The customized retort autoclave produced by our company innovatively adopts an advanced linear temperature rise control system. This design not only fully complies with the strict regulatory requirements of the FDA, but also achieves a breakthrough improvement in control accuracy and can accurately control the temperature. Within the tiny range of ±0.3°C. This high-precision temperature control is an important cornerstone to ensure safety and quality during food processing.

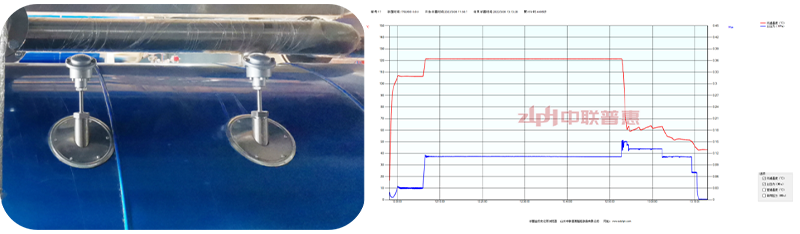

It is particularly worth mentioning that the retort implements a redundant dual-branch design in terms of key sensing systems, namely temperature and pressure monitoring. This design uses dual sensors to work in parallel and back up each other, effectively reducing the risk caused by a single sensor failure and further improving the stability and reliability of the sterilization process.

We supplied the high quality retort autoclaves are equipped with a new intelligent temperature control system that demonstrates excellent performance when sterilizing perishable, temperature-sensitive dairy products. It can significantly reduce the loss of nutrients and degradation of product quality caused by temperature fluctuations. Compared with traditional retort, the retention rate of nutrients has been improved by up to 15%. This achievement not only provides strong technical support for food companies and helps them improve their product market competitiveness, but also deeply reflects the vital role of precise temperature control in ensuring food quality and safety in the food processing industry. With its leading advantages in temperature control, our retort has set a new benchmark in the food processing industry.