ZLPH Water Spray Rotary Sterilizer | Rotary Sterilizer

The intelligent rotary water spray sterilizer is a rotary sterilizer with a spray device added to it. It is an indirect heating and indirect cooling. The sterilization process water and cooling water are not in direct contact, avoiding secondary pollution of the product. No water treatment chemicals are required. A small amount of process water is continuously circulated to complete the heating, sterilization and cooling process of the product, which can save 15% of steam. The temperature and pressure can be linearly controlled to achieve the effect of balancing the pressure inside and outside the tank. There are water spray devices on the upper part of the retort and the rotating body. When rotating, water is evenly sprayed around the material basket to ensure the heat penetration effect and the uniformity of heat distribution. While ensuring the stability of the sterilization effect, it also ensures that the product packaging is not damaged.

There is a hot water storage tank on the top with a heating function to realize water preheating. The water storage capacity of each storage tank can be used for sterilization, ensuring the continuity of the equipment operation.

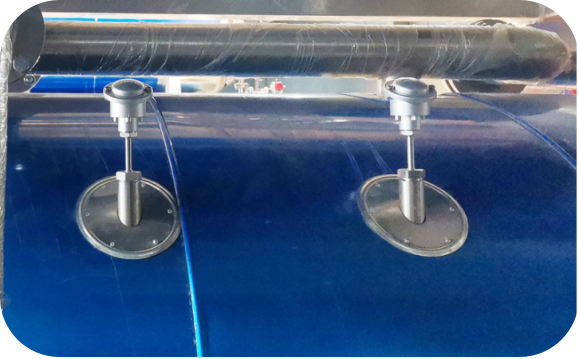

Due to the existence of the cage, part of the water will be blocked by the cage during full spray sterilization, especially the cylinder and basket gland part. In order to make this new full-spray rotary cage sterilizer have better heat distribution, we have carried out a series of special designs, distributed the nozzles in a certain proportion in the pot, arranged them reasonably, formed a perfect spray effect, and ensured that there were no dead corners in the food basket, thus ensuring the heat distribution effect.

We select high-quality 304 stainless steel, and after laser cutting, we semi-finish it first, and then weld and assemble it into parts. After aging and vibration to eliminate internal stress, the prototype of the assembled rotating body will be placed outdoors for about 72 hours, and then aging and vibration will be carried out to eliminate welding internal stress. Finally, it will be formed in one go using a machining center to ensure the concentricity of the axis and the rotating body during the rotation process.

Use pneumatic diaphragm valve for precise temperature control, the PID can automatically adjust the opening size according to temperature changes, and the temperature control is more accurate (diaphragm valve temperature control ±0.1℃, heat distribution control accuracy ±0.5℃)

Our retort advantage

Overpressure protection

Double safety valve mechanical overpressure protection sterilizer safe to use,avoiding personnel danger.

Temperature Control

The membrane valve accurately controls the temperature and automatically adjusts the opening amount.

Dual temperature pressure

Equipped with dual temperature and dual pressure control functions to prevent sensor failure from affecting use.

Nozzle optimization

Nozzle optimization design to form a perfect spray effect,Arrange reasonablyEnsure heat distribution effect.