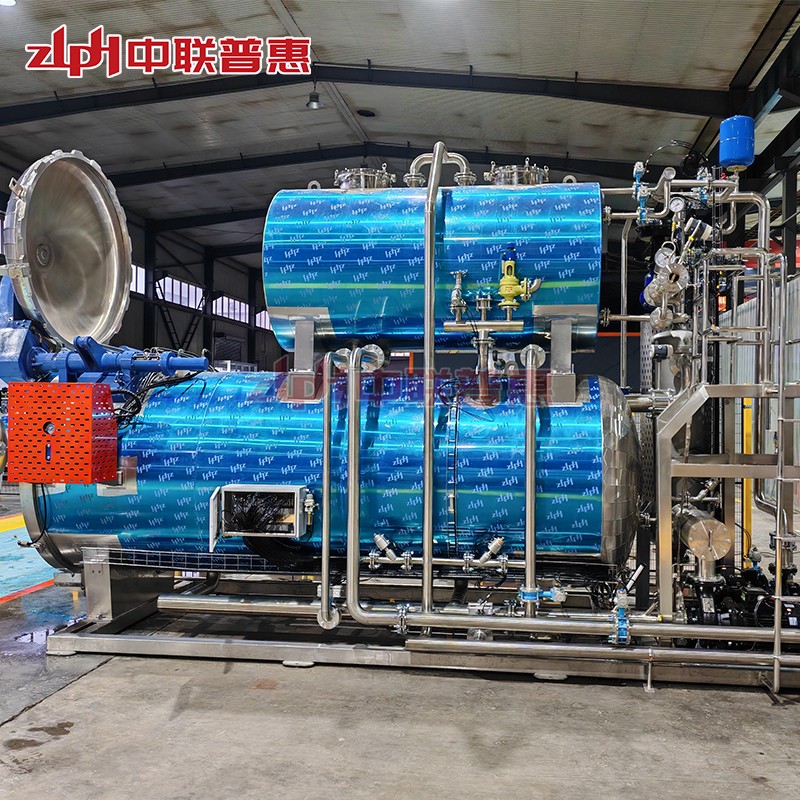

Recently, our company ZLPH successfully completed the testing of a customized retort, which will be shipped to a customer factory specializing in cat strip production. The research and development and testing of this retort are aimed at meeting customers’ strict requirements for efficient and accurate sterilization in the production process of cat strips.

During the entire testing phase, our technical team comprehensively monitored and optimized the key performance indicators of the retort. By simulating the production process of cat strips of different batches and specifications, the equipment is ensured to achieve the best state in terms of temperature control, pressure regulation and sterilization time accuracy. After multiple rounds of rigorous testing, the retort not only ensures the food safety standards of cat strips, but also retains the taste and nutritional content of the product to the greatest extent.

At present, the retort has successfully passed all test links, and the preparations before shipment are proceeding in an orderly manner. Our logistics team strictly follows the standard process, carefully packs the equipment, and arranges a professional transportation team to ensure that the retort is delivered to customers safely and on time, helping customers quickly start a new journey of cat strip production.

As a leading retort manufacturer in the industry, we are always committed to providing customers with customized high-quality solutions. In the future, we will continue to increase our investment in research and development, continuously improve product performance, and provide more reliable and efficient sterilization equipment for global food production companies.