In the competitive landscape of Ready-to-Eat (RTE) meals, achieving the perfect balance of safety, quality, and scalability is paramount. ZLPH MACHINERY engineers this balance with our advanced thermal processing systems, transforming your production into a model of efficiency and reliability. Our core technology, the autoclave retort sterilizer, is not merely equipment—it is the foundation for your brand's integrity and market success.

1. Guarantee Absolute Food Safety & Achieve Extended Shelf Life

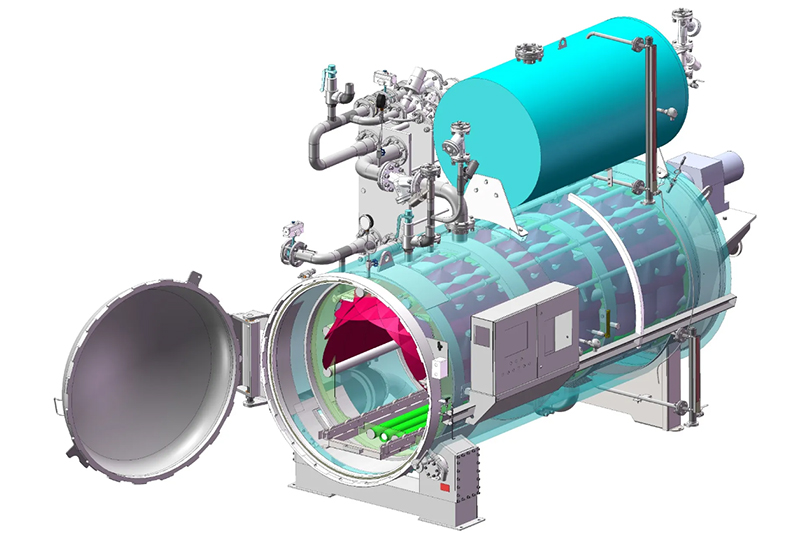

The core mission of any RTE operation is uncompromising safety. Protein and moisture-rich meals are ideal vectors for microbial growth, including resilient pathogens like C. botulinum. ZLPH MACHINERY's retort autoclave systems deliver definitive protection by creating a controlled environment exceeding 121°C under precise pressure. This process achieves commercial sterility, completely inactivating all microorganisms and spores. The result is the elimination of food safety risks and the extension of product shelf life from mere days to 12-24 months, enabling secure mass production, global distribution, and flexible storage without dependency on intensive cold chains.

2. Maximize Food Quality & Flavor Integrity Through Precision Engineering

Beyond safety, consumer satisfaction hinges on superior quality. Unlike crude thermal methods, a ZLPH retort machine utilizes exacting pressure and temperature controls. Our engineers help you customize sterilization parameters (F-values) for specific product matrices—whether delicate seafood, robust meats, or sensitive sauces. This scientific approach minimizes thermal exposure, preserving critical attributes: vegetables retain firmness, meats stay juicy, and broths maintain their just-cooked freshness. By integrating with our retort packaging machine or retort canning machine, the entire process from filling to final sterilization is optimized for peak sensory and nutritional quality.

3. Enhance Production Flexibility & Unleash Product Innovation

ZLPH MACHINERY empowers your R&D. The safety assurance provided by our autoclave retort sterilizer liberates you to explore diverse, complex formulations. From chunky stews and oil-based pasta sauces to gourmet grain bowls, our technology reliably stabilizes multi-component meals without compromising integrity. This flexibility, supported by both our retort packaging machine for pouches/trays and retort canning machine for metal/glass containers, allows you to rapidly respond to market trends and expand your product portfolio with confidence.

4. Drive Economic Efficiency & Sustainable Profitability

Our systems are engineered for your bottom line. The extended shelf life facilitated by the retort autoclave enables cost-effective batch production, reducing per-unit costs. It dramatically cuts losses from spoilage and returns. Furthermore, the ability for ambient storage and transportation slashes energy-intensive cold chain logistics expenses. The high throughput and automation of a ZLPH retort machine streamline operations, reducing labor costs and maximizing your plant's overall equipment effectiveness (OEE), delivering a compelling return on investment.

Why ZLPH MACHINERY is Your Strategic Partner

With over 17 years of specialized expertise, ZLPH MACHINERY is a leader in thermal processing technology. We provide more than a retort machine; we deliver a total solution:

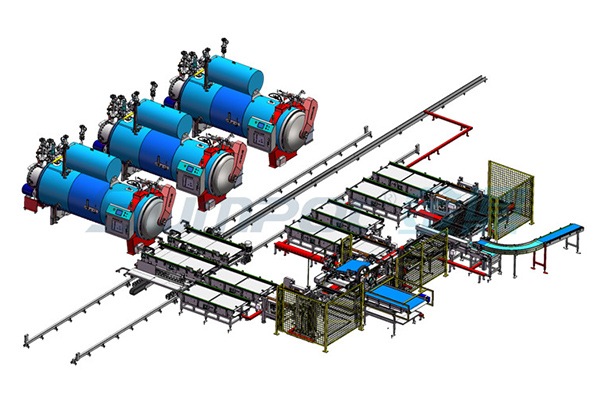

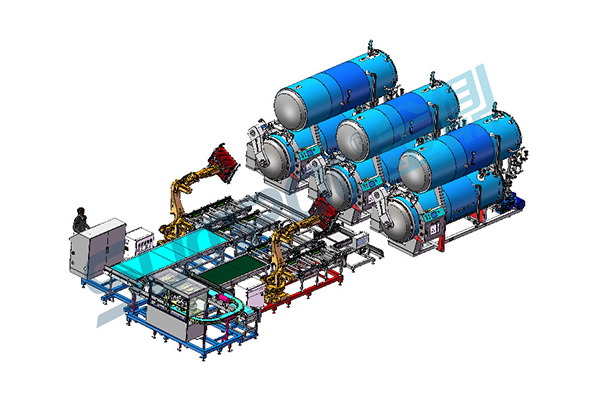

Turn-Key Systems: From standalone autoclave retort sterilizer units to complete lines with integrated retort packaging machine and retort canning machine solutions.

Global Compliance: Our systems are designed to meet the strictest international standards (FDA, EU, ISO).

Lifetime Support: We partner with you for the long term, offering comprehensive training, process validation, and technical support.

For the RTE industry, a ZLPH MACHINERY retort autoclave is the ultimate strategic asset: a guardian of safety, a pillar of quality, an engine of innovation, and an amplifier of profitability.