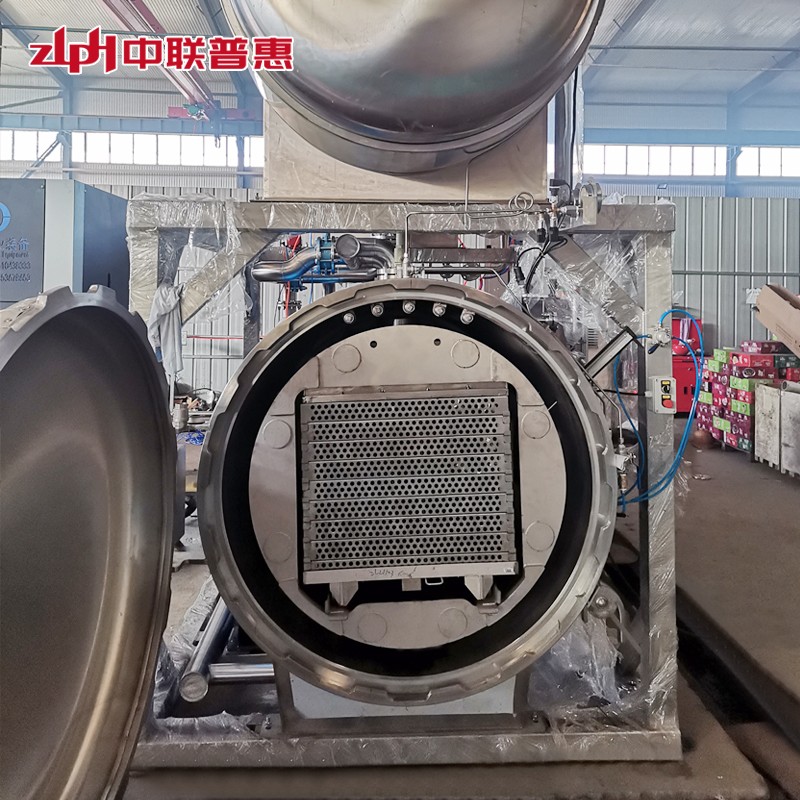

In the dynamic field of food research and development, achieving accurate, scalable, and reproducible sterilization results has long been a critical challenge. The introduction of the revolutionary laboratory retort autoclave by ZLPH marks a transformative advancement, directly addressing the core pain points in food science. This state-of-the-art retort machine is engineered to simulate industrial-scale thermal processing with unprecedented fidelity, bridging the persistent gap between benchtop experimentation and full-scale production. It provides researchers with a precise, data-driven tool for developing and optimizing processes that achieve true Commercial Sterilization.

This innovative food retort machine integrates multiple sterilization modalities—including steam, water spray, immersion, and rotary agitation—within a single compact unit. Equipped with a high-efficiency heat exchanger, it can accurately replicate the exact conditions of industrial retort autoclave systems. This capability is vital for ensuring that laboratory results directly translate to manufacturing success, eliminating costly scaling errors and reducing time-to-market for new products. The system’s rotation mechanism, combined with high-pressure steam and precisely controlled spray or immersion cycles, guarantees uniform heat distribution. This ensures every sample, regardless of its position or viscosity, receives consistent thermal treatment, which is fundamental for validating both food safety protocols and product quality parameters such as texture, color, and nutrient retention.

A cornerstone of this advanced retort machine is its integrated real-time F0 value monitoring system. This technology tracks microbial lethality continuously throughout the sterilization cycle, providing objective, quantitative data on the achievement of Commercial Sterilization. All process data is synchronized to a centralized digital monitoring platform, offering researchers complete traceability, from initial parameters to final microbial reduction logs. This data-driven approach replaces estimation with empirical evidence, empowering R&D teams to make informed decisions.

For food scientists and product developers, the versatility of this laboratory food retort machine is a game-changer. It offers fully customizable parameters for temperature, pressure, cycle time, and agitation speed. This flexibility allows for the meticulous optimization of sterilization recipes tailored to specific product categories—whether testing the thermal resistance of a new low-acid formulation in a flexible pouch or perfecting the process for a high-value ready-to-eat meal in a glass jar. By enabling precise small-batch testing that reliably predicts industrial retort autoclave performance, the system significantly reduces product loss during scale-up, accelerates development cycles, and ensures regulatory compliance from the earliest stages.

ZLPH operates under the core philosophy of "Precise Empowerment of Innovation, Technology Guarding Food Safety." This laboratory retort machine embodies that commitment. It is more than a piece of laboratory equipment; it is a foundational tool for innovation. By providing reliable, accurate, and scalable Commercial Sterilization data, ZLPH empowers global food companies to develop safer, higher-quality, and more sustainable products. This technology supports the entire R&D ecosystem, from academic institutions and ingredient suppliers to multinational food brands, in navigating the complex journey from concept to consumer with confidence and scientific rigor.

In an industry where safety and quality are non-negotiable, investing in R&D tools that offer precision and predictive accuracy is paramount. The ZLPH laboratory retort autoclave stands as a critical asset for any team dedicated to advancing food science, ensuring that the path to Commercial Sterilization is not a hurdle, but a precisely mapped route to success and market leadership.