FDA-Compliant Top-Spray Retort: Ensuring Superior Sterilization with Optimal Heat Distribution Our FDA-compliant top-spray retort is engineered to redefine standards in food sterilization, with every component and process aligned to meet strict FDA regulations—making it a benchmark for reliable, compliant sterilization equipment. From design to operation, the focus remains on delivering consistent heat distribution, a cornerstone of effective sterilization, while upholding FDA’s rigorous safety and performance criteria.

I. FDA-Compliant Design: The Foundation of Reliable Sterilization The top-spray retort’s design is rooted in FDA compliance, strictly adhering to 21 CFR Part 113 (Thermal Processing of Low-Acid Canned Foods) and Part 114 (Acidified Foods). This FDA-aligned framework ensures the retort excels in high-temperature, high-pressure sterilization environments, where safety and heat distribution are critical. Structurally, the retort features a cylindrical shell with an elliptical head—an FDA-compliant design validated through mechanical calculations to prevent leaks or deformation during sterilization. This robust structure supports the top-spray mechanism, which is central to achieving uniform heat distribution: a high-volume pump distributes sterilization water through a one-to-two, two-to-four, four-to-eight manifold system, directing it via top-spray nozzles to partition plates. From there, water cascades evenly over packaged products, creating a heat-transferring water film that ensures every item undergoes consistent sterilization.

Key FDA-compliant design elements enhance sterilization efficacy:

Exhaust Port: Positioned at the top to eliminate cold air pockets, a common barrier to uniform heat distribution in retorts.

Steam Controller: Equipped with precision valves to maintain ±0.2°C temperature control—vital for meeting FDA’s sterilization process requirements.

Cooling System: A large-area heat exchanger (≥2x the retort’s volume) enables indirect cooling, preventing contamination and preserving the integrity of post-sterilization products.

Linear Temperature Control: Ensures each sterilization cycle follows a predictable trajectory, with built-in ladder diagrams to document time, temperature, and pressure—critical for FDA audit trails.

F0 Calculation & Correction: Automatically adjusts sterilization intensity to meet FDA-required lethality levels, eliminating manual errors in ensuring adequate sterilization.

II. FDA-Approved Components: Precision Tools for Sterilization Control Every component of the top-spray retort is selected to reinforce FDA compliance, directly contributing to accurate sterilization monitoring and consistent heat distribution.

Pressure Gauge: A FDA-compliant gauge (≥100mm dial, 0.01MPa precision) tracks pressure fluctuations, a key variable in maintaining stable sterilization conditions.

Data Recorder: Logs sterilization data every 5 seconds in an immutable binary format, providing an FDA-ready audit trail that confirms heat distribution uniformity.

Thermometer & A1-Grade Sensor: The thermometer (80°C-135°C range, 0.5°C readability) and sensor (±0.05°C accuracy) work in tandem to monitor heat distribution, ensuring every sterilization zone meets FDA temperature standards.

304 Stainless Steel Filter Screen: FDA-approved for food contact, it prevents debris from disrupting the top-spray flow—critical for unimpeded heat distribution during sterilization.

III. FDA-Compliant Accessories: Enhancing Heat Distribution in Sterilization Accessories like baskets and layer pads are engineered to complement the top-spray retort’s sterilization capabilities. FDA mandates that layer pads have a perforated area ≥30% of total area to facilitate water flow and heat distribution. Our pads exceed this, with 15mm holes (21mm spacing) achieving a 46% perforation ratio—ensuring water penetrates all layers of packaged products for uniform sterilization.

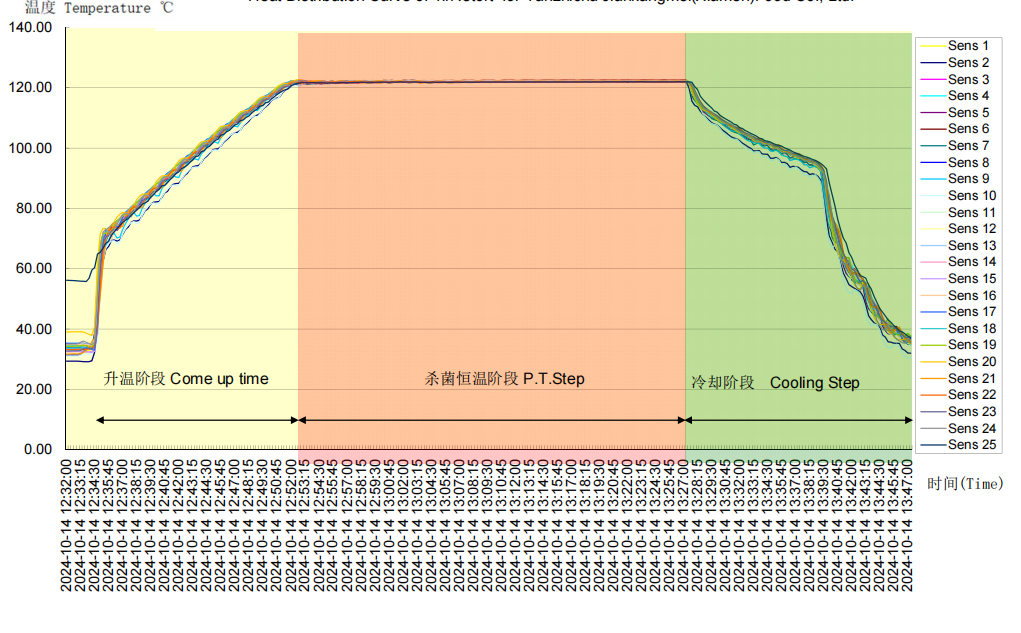

IV. Superior Heat Distribution: The Hallmark of FDA-Compliant Sterilization Heat distribution is rigorously tested per FDA standards, with multiple sensors placed throughout the retort to map temperature variations during sterilization. Results confirm temperature deviations ≤±0.3°C across all zones—proof that the top-spray design eliminates cold spots, a critical FDA requirement for effective sterilization. During heating, the top-spray system creates a controlled temperature gradient that equalizes during holding, while cooling phases reverse this gradient to maintain overall thermal balance. This symmetry ensures every product undergoes the same sterilization intensity, meeting FDA’s microbial reduction criteria.

V. Conclusion: The FDA-Compliant Top-Spray Retort—A Sterilization Leader Our top-spray retort stands as a paragon of FDA compliance, integrating design, components, and accessories to deliver exceptional sterilization performance. By prioritizing heat distribution, precision control, and FDA-aligned processes, it ensures food safety, meets regulatory demands, and provides customers with a sterilization solution they can trust. For reliable, compliant, and efficient food sterilization, the FDA-compliant top-spray retort is the definitive choice.

If you’re interested in learning more about our ZLPH Retort or exploring potential cooperation opportunities, feel free to reach out to us via email at saleshayley@zlphretort.com or connect with us on WhatsApp at +86 15315263754.