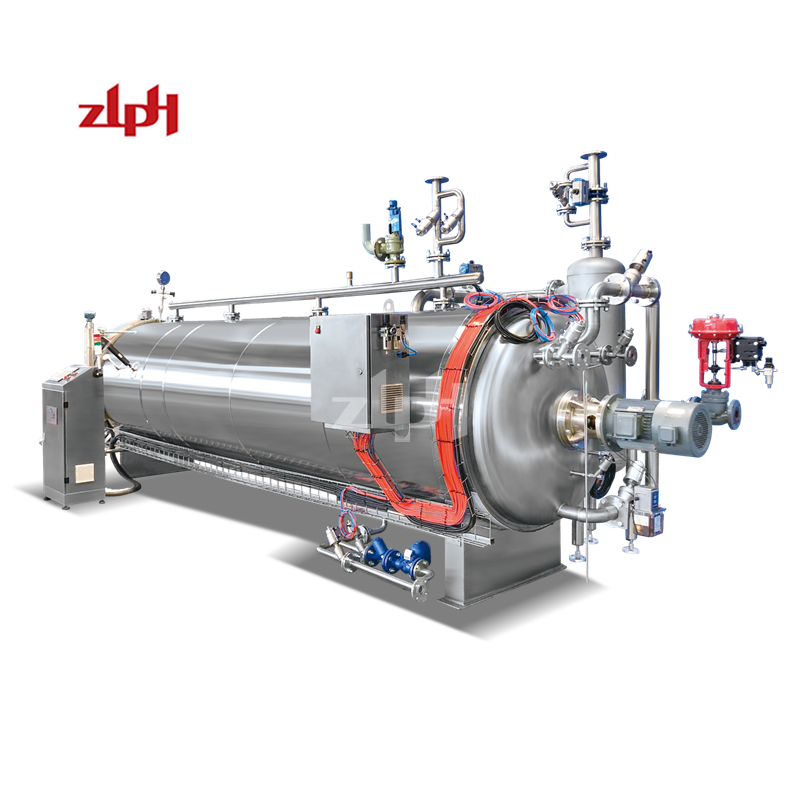

ZLPH Retort Autoclave: The Core Equipment for the product quality level Innovation of Fish Canned Food in Tinplate Cans

In the food market, fish canned food in tinplate cans is deeply favored by consumers due to its convenience, long shelf life, and unique flavor. From freshly caught sea fish to finished canned products, every link in the production and processing process affects the product product quality level, among which the sterilization link is of great significance. With its excellent performance, the ZLPH retort autoclave brings about a product quality level leap for the fish canned food industry in tinplate cans.

Efficient Sterilization to Ensure Food Safety

The raw materials of fish canned food come from the ocean, and they are prone to microbial contamination during the processes of fishing, transportation, and processing. These microorganisms can cause the canned food to deteriorate and affect its safety for consumption. The ZLPH retort autoclave applies advanced short-term high-temperature and high-pressure coordinated sterilization technology. By taking advantage of the good airtightness and thermal conductivity of tinplate cans, it precisely regulates the temperature, pressure, and time of sterilization. For example, when processing tuna canned food, it can quickly increase the temperature for sterilization, and the high pressure can destroy the structure of stubborn microorganisms. The canned food processed by it has a sterilization rate of over 99.99%, far exceeding the industry average, providing consumers with safe and reliable food.

Precise Temperature Control to Retain Flavor and Nutrition

Traditional sterilization often damages the flavor and nutrition of fish canned food due to excessive heating, making the fish less palatable and causing the loss of nutrients. The ZLPH retort autoclave is equipped with an intelligent temperature control and pressure regulation device. According to the characteristics of different fish species and the contents of the canned food, it customizes the sterilization plan. Taking sardine canned food as an example, during the sterilization process, the conditions are precisely controlled, retaining the tender taste and unique flavor of the fish. The nutrient retention rate is increased by 30%-40% compared with the traditional process, and the flavor restoration degree reaches over 90%.

Efficient Production to Enhance Enterprise Competitiveness

With the increasing market demand for fish canned food, enterprises are faced with the pressure of increasing production capacity and reducing costs. Traditional sterilization equipment has problems such as long sterilization cycles, high energy consumption, and large floor space. The ZLPH retort autoclave adopts a continuous production design, enabling uninterrupted sterilization of fish canned food. For the mackerel canned food production line, for instance, compared with traditional batch sterilization equipment, the hourly processing capacity is increased by 2-3 times, shortening the production cycle. At the same time, it has low energy consumption, saving operating costs, and its compact design also saves production space, comprehensively enhancing the competitiveness of enterprises.

Stable product quality level to Establish a Good Brand

Stable product product quality level is crucial for enterprises. The product quality level of different batches of fish canned food may vary due to fluctuations in raw materials and processes, affecting the brand image. Relying on standardized processes and an automated control system, the ZLPH retort autoclave can accurately replicate each sterilization process. Regardless of changes in raw materials, it can ensure that products of each batch reach a unified high-product quality level standard, helping enterprises establish a good brand and win the trust of consumers.

In the development process of the fish canned food industry in tinplate cans, the ZLPH retort autoclave, with its advantages such as efficient sterilization, retention of flavor and nutrition, improved production efficiency, and stable product quality level, has become a key force driving the product quality level innovation of the industry. With the continuous innovation of technology, it will provide more support for fish canned food production enterprises, help them bring more high-product quality level products to consumers, and lead the industry to a new height.