We express our profound appreciation to our esteemed Vietnamese distribution partner for the exceptional trust and steadfast support demonstrated in bringing ZLPH Machinery's specialized thermal processing solutions to the Southeast Asian market. Your unwavering commitment and dedicated market development efforts have been instrumental in introducing our precision-engineered Bird's Nest Sterilization systems to enterprises throughout the region, establishing new benchmarks for product quality and processing efficiency in this specialized sector.

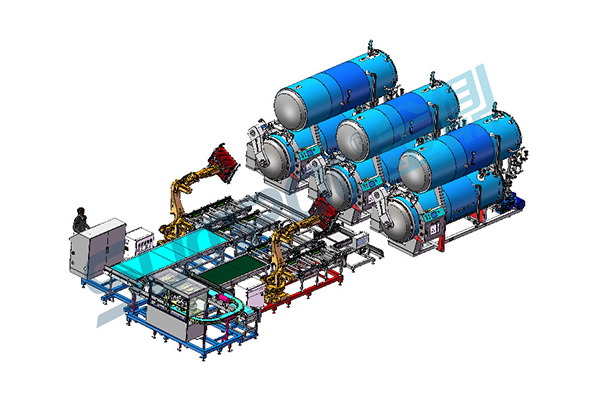

At ZLPH Machinery, we recognize that premium bird's nest products demand exceptionally sophisticated processing methodologies. The delicate cellular structure and valuable nutritional components of edible bird's nests require sterilization technologies that balance thorough microbial elimination with precise thermal control. This is precisely where our advanced Retort Autoclave systems demonstrate their technical superiority. Each unit incorporates proprietary multi-zone thermal regulation technology that ensures uniform temperature distribution throughout the processing chamber, a critical factor when dealing with the unique physical characteristics of bird's nest materials.

The scientific principles underlying retort sterilisation represent the foundation of our technological approach. Our engineering team has developed specialized processing protocols that account for the specific density, moisture content, and packaging formats typical of premium bird's nest products. The Retort Machine configurations we provide for this application feature enhanced pressure compensation mechanisms that prevent structural damage to delicate nest filaments while ensuring complete microbial eradication. This sophisticated equilibrium between sterilization efficacy and product preservation distinguishes ZLPH solutions in the marketplace.

Our technical capabilities extend significantly beyond standard equipment manufacturing. We have pioneered adaptive control systems for our retort autoclave units that automatically adjust processing parameters based on real-time sensor data, ensuring batch-to-batch consistency that manual operations cannot achieve. This technological sophistication is particularly valuable for bird's nest processors targeting export markets with stringent quality requirements and documentation demands. The integration of Industry 4.0 principles into our sterilization equipment enables complete process traceability, with automated data logging systems that generate comprehensive documentation for regulatory compliance and quality assurance purposes.

The collaboration with our Vietnamese partner exemplifies our commitment to comprehensive market support. Beyond equipment supply, we have established a technical knowledge transfer framework that includes specialized training programs focused on optimal Bird's Nest Sterilization practices. Our regional technical specialists work closely with distributors and end-users to develop customized processing profiles that maximize both equipment performance and final product quality. This collaborative approach ensures that every Retort Machine installation operates at peak efficiency while maintaining the delicate balance between thorough sterilization and nutritional preservation that defines premium bird's nest products.

Our production excellence is matched by our service responsiveness. ZLPH Machinery maintains a dedicated technical support network with multi-lingual capabilities, ensuring prompt assistance for operational queries, maintenance requirements, or process optimization challenges. This responsive support structure, combined with strategically located spare parts inventories, minimizes operational downtime and maximizes production continuity for our partners throughout the region.

The market success achieved through our Vietnamese collaboration underscores the effectiveness of our partnership model. By combining ZLPH's technological innovation with our distributor's market expertise and customer relationships, we have created a powerful synergy that delivers measurable value to bird's nest processors. This cooperative approach has enabled regional enterprises to enhance their production capabilities, improve product consistency, and access more sophisticated markets with confidence in their quality management systems.

Looking forward, we remain committed to advancing thermal processing technology specifically for delicate, high-value products like bird's nests. Our ongoing research and development initiatives focus on energy optimization, sustainable processing methodologies, and enhanced automation features that will continue to redefine industry standards. The success achieved in Vietnam provides a proven model for expansion into complementary markets with similar processing requirements for delicate organic materials.

We extend our deepest gratitude to our Vietnamese partners for their instrumental role in this success story. Your market insight, customer relationships, and implementation expertise have been invaluable in demonstrating how advanced retort sterilisation technology can transform traditional processing methodologies. Together, we are establishing new paradigms of efficiency, quality, and reliability in bird's nest production—creating tangible value for processors while ensuring end consumers receive products of uncompromised purity and nutritional integrity.

As we continue this productive partnership, ZLPH Machinery reaffirms our commitment to technological innovation, manufacturing excellence, and collaborative market development. We look forward to further successes together, expanding the positive impact of advanced thermal processing technology across the region's food processing sector and beyond.

Retort Machine

retort autoclave

Bird's Nest Sterilization

retort sterilisation