There are significant differences in the sterilization processes between flexible packaging canned products and traditional metal canned products, mainly reflected in the application parameters of the retort and the process design:

Sterilization Temperature and Pressure

Due to the high temperature and pressure resistance of the materials used in traditional metal canned products, they usually adopt a high temperature above 121°C in combination with high-pressure steam (such as in a rotary retort) to ensure commercial sterility. For flexible packaging canned products, because the temperature resistance of the composite film materials is relatively low (usually ≤115°C), the sterilization temperature needs to be reduced and the time shortened to avoid packaging deformation or delamination between layers.

Optimization of the Heat Transfer Method

Metal cans have fast heat conduction but have "cold spots" (such as at the seam of the can body), and it is necessary to fully cover them through the water circulation of the retort. Flexible packaging mostly adopts vacuum skin packaging and requires the use of a water spray-type or water immersion-type retort. High-frequency vibration or ultrasonic waves are used to assist heat conduction to solve the problem of slow heat conduction of the film.

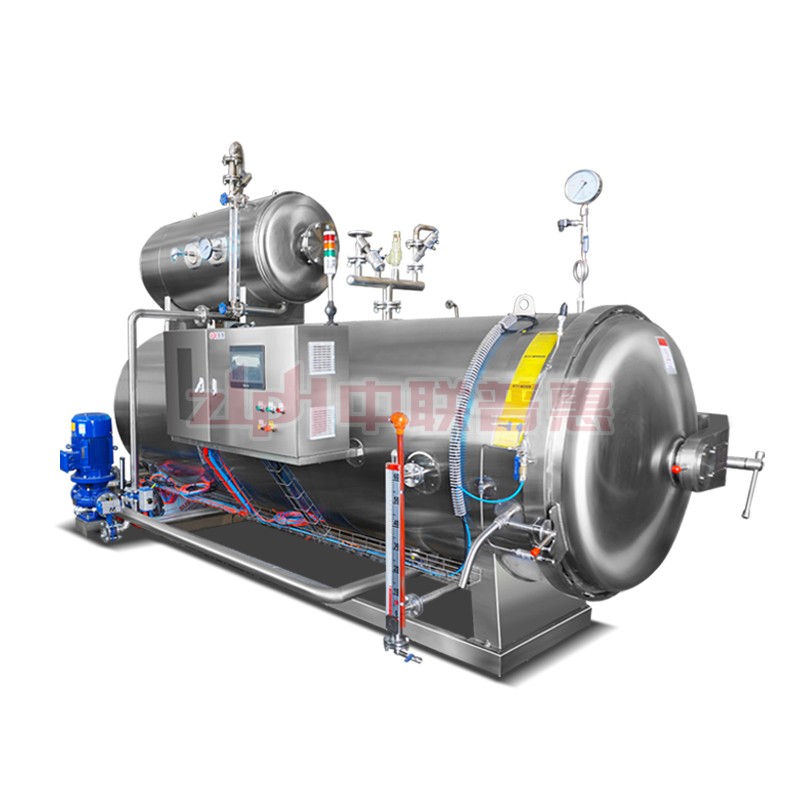

Selection of the Type of Retort

Metal canned products mostly use intermittent static retorts (such as basket-type ones), which can handle a large quantity in a single batch. Since flexible packaging is vulnerable, continuous sterilization equipment (such as a spiral mesh belt type) is required. It is equipped with precise temperature probes to achieve dynamic monitoring and avoid local overheating.

Differences in the Cooling Process

Metal canned products can be directly cooled rapidly by water spray with ice water. Flexible packaging requires staged cooling (first pre-cooling with warm water and then rapid cooling with cold water) to prevent the packaging from wrinkling or the contents from expanding due to sudden cooling. At the same time, a backpressure device is equipped to balance the internal and external pressure differences.

Differences in the Focus of Verification

The verification of the sterilization process for metal canned products takes the F value (sterilization lethality rate) as the core. Flexible packaging requires additional detection of packaging integrity (such as using the dyeing method to detect micro-holes), sealing strength, and oxygen barrier property during the storage period to ensure the reliability of the non-metallic barrier.

These differences have prompted the development of sterilization equipment towards modularization and intelligence. For example, flexible adjustment of the flexible packaging process is achieved through PLC control, or microwave-assisted sterilization is used to make up for the defects of the cold spots in metal canned products, reflecting the technological drive of different packaging forms for the sterilization process.