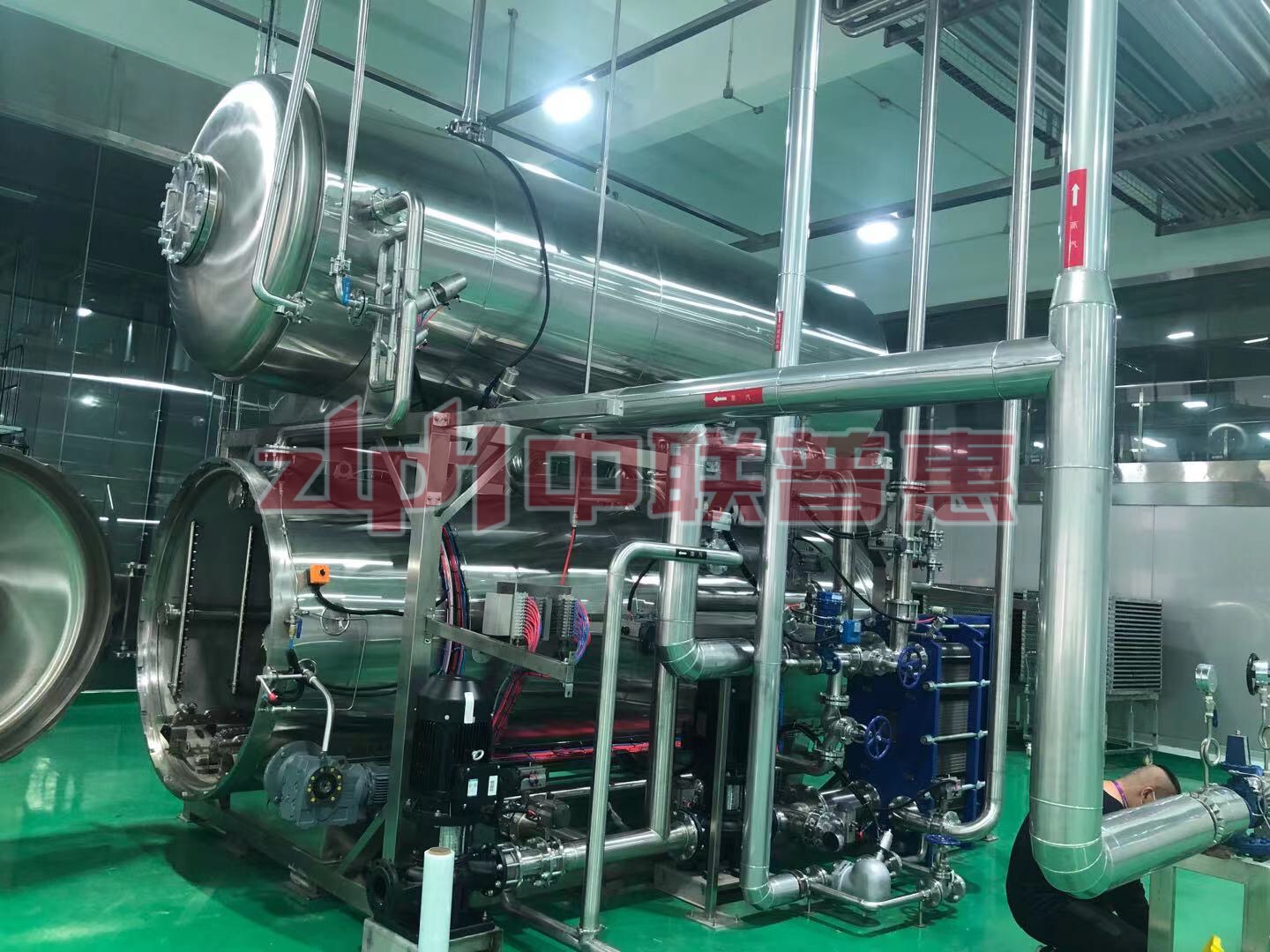

ZLPH Retort: Ensuring the Safety of Health Product Oral Liquids

Under the strict requirements of the health product industry for production safety and product quality, ZLPH Company, with technological innovation at its core, has launched a new generation of retorts. Through the deep integration of four core modules, namely intelligent operation, linear temperature control, pressure balance, and safety redundancy, it has achieved a dual breakthrough in sterilization effect and packaging protection, helping enterprises to produce efficiently and in compliance with regulations.

Core Advantages: Empowered by Technology, Redefining Sterilization Standards

1. Intelligent PLC Operation, One-click Automated Production

Equipped with an industrial-grade PLC intelligent control system, it supports one-click startup and full-process automated operation. Users only need to preset sterilization parameters (temperature, pressure, time, etc.), and the system can automatically complete the whole process operations such as heating up, heat preservation, cooling, and pressure regulation, greatly reducing manual intervention and improving production efficiency and stability. The system has a built-in process database that can store and call historical parameters to achieve standardized production and ensure the consistency of product quality in each batch.

2. Linear Temperature Control Technology with an Accuracy of 0.2℃, Preserving Thermosensitive Ingredients Strictly following the requirements of FDA regulations (21CFR), the linear heating-up control technology is adopted, and the heating-up rate and temperature curve can be precisely regulated with a control accuracy of ±0.2℃. This design effectively avoids the common "temperature overshoot" problem in traditional sterilization equipment, and maximally preserves the thermosensitive ingredients (such as vitamins, probiotics, etc.) in the oral liquid, meeting the dual pursuit of "safety and nutrition" in the health product industry.

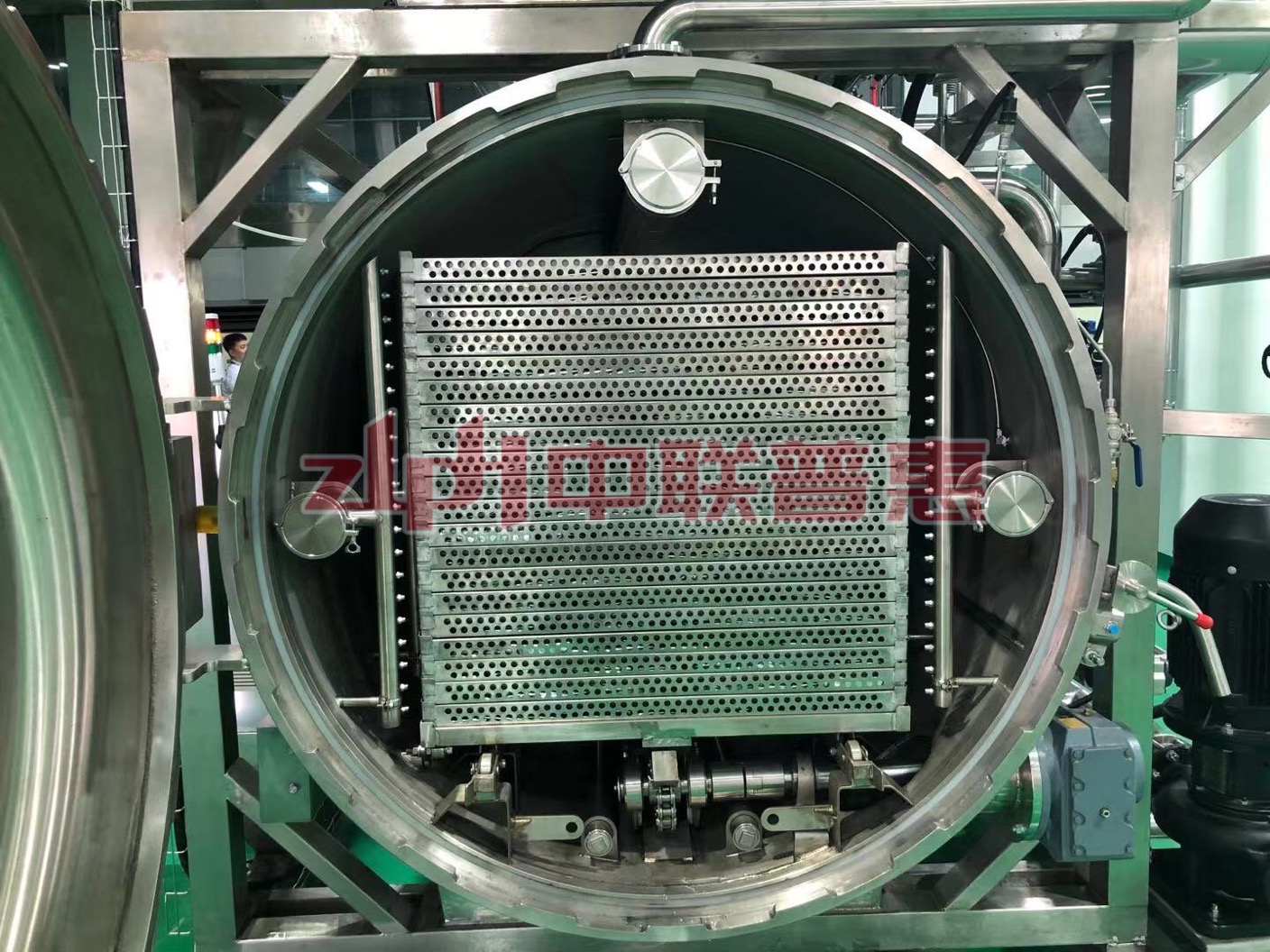

3. Pressure Balance System, Indirect Heating/Cooling, Protecting Packaging Integrity

An innovative integrated design of indirect heating and indirect cooling is adopted. The precise regulation of the temperature inside the tank is achieved through a heat exchanger to avoid local overheating or overcooling caused by direct contact. At the same time, the system can linearly control the pressure inside the tank. By adjusting the flow rate of steam or cooling water in real time, the pressure inside the tank is kept in dynamic balance with the external environmental pressure, effectively preventing the packaging from swelling, bursting or deforming due to pressure fluctuations, and ensuring the integrity of the product appearance and tightness.

4. Large-flow Removable Filter + Flow Monitoring, Ensuring the Stability of the Circulation System

Aiming at the problem that the fluctuation of the circulating water flow during the sterilization process may affect the sterilization effect, the ZLPH retort innovatively adopts a large-flow removable filter combined with a real-time flow monitoring device to achieve intelligent constant control of the circulating water volume. When the flow is lower than the set value, the system will automatically alarm and start the self-cleaning program to avoid uneven sterilization caused by blockage or insufficient flow, ensuring that the product meets the aseptic standard.

5. Redundant Dual-sensor System, Double Insurance for Production Safety

To ensure the safety and reliability of the sterilization process, the ZLPH retort adopts a redundant dual-sensor design in key sensor systems such as temperature and pressure. Two sets of independent sensors monitor the same parameter in real time. When the main sensor fails, the system will automatically switch to the backup sensor and trigger an alarm prompt to avoid production accidents caused by sensor failure. In addition, the sensor data can be synchronously uploaded to the cloud for remote monitoring and data analysis.

Application Scenarios: Full-process Coverage, Empowering Enterprises for Efficient Production

Research and Development Verification: The ZLPH laboratory-specific retort supports small-batch and multi-batch rapid tests, helping enterprises quickly verify the impact of different sterilization processes on the stability and active ingredients of oral liquids and accelerating product formula optimization.

Pilot Production: The pilot-scale retort simulates industrial production conditions to ensure that the process parameters can be seamlessly scaled up to large-scale production, reducing the risk of technology transfer.

Large-scale Mass Production: The fully automatic retort can be linked with the filling line and packaging line to achieve continuous and automated production. The single-batch processing capacity reaches thousands of bottles, meeting the rapidly growing demand of the health product market.

ZLPH retort: Empowered by Technology, Driving Industry Compliance Upgrades

Compliance Assurance: Strictly following international standards such as FDA, GMP, and HACCP, it helps enterprises pass international certifications and expand into the global market.

Customized Services: Provide personalized process design according to customers' needs, including sterilization curve optimization, thermosensitive ingredient protection solutions, etc., to meet the differentiated needs of different oral liquids.

Full Lifecycle Service: ZLPH provides one-stop services from equipment selection, installation and commissioning to after-sales maintenance to ensure the long-term stable operation of the equipment.

Conclusion: ZLPH retort, Safeguarding Every Health Commitment with Technology

In the competitive landscape of the health product industry where "quality is life", the ZLPH retort, with its four core advantages of intelligent operation, precise temperature control, pressure balance, and safety redundancy, has become an ideal choice for enterprises to improve production efficiency, ensure product safety, and achieve compliant production. In the future, ZLPH will continue to deepen its research in the field of sterilization technology, drive development through innovation, and work hand in hand with global partners to jointly promote the health industry towards a higher quality and more sustainable future.

Choosing the ZLPH retort means choosing a guarantee of safety, efficiency and quality!