Technical Solution for Corn Cob Production Line and Sterilization Packaging Line

I. Detailed Process Flow of the Corn Cob Production Line

Corn Husking

The JWBT 10000 model air-blowing husker is utilized, spraying high-pressure gas from the side or bottom to separate the husk from the corn cob via airflow pressure. This process on the production line reduces damage rate by 40% compared to traditional mechanical husking, handling 10,000–12,000 cobs per hour with a stainless steel body ensuring food hygiene.

Trimming (Cutting Head and Tail)

The FYHZ 4000 model trimming machine on the corn cob production line uses high-speed rotating blades for precise cutting per set lengths, with ±1mm error control. Trimmings are recycled for feed, and the equipment links with the assembly line, adapting to large-scale fresh corn cob processing with 2,000 continuous fault-free hours.

Washing and Blanching

The ZYD 8000 model washing and blanching machine employs low-pressure nozzles and bubble tumbling on the production line for all-around impurity flushing. Blanching temperature (85–95℃) and time (3–5 minutes) are precisely adjustable to inactivate enzymes, prevent browning, and kill surface microorganisms.

Cooling and Drying

The ZYD LD-5000 model cooling water tank sprays 5–10℃ circulating cold water, reducing corn cob temperature to room temperature within 30 seconds on the production line. After draining, the cobs enter the ZYD-FZ8014 flipping dryer, ensuring uniform air exposure via adjustable flipping (0–15 rotations/minute) with ≤3% moisture residue.

Packaging and Sterilization

Vacuum Packaging: The KBT DZ-1100 automatic packaging machine on the line supports single/multi-cob packaging, completing 60 bags/min with 99.8% sealing qualification.

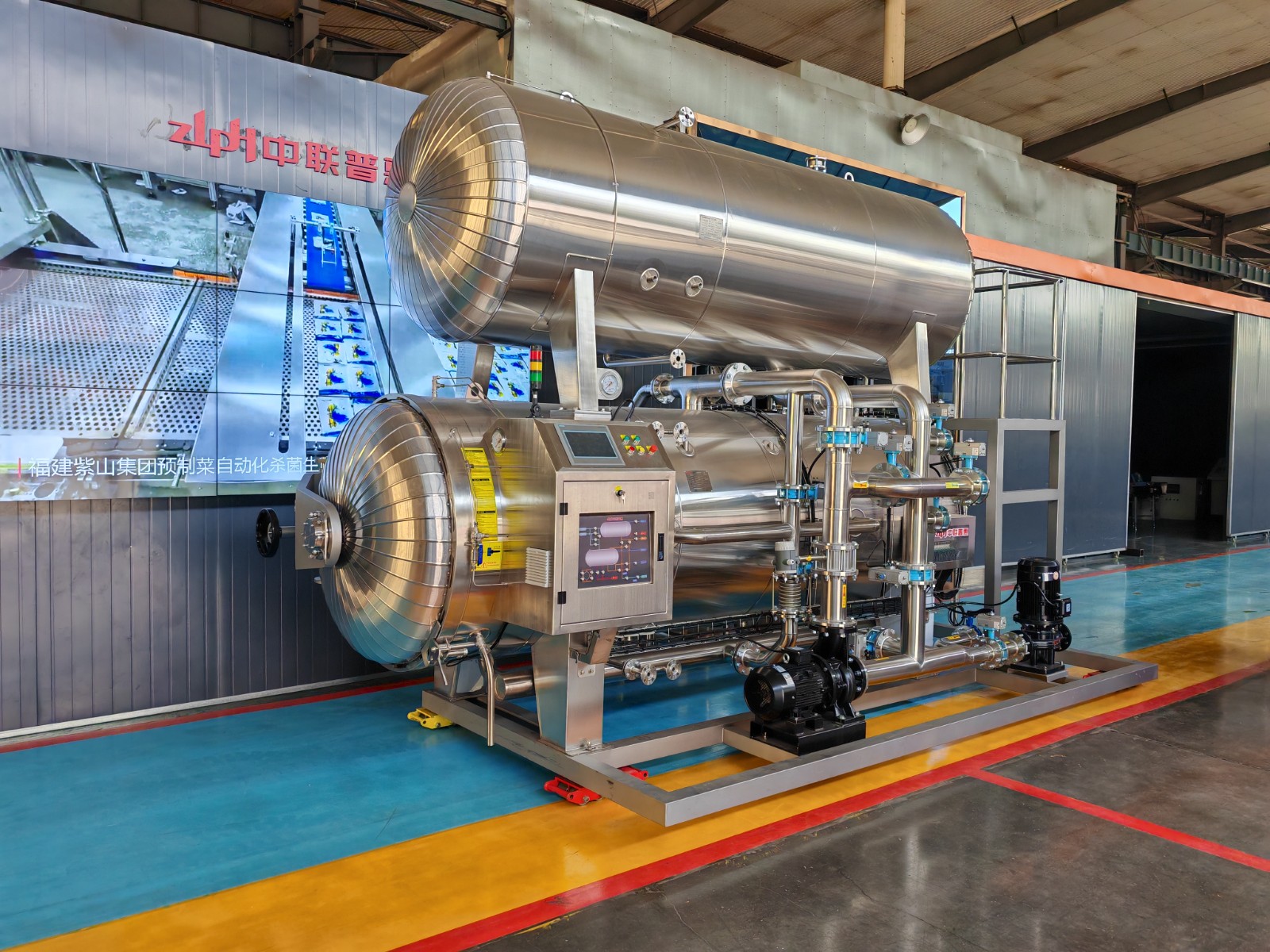

Core Sterilization Equipment: ZLPH 1500*5250 Double-Layer Water Immersion Retort

The retort’s double-layer structure processes two batches simultaneously, improving sterilization efficiency by 30% and saving 15% steam.

Water immersion sterilization in the retort ensures ±1℃ temperature uniformity; linear control maintains packaging integrity >99%.

Compliant with FDA, the retort extends shelf life to >180 days.

Post-Processing

High-pressure spraying cleans bag surfaces, and the flipping dryer avoids heat damage via room-temperature airflow. The production line’s automatic packaging machine finalizes combined boxing, sealing, and labeling.

II. Technical Advantages of Core Equipment on the Line

Air-Blowing Husker:

<5% damage rate, 25% lower energy consumption, processing 10,000–12,000 cobs/hour for large-scale production line operations.

Trimming Machine:

High-precision cutting, compatible with huskers and washers to form an integrated production line, durable for long-term use.

Retort:

Double-layer design enables automated “heating-sterilizing-cooling” on the line; rapid temperature control preserves corn texture, ideal for soft-packed cob sterilization.

III. Production Capacity and Quality Control of the Line

Capacity Indicators

Designed capacity: 4.5 tons/hour (kernels), 100 tons/day (22-hour operation).

The production line’s flexible design supports 30%–50% capacity expansion via parameter adjustment or module addition.

Quality Control System

Raw Material Inspection: Strict screening of water content, impurity rate, and kernel integrity; automatic rejection of unqualified materials.

On-Line Monitoring: Real-time tracking of post-threshing impurities (≤0.5%), post-drying moisture (≤12%), and color sorting accuracy (99.9%) on the production line.

Finished Product Inspection: Comprehensive testing of appearance, microbial indicators (total plate count ≤100CFU/g), and shelf life simulation to meet international standards.

IV. Turnkey Project Features of the Whole Line

Turnkey Project: Covers process design, equipment selection, installation, and commissioning, with a 3-year warranty and lifetime technical support.

Green Energy Saving: 85% water recycling, 20% lower steam consumption than traditional lines, complying with national environmental standards.

Customized Solutions: The production line’s layout adapts to raw material traits, capacity needs, and site conditions, with supporting 3D drawings and energy consumption analysis.

If you’re interested in learning more about our ZLPH Retort or exploring potential cooperation opportunities, feel free to reach out to us via email at saleshayley@zlphretort.com or connect with us on WhatsApp at +86 15315263754.