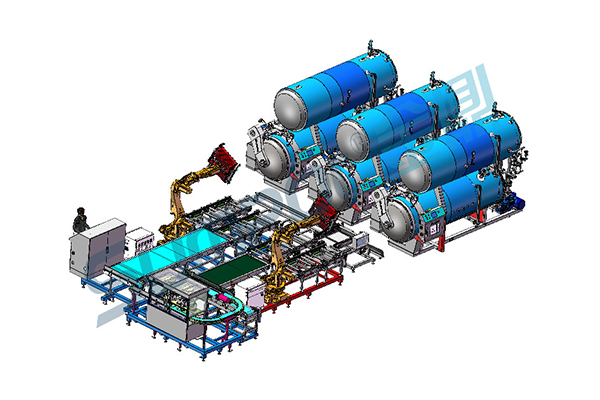

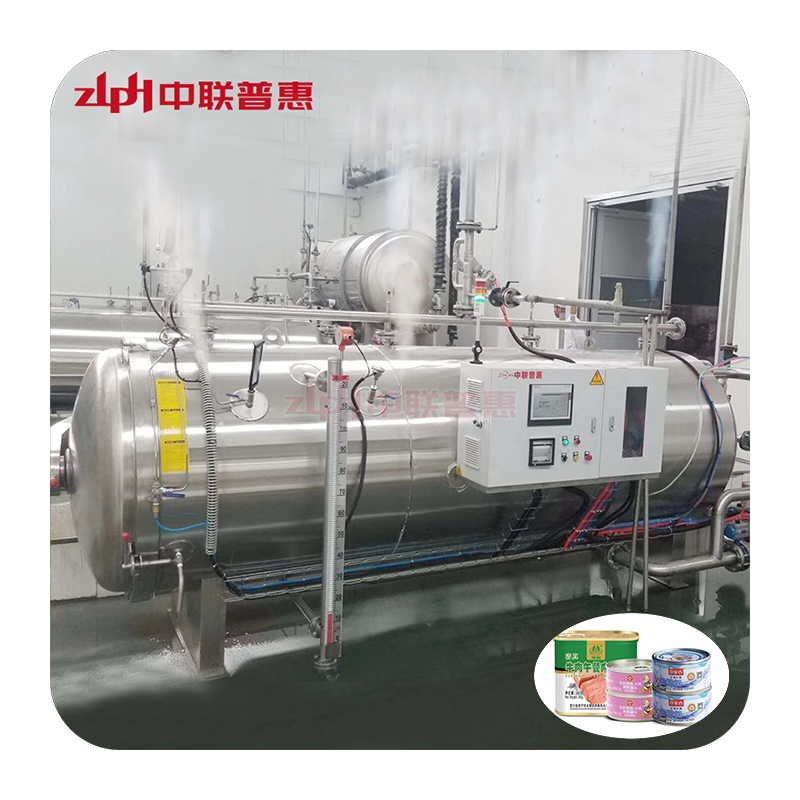

In the competitive landscape of Ready-to-Eat (RTE) meals, achieving the perfect balance of safety, quality, and scalability is paramount. ZLPH MACHINERY engineers this balance with our advanced thermal processing systems, transforming your production into a model of efficiency and reliability. Our core technology, the autoclave retort sterilizer, is not merely equipment—it is the foundation for your brand's integrity and market success.

2026-01-13

More