What Certifications Should I Pay Attention to When Purchasing a Rotary Autoclave?

When investing in a rotary autoclave, ensuring product quality, safety, and compliance with international standards is essential. Certifications are not just formalities—they are clear indicators that the equipment has passed rigorous testing for performance, safety, and durability. One leading manufacturer, ZLPH, has achieved multiple global certifications including ASME, ISO, EU CE, Russian EAC, and Malaysian Occupational Safety and Health. These certifications demonstrate the reliability and superior engineering of its rotary sterilizer and rotary retort autoclave products. Understanding these certifications will help you make a well-informed purchasing decision when selecting a high-quality rotary retort machine or autoclave retort sterilizer.

1. ASME Certification – Ensuring Pressure Vessel Safety

The ASME (American Society of Mechanical Engineers) certification is one of the most recognized standards in the world for pressure vessels. A rotary autoclave that meets ASME standards has been tested to withstand high pressure and temperature safely. This means the vessel’s materials, welding, and structure comply with the strictest mechanical and thermal design codes.

For food manufacturers, this ensures that every batch processed in a rotary sterilizer remains safe and stable under pressure, minimizing the risk of leaks or explosions. ASME certification gives buyers confidence that their rotary retort machine is built for long-term, reliable operation under demanding production conditions.

2. ISO Certification – Guaranteeing Quality Management

ISO certification, particularly ISO 9001, demonstrates that the manufacturer has established an effective quality management system. ZLPH’s ISO-certified production ensures consistent manufacturing quality, traceable production records, and continuous improvement processes.

For clients purchasing a rotary retort autoclave, ISO certification translates to dependable product quality, timely delivery, and responsive after-sales service. It confirms that every autoclave retort sterilizer undergoes strict inspection and quality control at every production stage—from material selection to final testing—ensuring global consistency and performance.

3. EU CE Certification – Compliance with European Safety Standards

The CE marking is mandatory for equipment sold in the European Union, certifying that the product meets EU health, safety, and environmental protection requirements. A rotary autoclave bearing the CE mark has been assessed to prevent risks such as electrical hazards, mechanical failures, and pressure-related incidents.

By choosing a CE-certified rotary sterilizer, users can be confident in its safety and operational reliability. This certification is especially valuable for international buyers, as it ensures smooth entry into the EU market and compliance with European regulatory frameworks for food processing equipment.

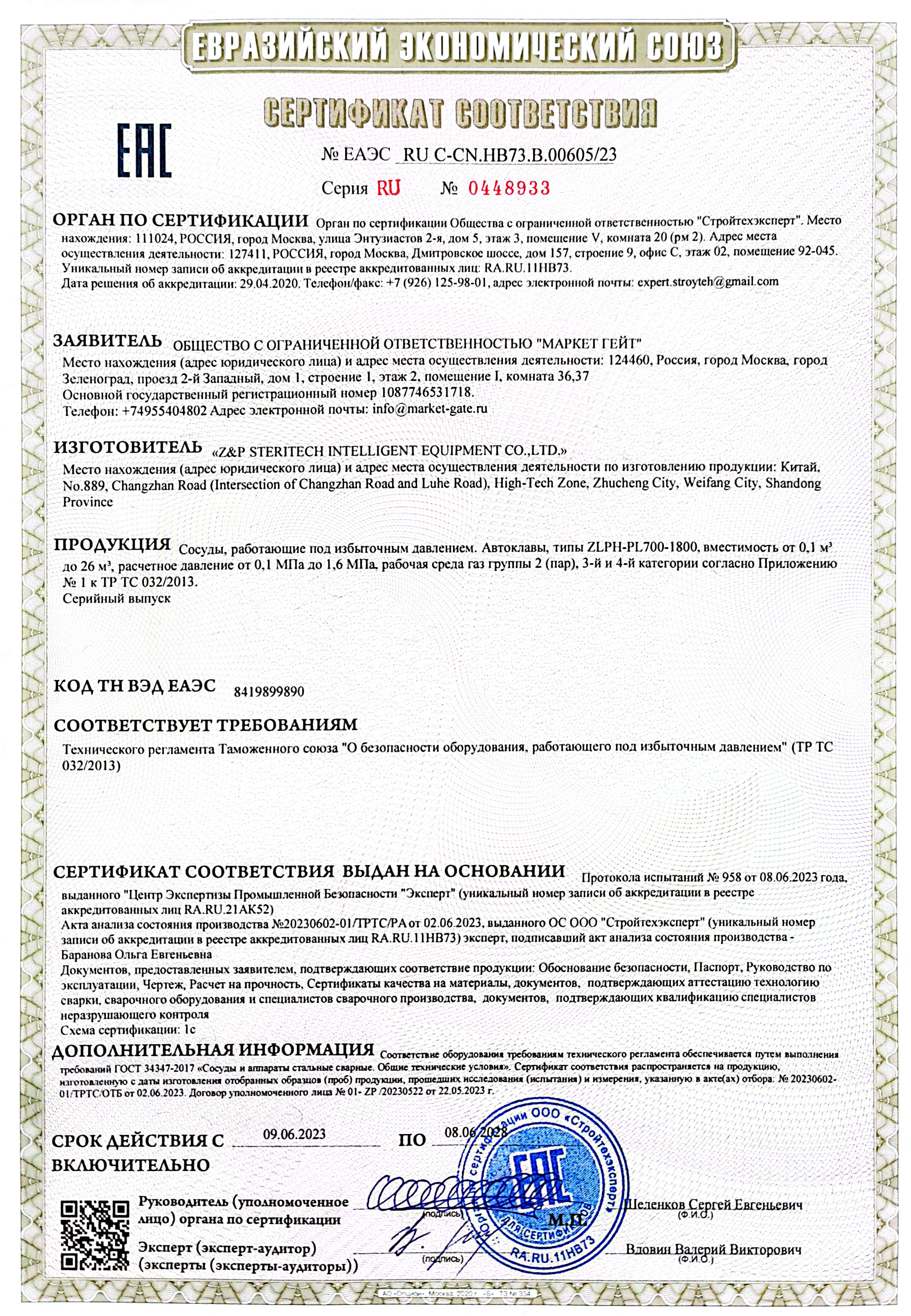

4. Russian EAC Certification – Access to the Eurasian Market

The EAC (Eurasian Conformity) certification covers compliance with the technical standards of Russia and neighboring Eurasian countries. For companies exporting or operating in these regions, selecting a rotary retort machine with EAC certification eliminates the risk of customs clearance issues and ensures conformity with regional safety regulations.

EAC certification for ZLPH’s rotary retort autoclave means that the machine has been tested for durability, performance, and operational safety under the regulatory systems of Eurasian countries. This gives manufacturers greater flexibility to expand into international markets while maintaining compliance.

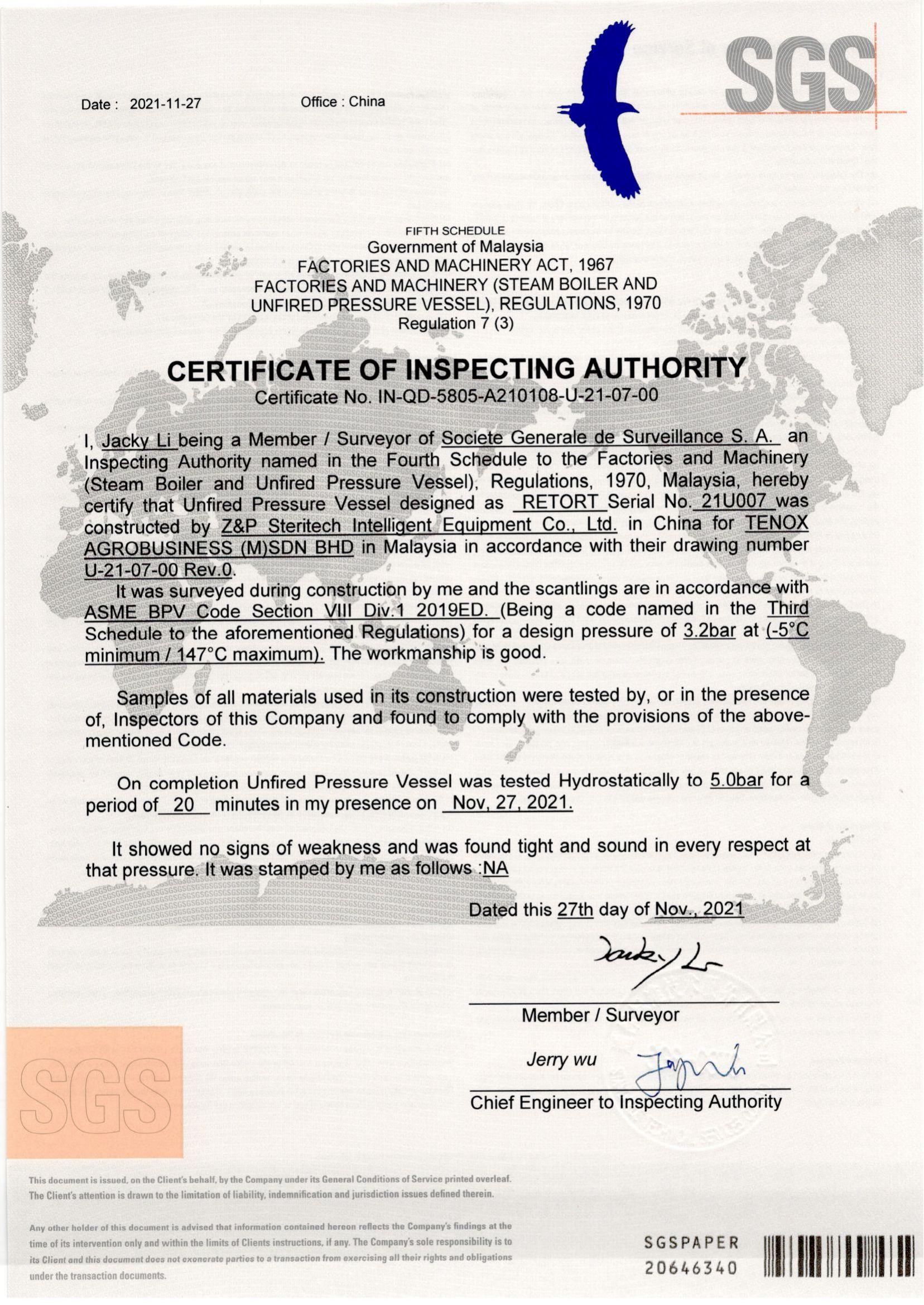

5. Malaysian Occupational Safety and Health Certification – Localized Compliance and Worker Safety

In Malaysia, the Department of Occupational Safety and Health (DOSH) certification is required for all pressure vessels, including autoclave retort sterilizers. ZLPH’s compliance with this certification demonstrates its commitment to worker safety, proper design, and safe operation under Malaysian regulations.

For food producers and industrial operators, this means the rotary autoclave not only meets international standards but also adheres to local safety laws—reducing risks during operation and ensuring legal compliance.

6. The Advantages of Certified Rotary Autoclaves

Choosing a certified rotary sterilizer or rotary retort machine offers significant advantages:

Enhanced safety: Each certification ensures the equipment can operate safely under high temperature and pressure.

Global market access: Certified machines can be legally sold and operated in multiple countries without additional approvals.

Higher product reliability: Certified manufacturing ensures consistency, durability, and performance.

Lower operational risk: Compliance with occupational safety standards protects workers and facilities.

Increased buyer confidence: Certifications reflect the manufacturer’s professionalism and technological expertise.

When purchasing a rotary retort autoclave, always check for internationally recognized certifications such as ASME, ISO, EU CE, Russian EAC, and Malaysian Occupational Safety and Health. These certifications prove that the autoclave retort sterilizer meets strict quality and safety benchmarks. Manufacturers like ZLPH, who hold all these certifications, provide buyers with peace of mind, exceptional performance, and global market compliance. In short, certified rotary autoclaves represent a smart, safe, and sustainable investment for any modern food processing operation.