The common portrayal of urbanites is "7 o'clock subway, 8 o'clock meeting, and still replying to WeChat in the early morning." Staying up late, taking out food, sitting for long periods of time, and anxiety have made "sub-health" no longer an adjective, but a high-frequency term in medical examination reports. When "soaking goji berries in a thermos" was upgraded to "carrying oral liquid in a carry-on bag," medicinal and edible drinks quickly became popular due to their "delicious and nourishing" nature. However, this popularity brought new questions: How do we ensure that bottles of "plant extract" remain safe without adding preservatives and reach consumers in perfect condition?

Spray Technology: How It Works

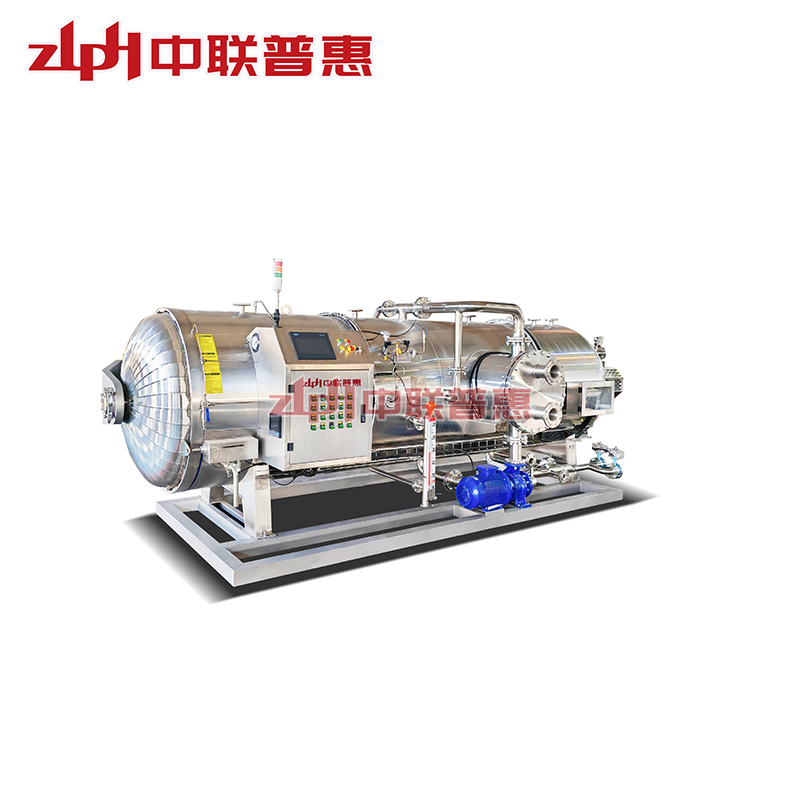

Modern enterprises find particular reassurance in the ZLPH spray retort autoclave's intelligent control systems. This advanced food retort machine incorporates PLC modules that upload real-time temperature, pressure, and F0 values to cloud-based monitoring platforms, enabling quality personnel to access batch reports anytime, anywhere. If parameters deviate from specifications, the system automatically triggers alarms and can initiate shutdown procedures. A prominent mulberry hawthorn oral liquid brand sold over ten million units in its first month without a single complaint regarding bottle expansion or flocculent appearance. Company leadership noted, "Consumers appreciate the aesthetically pleasing bottle, while we trust the invisible protection provided by ZLPH's retort packaging machine technology." This retort canning machine system represents the convergence of precision engineering and digital oversight that defines modern pharmaceutical-grade processing equipment.

Technical Superiority: Why Spray Retort Technology Excels

The ZLPH spray retort autoclave outperforms conventional sterilization methods through several key technological advantages. Unlike traditional retort machine systems that rely on water immersion or steam, the spray technology ensures uniform heat distribution without creating thermal gradients that can damage sensitive products. The precision nozzles in this food retort machine create a consistent mist envelope around each container, eliminating cold spots that might compromise sterility while preventing localized overheating that degrades product quality. This retort packaging machine innovation particularly benefits products containing heat-sensitive bioactive compounds that would deteriorate under conventional thermal processing. Compared to standard retort canning machine technologies, the spray system reduces processing time by up to 60% while improving sterility assurance levels—a combination previously considered unachievable for delicate medicinal beverages.

Meeting Modern Consumer Expectations

Today's health-conscious consumers demand products that combine safety, efficacy, and sensory appeal. The ZLPH spray retort autoclave enables manufacturers to meet these elevated expectations by preserving the very qualities that make medicinal beverages appealing. This advanced food retort machine maintains the vibrant colors, delicate aromas, and nuanced flavors that define premium oral liquids while ensuring complete microbial safety. In an era where clean labeling and natural preservation methods command market premiums, this retort packaging machine technology provides the perfect solution: extended shelf life without chemical preservatives, maintained potency without degradation, and commercial sterility without compromise. The retort canning machine achieves what conventional methods cannot—true "clean label" preservation that aligns with contemporary wellness trends.

Economic Advantages for Manufacturers

Beyond quality preservation, the ZLPH spray retort autoclave delivers compelling economic benefits that justify investment. This advanced retort machine technology reduces energy consumption by up to 40% compared to traditional retort systems through optimized heat transfer and reduced processing times. The extended shelf life enabled by this food retort machine significantly expands distribution reach and reduces product returns due to spoilage. Manufacturers utilizing this retort packaging machine report reduction in product losses exceeding 30% compared to conventional methods. The retort canning machine further contributes to operational efficiency through automated processing cycles that reduce labor requirements while improving batch-to-batch consistency. These combined advantages typically deliver return on investment within 12-24 months, making the technology economically accessible even for mid-sized producers.

Regulatory Compliance and Validation Support

In the strictly regulated nutraceutical and pharmaceutical sectors, compliance documentation and process validation represent critical considerations. The ZLPH spray retort autoclave includes comprehensive validation support packages that streamline regulatory approval processes. This sophisticated food retort machine generates detailed sterilization records with complete temperature mapping data, F0 value calculations, and pressure profiles that meet stringent international standards. The retort packaging machine system facilitates easy validation through its precisely controlled and repeatable processes, while the retort canning machine components are constructed from regulatory-approved materials suitable for pharmaceutical applications. Manufacturers benefit from reduced validation timelines and enhanced audit readiness when implementing this advanced retort machine technology.

Sustainability Considerations

Environmental responsibility increasingly influences equipment selection decisions in modern manufacturing. The ZLPH spray retort autoclave addresses sustainability through multiple design innovations. This food retort machine reduces water consumption by approximately 70% compared to traditional water immersion retorts through closed-loop circulation and efficient spray technology. Energy efficiency improvements lower carbon footprints while reduced processing times decrease overall energy requirements per batch. The retort packaging machine design minimizes chemical usage for cleaning and maintenance, while the durable construction of this retort canning machine ensures extended service life with minimal resource consumption for repairs or replacements. These environmental benefits complement the economic advantages, creating a compelling sustainability profile for forward-thinking manufacturers.

Future Developments in Retort Technology

The ZLPH spray retort autoclave represents just the beginning of innovation in gentle thermal processing. Future developments in food retort machine technology will likely incorporate artificial intelligence for predictive process optimization, adaptive learning systems that automatically adjust parameters based on real-time product feedback, and enhanced connectivity for fully integrated smart factory applications. Next-generation retort packaging machine systems may feature even finer mist control, multi-zone temperature management, and advanced sensors for non-invasive quality monitoring during processing. The evolution of retort canning machine technology continues toward greater precision, efficiency, and adaptability—ensuring that delicate products like medicinal beverages receive optimal preservation while meeting increasingly stringent safety standards.

Implementation and Integration Considerations

Successfully implementing spray retort technology requires careful planning and integration. The ZLPH spray retort autoclave typically interfaces with existing filling and packaging lines, though optimal results require attention to container design, filling parameters, and upstream processing conditions. This advanced food retort machine operates most effectively with consistent initial product temperatures and fill levels, while the retort packaging machine components work optimally with standardized container dimensions. Training personnel on the distinctive operating principles of this retort canning machine technology ensures maximum benefit realization, particularly regarding maintenance protocols for spray nozzles and filtration systems. Most manufacturers transition gradually, initially dedicating one production line to the new technology before expanding implementation based on demonstrated results.

Redefining Preservation for Medicinal Beverages

Fast-paced modern life rarely offers pause, but a bottle of safe, potent, nutritionally intact oral liquid that maintains its original color, aroma, and taste can provide essential "recharging" moments. The ZLPH spray retort autoclave leverages advanced technology to maintain the "freshness" of medicinal products, ensuring that health preservation no longer requires shelf-life compromises. This revolutionary food retort machine enables today's busy consumers to enjoy wellness beverages anytime, anywhere, with complete confidence in both safety and quality. As the nutraceutical industry continues evolving toward more sophisticated, delicate formulations, innovative retort packaging machine technologies like the ZLPH spray system will play increasingly vital roles in bridging traditional wisdom with modern safety standards. This advanced retort canning machine represents more than equipment—it embodies a new paradigm in preservation that honors both the science of safety and the art of quality, ensuring that every sip delivers exactly what health-conscious consumers seek: efficacy without compromise, tradition enhanced by innovation, and wellness preserved in its most perfect form.