A leading Vietnamese bird's nest processing company, specializing in the production of high-grade edible bird's nest products for both domestic and international markets, particularly targeting the stringent requirements of the Chinese market.

The client faced significant challenges in scaling their production of ready-to-eat (RTE) bottled bird's nest and retort pouch bird's nest products. Their existing thermal processing equipment was inconsistent, leading to potential risks in microbial safety (particularly in achieving commercial sterility for Clostridium botulinum), uneven heat distribution affecting product quality, and high energy consumption. They needed a retort autoclave solution that guaranteed compliance with international food safety standards (e.g., US FDA, China's GACC), preserved the delicate texture and nutritional value of bird's nest, and improved overall production line efficiency.

Solution:

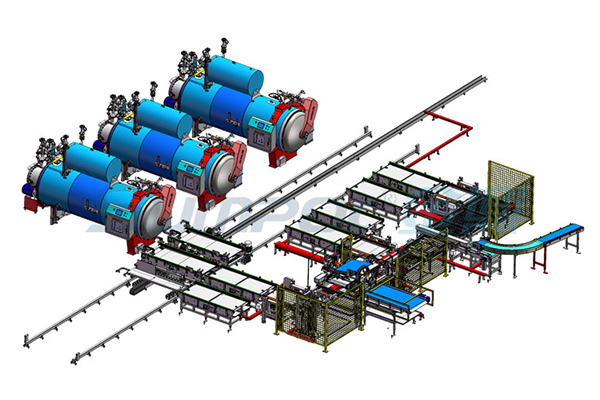

After a comprehensive technical evaluation, ZLPH MACHINERY proposed a customized, fully automated water spray retort machine system. Our solution was specifically engineered for the unique properties of bird's nest products:

Precision-Controlled Sterilization: We installed a multi-cycle food retort machine featuring our proprietary "Soft-Touch" sterilization logic. This system provides exceptionally precise control over temperature (up to 140°C) and pressure, ensuring Bird's Nest Sterilization is both thorough and gentle, eliminating harmful pathogens while maximizing the retention of sialic acid and other vital nutrients.

Uniform Process Assurance: The advanced 3D rotational water spray system within our retort autoclave guarantees uniform heat penetration to every single bottle or pouch, eliminating cold spots and ensuring 100% batch-to-batch consistency and safety.

Turnkey Integration & Support: The ZLPH MACHINERY project team provided end-to-end service, from factory layout planning and installation to comprehensive operator training and HACCP protocol assistance. We integrated the new retort food machine seamlessly into their existing cleaning and filling lines.

Results & Client Recognition:

The implementation of the ZLPH MACHINERY retort machine delivered transformative outcomes:

Quality & Safety Certification: The client successfully passed several audits by overseas import regulators, with the sterilization process data from our food retort machine being a key factor in their certification. Their Bird's Nest Sterilization protocol is now a benchmark for quality.

Operational Excellence: Energy consumption was reduced by an estimated 25% due to the efficient heat recovery system of our retort autoclave. Production capacity increased by 40% with enhanced automation.

Product Superiority: The sensory quality of their RTE bird's nest—its appearance, texture, and taste—was notably improved, giving them a competitive edge in the premium market segment.

Client Endorsement:

"The technical expertise and relentless support from the ZLPH MACHINERY team were instrumental in our success. Their deep understanding of Bird's Nest Sterilization challenges and their robust, reliable retort food machine technology have made them a trusted strategic partner. We have not only purchased a machine but also gained a long-term technology ally for our growth. We highly recommend their retort autoclave solutions to any serious food processor aiming for the highest standards."

This partnership underscores ZLPH MACHINERY's commitment to delivering not just equipment, but complete retort machine solutions that drive our clients' success in the demanding global food industry

Bird's Nest Sterilization

retort food machine

retort machine