A prominent Malaysian bird's nest processing facility has implemented revolutionary low-temperature sterilization technology, successfully preserving over 95% of sialic acid content while achieving commercial sterility standards. This breakthrough demonstrates how innovative approaches to Bird's Nest Sterilization can maintain the nutritional integrity of premium products while ensuring complete safety compliance.

Technological Innovation

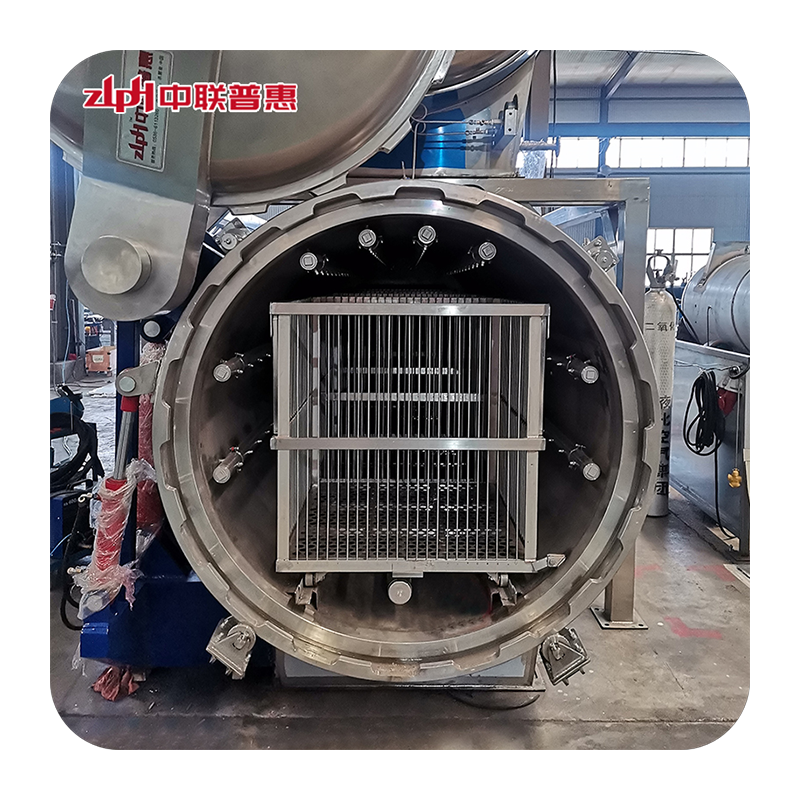

The factory adopted an advanced integrated system that combines precise temperature control with optimized pressure management. This sophisticated approach to retort sterilisation represents a significant departure from conventional high-temperature methods that typically compromise bioactive compound preservation. The customized steam retort machine configuration operates at significantly lower temperatures while maintaining effective microbial reduction through extended processing cycles and enhanced pressure control.

Implementation Process

Working with ZLPH MACHINERY's technical team, the facility implemented a specially designed Retort Machine system featuring:

Precision temperature modulation capabilities maintaining optimal processing conditions

Enhanced monitoring systems tracking real-time product quality parameters

Adaptive control algorithms adjusting processing parameters based on continuous feedback

Validated protocols ensuring consistent Bird's Nest Sterilization outcomes across production batches

Performance Results

Laboratory analysis confirmed exceptional results:

Sialic acid retention exceeding 95%

Complete elimination of pathogenic microorganisms

Superior preservation of glycoprotein structures

Enhanced product consistency across production cycles

The advanced Retort Autoclave system achieved these outcomes through scientifically validated processing protocols that balance temperature exposure with pressure-assisted sterilization efficacy.

ZLPH MACHINERY's Technical Support

Our company provided comprehensive implementation services including:

Customized system design integrating low-temperature retort sterilisation technology

Complete process validation and optimization

Staff training on advanced equipment operation

Ongoing technical support and performance monitoring

Continuous improvement recommendations based on operational data

Industry Implications

This successful implementation demonstrates that modern sterilization technology can overcome the traditional compromise between safety and nutritional preservation. The achievement of 95%+ sialic acid retention establishes a new benchmark for premium bird's nest processing, particularly important for products targeting health-conscious consumers who value both safety and nutritional efficacy.

Technical Advantages

The technology delivers multiple benefits:

Enhanced nutritional preservation without compromising safety

Improved product consistency and quality

Reduced energy consumption compared to conventional methods

Extended shelf life through optimal processing conditions

Competitive advantage in premium market segments

Future Applications

This case provides a proven model for other premium food processors seeking to preserve bioactive compounds while meeting stringent safety requirements. The technology demonstrates particular relevance for products containing heat-sensitive nutritional components where traditional sterilization methods cause significant quality degradation.