Innovation in Retort Technology: Fortifying Safety and Quality Foundations for the Pet Food Industry

Amid the vigorous development of the pet food industry, pet owners are paying increasing attention to food safety and quality—making the sterilization process a key determinant of a product’s market competitiveness. As core equipment for safeguarding pet food safety, retorts are undergoing comprehensive technological innovations, injecting new momentum into the industry’s growth.

Precise Temperature Control for Effective Sterilization

Traditional retorts often suffer from uneven temperature distribution, leading to incomplete sterilization of some pet food products, residual harmful microorganisms, and potential risks to pet health. Today, advanced retorts are equipped with cutting-edge intelligent temperature control systems, enabling precise regulation of temperature fluctuations within an extremely narrow range. For instance, high-end retorts can achieve a temperature control accuracy of ±0.3℃, ensuring every corner of the food inside the retort is sterilized at an optimal temperature. When processing pet food cans, precise temperature control maintains a stable sterilization temperature of 121℃—a temperature that effectively eliminates common pathogenic bacteria such as Salmonella and Listeria, significantly enhancing product safety. According to relevant test data, the microbial non-compliance rate of pet food has dropped by over 70% after adopting such advanced retorts, laying a solid foundation for pets’ healthy diets. Notably, due to their unique drying process, dry pet food already achieves a certain level of sterilization through high-temperature drying during production and generally does not require additional retort treatment. However, it is crucial to maintain dry conditions during subsequent storage and transportation to prevent microbial growth.

Innovative Sterilization Methods: Balancing Nutrition and Palatability

Preserving nutrition and ensuring palatability are critical for pet food. Traditional sterilization methods often destroy large amounts of nutrients and compromise taste while eliminating bacteria. To address this issue, retorts now adopt spray sterilization technology: high-temperature hot water is evenly sprayed onto the food surface via top or side spray devices, enabling rapid and uniform heating for sterilization. This method shortens the food’s exposure to heat, minimizing nutrient loss of vitamins, proteins, and other essential components. Take wet pet food as an example—after treatment with spray retorts, the retention rate of vitamin C can reach over 85%, and the food’s color, texture, and flavor remain closer to the original state of the ingredients. In pet palatability tests, pet food processed with this innovative sterilization method was 25% more preferred by pets compared to products treated with traditional sterilization, effectively boosting market competitiveness.

Enhanced Production Efficiency and Reduced Energy Costs

Against the backdrop of intensifying market competition, pet food manufacturers have an urgent need to improve production efficiency and control costs. Advanced retorts feature optimized designs that significantly reduce heating and cooling times, enhancing production efficiency. Some retorts are equipped with high-efficiency steam generation systems and rapid exhaust devices, shortening the production cycle of each batch by 20% to 30%. Meanwhile, in terms of energy conservation, advanced retorts adopt cutting-edge thermal insulation materials and heat recovery technologies to significantly reduce energy consumption. Heat recovery systems recycle waste heat generated during sterilization for preheating the next batch of products or supplying other production processes. A medium-sized pet food manufacturer reported a monthly energy cost reduction of 120,000 yuan after adopting advanced retorts. Lower production costs provide greater flexibility in pricing and strengthen market competitiveness.

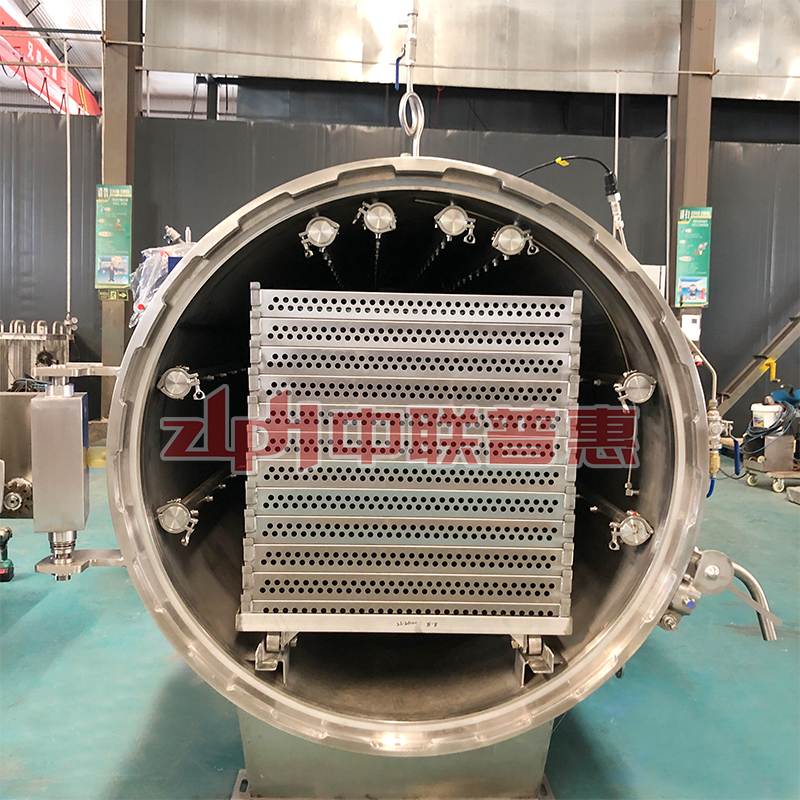

Customized Designs for Diverse Production Needs

Considering the varied scales of pet food manufacturers and the wide range of product types, ZLPH offers customized services. For small-scale enterprises with low output and flexible product lines, compact retorts with user-friendly operations are designed to meet their needs for small-batch, multi-variety production. Large-scale manufacturers can opt for high-automation, continuous-operation retort equipment. For different types of pet food—such as canned pet food, wet food, and functional pet food—retorts can be customized with exclusive sterilization protocols based on product characteristics. For example, for meat-rich pet food, sterilization temperature and duration are adjusted to ensure thorough sterilization without compromising taste; for pet food containing heat-sensitive ingredients like probiotics, low-temperature short-time sterilization is adopted to ensure sterilization effectiveness while maximizing probiotic activity.

As the pet food industry continues to develop, consumer demands for product safety and quality will keep rising. With distinct advantages such as precise temperature control, innovative sterilization methods, energy efficiency, and customized designs, advanced retorts are becoming a powerful tool for pet food manufacturers to improve product quality and enhance market competitiveness—driving the entire industry toward a safer, more nutritious, and more efficient future.