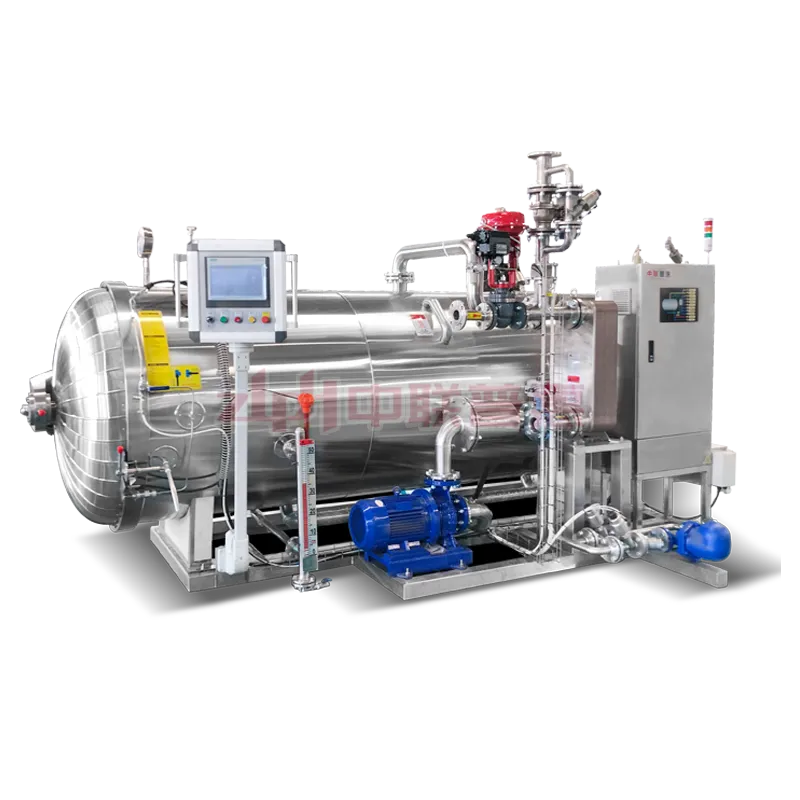

In the modern sauce manufacturing industry, the sterilization process is a critical determinant of product shelf life, sensory quality, and market acceptability. Traditional methods, such as atmospheric boiling or direct steam injection, often function as rudimentary food retort machines but lack precision, leading to the persistent trilogy of defects: burnt edges, color degradation, and package swelling. These issues severely compromise visual appeal and consumer confidence. To address these challenges, our engineering team has developed the ZLPH series—a next-generation, fully automated retort machine specifically engineered for the delicate thermal processing of viscous, particulate-laden sauces. This system transcends conventional sterilization by transforming it into a data-driven, gentle, and precisely controllable thermal art, ensuring every package meets the highest standards of safety and quality.

2025-12-24

More