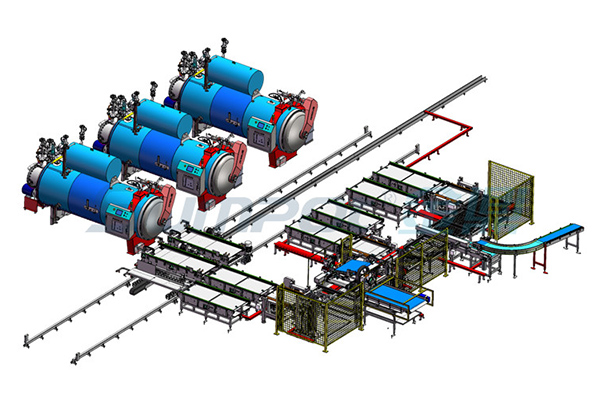

Dried Tofu Sterilization: The Advanced Retort Autoclave Solution

Vacuum bagged dried tofu is convenient and ready to eat, rich in nutrition, and favored by consumers, but its characteristics make it easy to breed microorganisms, and its shelf life at room temperature is short. The traditional sterilization method has bottlenecks in efficiency and quality protection, while the ZLPH water immersion retort machine provides a large-scale and high-quality solution. This advanced food retort machine represents a significant technological leap over conventional methods, specifically engineered to address the unique challenges of dried tofu preservation while maintaining superior product integrity.

2025-12-15

More