Retort processing stands as the foundational technology in modern food manufacturing, enabling the safe, large-scale production of shelf-stable ready-to-eat (RTE) meals that require no refrigeration. This advanced thermal Commercial Sterilization method, executed within a precision retort autoclave, has transformed the global food industry by reliably meeting demands for convenient, safe, and nutritious packaged foods.

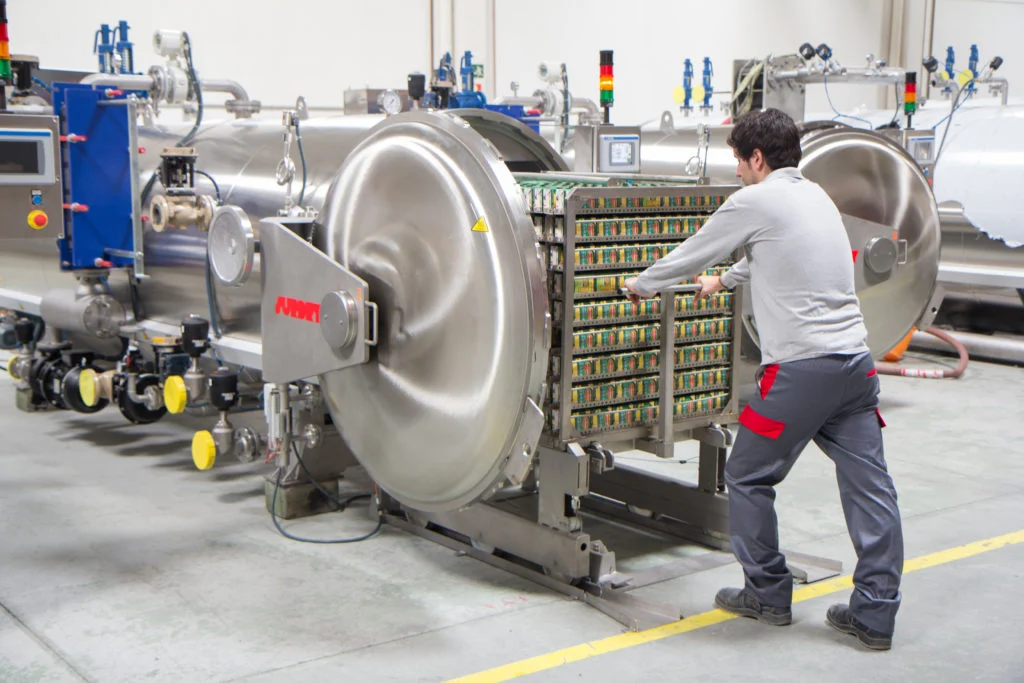

At its core, retort processing involves subjecting hermetically sealed food containers to controlled high temperatures and pressures inside specialized pressure vessels. This critical step in a retort food machine achieves true Commercial Sterility by eliminating all pathogenic and spoilage microorganisms. The technology's key distinction lies in its ability to sterilize products after final packaging within the retort machine, thereby preventing any risk of recontamination. This makes the modern food retort machine indispensable for producing complex, multi-component meals with guaranteed safety and extended ambient shelf life.

The advantages of implementing a retort autoclave system are substantial. Beyond ensuring exceptional food safety, the technology offers remarkable versatility. A state-of-the-art retort machine can accommodate diverse container formats—from flexible pouches and trays to traditional cans and glass jars—making it a universally adaptable retort food machine solution. Advanced systems provide precise multi-zone temperature and pressure control, automated process monitoring for full regulatory compliance, and integrated energy recovery systems that significantly reduce operational costs, enhancing the overall efficiency of the food retort machine.

Common industrial systems include several retort autoclave types, each serving specific production needs. Static steam retorts offer a traditional, cost-effective solution for cans and jars. Water immersion and spray systems, a versatile form of retort food machine, provide gentle, uniform heating ideal for flexible packaging. Rotary retorts act as a dynamic retort machine, enhancing heat transfer for faster processing times through container agitation. For the highest volume output, continuous retort autoclave systems represent the pinnacle of automated Commercial Sterilization efficiency.

The success of the Commercial Sterilization process hinges on two critical factors managed by the retort food machine: product formulation and container selection. The product's pH level dictates the processing severity within the retort machine, with low-acid foods requiring the most rigorous treatment in the food retort machine. Intelligent ingredient selection, including the use of modified starches and stabilizers, is crucial for maintaining optimal texture and consistency post-processing. Simultaneously, container selection—whether metal, glass, or flexible laminate—directly impacts the heat penetration efficiency in the retort autoclave, balancing processing performance with consumer convenience and supply chain durability.

As global consumer demand for high-quality, convenient RTE meals continues to accelerate, retort processing secured by a reliable retort machine remains more essential than ever. It represents a perfect synergy of proven Commercial Sterilization safety with continuously evolving technological capabilities. The modern retort autoclave is not merely a sterilizer; it is a sophisticated food retort machine that ensures the delivery of nutritious, long-lasting, and safe food products to consumers worldwide, solidifying its role as the indispensable cornerstone of contemporary food manufacturing infrastructure. Investing in the right retort food machine technology is therefore a strategic decision for any brand committed to quality, safety, and market growth.