How to automate production in tin cans?

The automation of tin can production is an important step in the development of modern food industry. This not only simplifies the process but also significantly enhances the efficiency and quality of the products. So far, technology has reached such a level that with the help of modern automated systems, almost every production stage can be improved. This article discusses the main aspects of the process automation, from design to finished product packaging. Special attention is paid to the automatic production line for sterilized food in tin cans, which can provide high performance and quality at every stage.

Automated design and planning

To successfully achieve the automation of tin can production, it is necessary to start with careful design and planning. This process involves an analysis of current production capacity, an assessment of the possibility of integrating new technologies, and the formulation of an action plan. First of all, it is important to review the existing processes to identify the key areas for modernization. For instance, the production speed of a tin can can be estimated and the production bottlenecks that slow down the entire process can be identified.

After analysis, it is necessary to consider the possibility of integrating the automatic production line into tin cans for the production of disinfected food. Such a system can significantly enhance productivity by automating the sterilization and packaging processes. It is important to take into account that successful automation not only requires the use of the latest technology but also the training of personnel to use new systems. Employee training is a crucial stage. Without training, the expected results cannot be achieved.

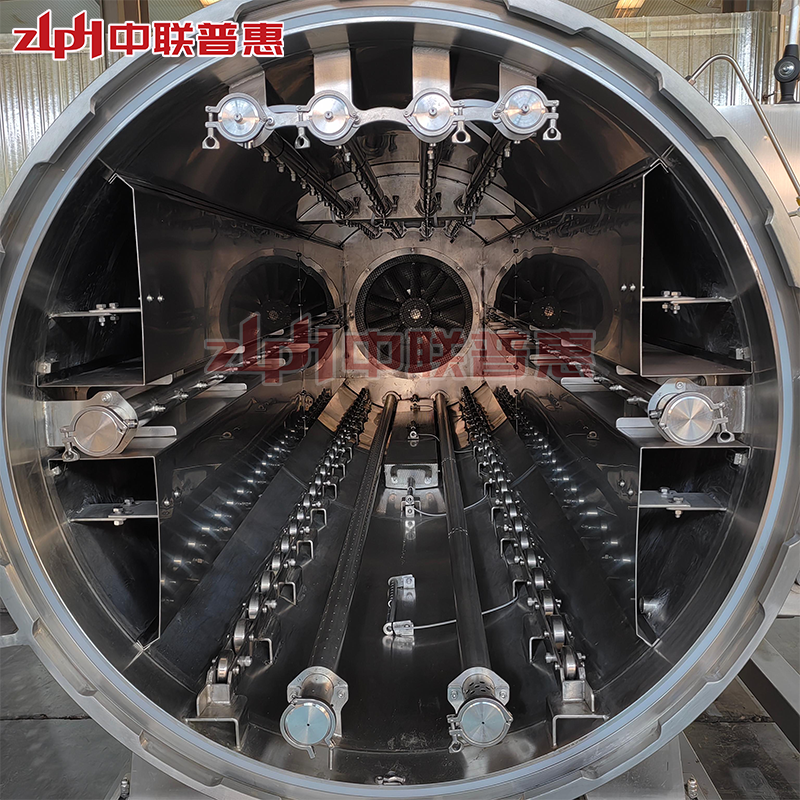

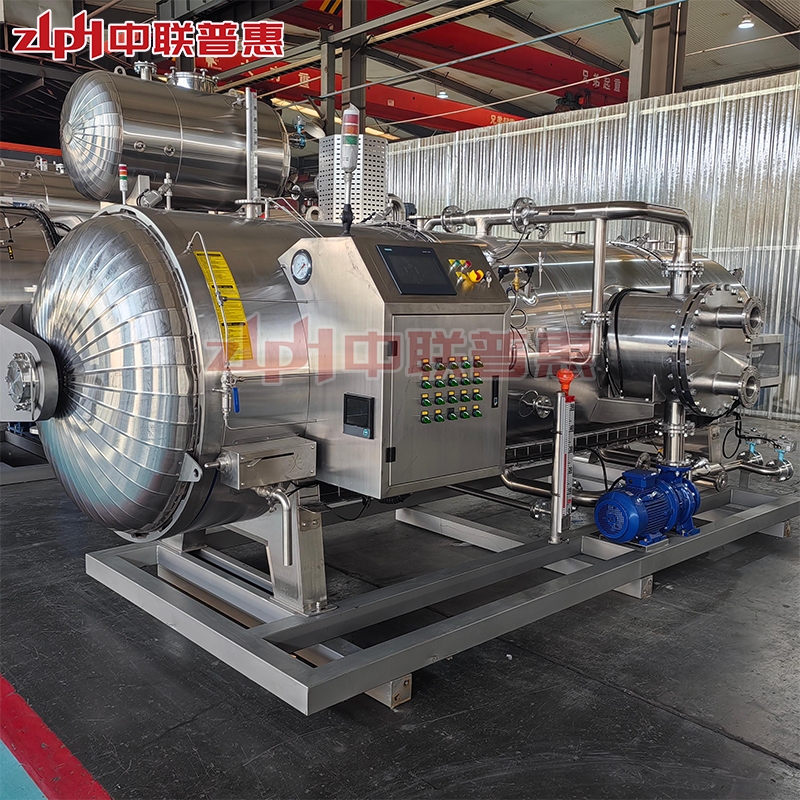

Selection and installation of equipment

One of the most crucial stages is to select and install the appropriate equipment. The modern automatic production line for tin can sterilized food is equipped with the most advanced equipment, including retort, packaging machines and transportation systems. When choosing equipment, factors such as production speed, compatibility with existing systems, and the possibility of expanding the production line in the future should be taken into consideration.

Equipment installation requires caution, as the slightest mistake at this stage may have serious consequences for the entire production process. Therefore, it is best to involve experts with such working experience. It is also important to test the installed system to ensure everything is working properly and to identify any potential problems at an early stage.

Integrate with the existing system

After the selection and installation of the equipment, the new automatic production line is integrated with the existing system into the tin cans to produce disinfected food. This not only includes physical integration but also the configuration of production process management software. It is of great significance that all systems are interconnected and can exchange data in real time.

System integration can be an important task, especially if an enterprise uses outdated equipment. In this case, additional efforts may be needed to adapt the new equipment to the old system. However, when the company starts working, all these efforts will pay off without delay and with the highest efficiency.

Employee training and work monitoring

The automation of the production process is impossible without the participation of qualified personnel. Training employees to use new equipment and software is a mandatory stage. At this stage, employees must master the basic principles of the automation system and learn how to maintain it and troubleshoot possible problems.

It is very important to install a system for monitoring the operation of new lines while conducting training. The data obtained with the help of such a system enables you to control productivity, identify possible faults, and respond quickly to any situation that deviates from normal operation. This greatly enhances the reliability of the entire production system and helps improve product quality.

Maintenance and modernization

Without regular maintenance, the automatic production line for sterilized food in tin cans cannot operate. This includes scheduled checks and prompt fault diagnoses that may occur during operation. Regular maintenance can extend the service life of equipment and keep it in the best condition.

Modernization also plays a significant role in maintaining the competitiveness of enterprises. New technologies are constantly evolving. Timely introduction of them into production can enhance product quality and reduce costs. For instance, the introduction of new software solutions for managing production processes can significantly simplify the work of operators and improve process coordination.

The advantages of automation and future development

The automation of tin can production brings many benefits, including increased productivity, improved product quality and reduced costs. The automatic production line for sterilized food in tin cans ensures the reliable and efficient operation of enterprises, enabling them to remain competitive in the market.

The future development of automation is related to the integration of artificial intelligence and machine learning, which can lead to the creation of self-adjusting production systems. Such technologies will further enhance production, making it flexible and adaptable to the constantly changing market conditions. The introduction of innovative solutions based on artificial intelligence also helps to enhance occupational safety levels, which is an important factor for modern enterprises.

If you’re interested in learning more about our ZLPH Retort or exploring potential cooperation opportunities, feel free to reach out to us via email at saleshayley@zlphretort.com or connect with us on WhatsApp at +86 15315263754.