high-level, advanced technology and reliable solutions to all our industry partners, which has also indirectly consolidated This reinforces our position as a leader in the food machinery industry and a trustworthy supplier.

But we don't just produce the most advanced products, long-term and mutually beneficial business relationships with our customers are our preferred philosophy, and we provide our customers with lasting service support. Our success depends on your success, and as a member of the ZLPH family, you will have a trustworthy and enthusiastic partner.

More