What Maintenance and Cleaning Routines Are Required for the Autoclave’s Rotating System and Basket Drive?

In modern food processing, the retort autoclave plays a crucial role in ensuring safe and efficient sterilization. Among its most vital components are the rotating system and basket drive—mechanisms that enable uniform heat distribution and consistent product quality. Regular maintenance and cleaning of these parts are essential not only for extending the service life of the equipment but also for ensuring the reliability of every sterilization cycle.

1

Importance of Maintaining the Rotating System

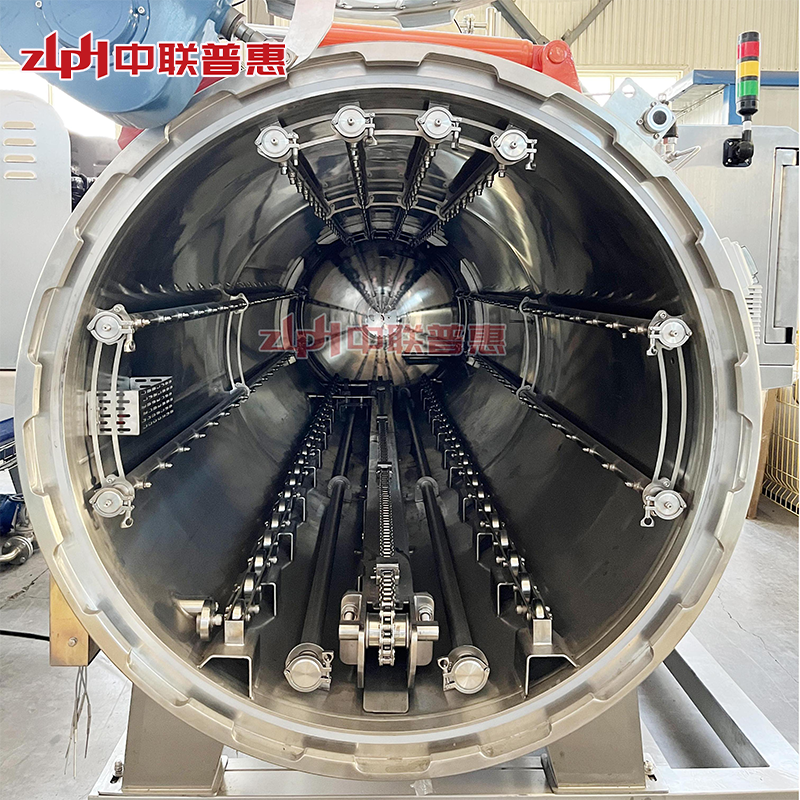

The rotating system of a retort autoclave ensures that the containers—whether pouches, cans, or glass jars—rotate evenly during sterilization. This constant motion promotes even heat transfer, preventing cold spots and ensuring every product reaches the correct temperature. However, continuous rotation under high temperature and pressure conditions places significant stress on the bearings, gears, and shafts.

Neglecting regular inspection of these components can lead to uneven rotation, increased vibration, or even mechanical failure. In a rotary sterilizer, these issues could compromise product safety and cause downtime. Therefore, operators should perform scheduled lubrication, tension adjustments, and vibration checks to maintain consistent performance of the rotary retort machine.

2

Routine Inspection and Lubrication

A detailed maintenance schedule should include weekly and monthly inspections. Bearings and gear assemblies in the rotary retort autoclave must be lubricated using high-temperature-resistant grease approved by the manufacturer. Excessive lubrication can attract debris, while insufficient lubrication can cause wear and noise.

Additionally, the motor drive and transmission belts that power the rotation mechanism should be checked for alignment and tension. Any misalignment in the autoclave retort sterilizer drive system may cause energy loss or uneven basket rotation. Replacing worn belts and tightening loose bolts ensures smooth and safe operation.

3

Cleaning Procedures for the Basket Drive and Internal Components

The basket drive system is directly exposed to moisture, steam, and food residue during operation. After each sterilization cycle, the interior of the rotary sterilizer should be rinsed with clean water to remove any remaining food particles or chemical residue. Using mild detergents prevents corrosion of stainless steel surfaces while ensuring hygiene compliance.

At the end of each production day, operators should disassemble the basket clamps, rotation shafts, and guide rails for thorough cleaning. In a rotary retort machine, this helps prevent buildup of oil, grease, or product fragments that could cause imbalance or hinder rotation. For optimal sanitation, perform a final rinse with deionized water and allow components to air dry completely before reassembly.

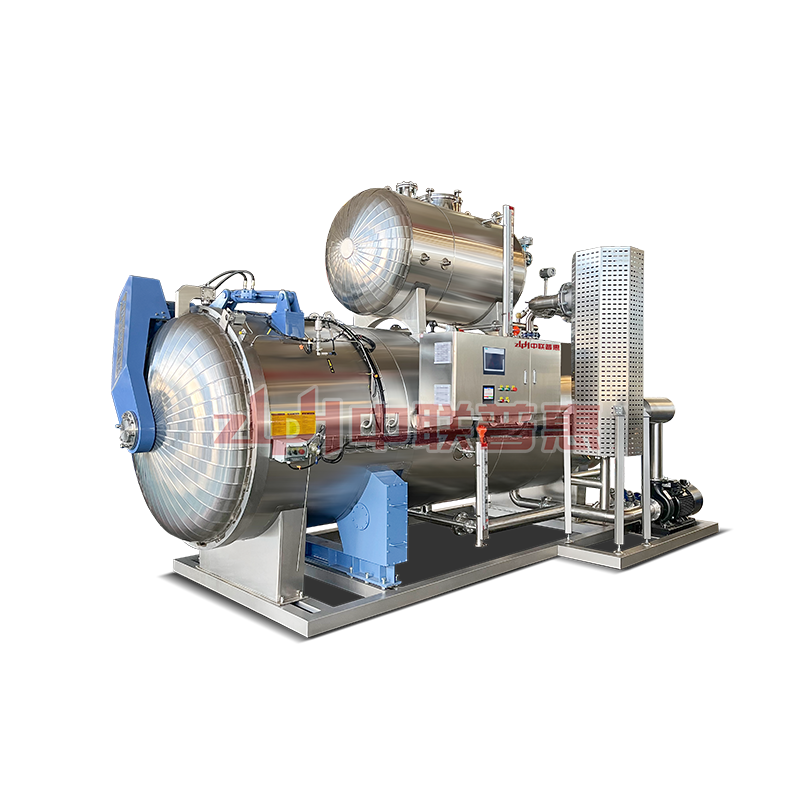

retort autoclave

rotary sterilizer

rotary retort machine

rotary retort autoclave

4

Preventing Corrosion and Component Fatigue

Because the rotary retort autoclave operates under high pressure and temperature, condensation and chemical exposure can accelerate corrosion. Regularly applying a light protective coating to metallic parts—such as shafts and couplings—can effectively minimize rust. Periodic ultrasonic inspection can also detect microcracks or fatigue in mechanical joints before they develop into costly breakdowns.

In addition, operators should monitor the sealing performance of the autoclave retort sterilizer door gaskets. Damaged seals can cause steam leaks, affecting pressure stability and rotation accuracy. Always replace worn gaskets promptly to maintain system integrity and efficiency.

5

Calibration and Performance Testing

Every rotary sterilizer requires scheduled calibration of its rotation speed and torque control. Deviations in rotation speed can directly affect product quality, especially for viscous foods. Testing should be done at least once every three months, using manufacturer-specified procedures to verify that the rotary retort machine meets required performance standards.

Furthermore, temperature sensors and control valves inside the retort autoclave should be checked for accuracy. Proper synchronization between rotation and temperature ensures uniform sterilization and prevents overheating or underprocessing.

6

Benefits of a Consistent Maintenance Routine

Regular cleaning and maintenance of the rotating system and basket drive in a rotary retort autoclave bring several long-term advantages:

Improved equipment reliability – Reduces mechanical failure and downtime.

Consistent product quality – Ensures uniform heat distribution and sterilization.

Extended lifespan – Minimizes wear on critical components.

Lower operational costs – Prevents expensive repairs and unplanned maintenance.

Enhanced safety – Maintains stable pressure and rotation under demanding conditions.

autoclave retort sterilizer

retort autoclave

rotary retort autoclave

Proper maintenance and cleaning routines are essential for the long-term performance of your retort autoclave. The rotating system and basket drive of a rotary sterilizer or rotary retort autoclave require careful attention to lubrication, inspection, and cleaning to operate at peak efficiency. By following a structured maintenance plan and addressing wear promptly, operators can ensure that every batch processed in their autoclave retort sterilizer achieves optimal sterilization results with maximum reliability.

ZLPH has been breaking the barriers of food technology for a long time. Through our unparalleled persistence and high standards of product quality, we have provided high-level, advanced technology and reliable solutions to all our industry partners, which has also indirectly consolidated This reinforces our position as a leader in the food machinery industry and a trustworthy supplier.