Why Is Rotation (Rotary Design) Important for Processing High-Viscosity Foods Like Instant Bird’s Nest?

In modern food manufacturing, especially when dealing with high-value, high-viscosity products such as instant bird’s nest, achieving perfect sterilization while maintaining product texture and nutrition is a delicate balance. Traditional static sterilization systems can fall short when it comes to even heat distribution and consistent product quality. That’s where the rotary design of a retort machine becomes critical. The introduction of rotation in a retort autoclave not only improves sterilization efficiency but also ensures that every container receives uniform heat treatment—an essential factor in processing thick or semi-liquid foods like bird’s nest.

Understanding the Role of Rotation in a Retort Machine

A retort machine is a specialized vessel designed to sterilize packaged food using high temperature steam or hot water under pressure. The process eliminates harmful microorganisms and extends shelf life. However, in high-viscosity foods—like instant bird’s nest concentrate, sauces, or porridges—the density of the product can cause uneven heat transfer. In a static food retort machine, the upper layers may become overheated while the inner contents remain underprocessed.

To solve this, ZLPH use a rotary retort autoclave. This equipment gently rotates the containers during sterilization, continuously mixing the product and ensuring even temperature distribution. The rotation motion eliminates cold spots, reduces sterilization time, and preserves delicate nutrients.

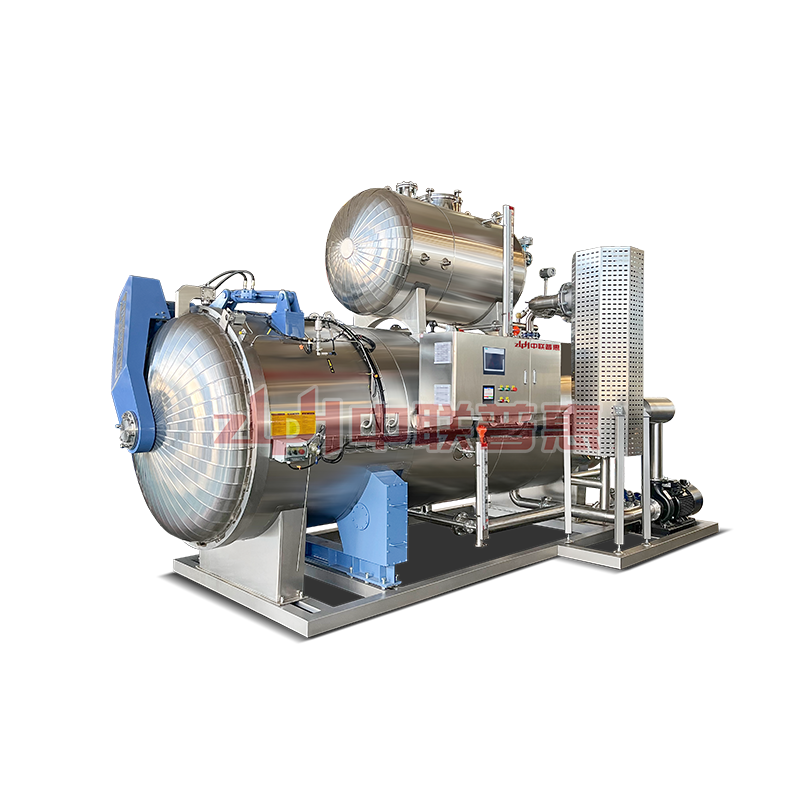

retort machine

retort autoclave

food retort machine

How the Rotary Retort Autoclave Improves Sterilization

The retort autoclave operates with a rotating basket system. As the containers rotate inside the chamber, high temperature steam or circulating hot water flows evenly across every surface. This motion prevents sedimentation, reduces temperature differences inside the containers, and ensures that even the most viscous products are uniformly treated.

In comparison, a non-rotary sterilization retort machine relies solely on thermal conduction, which can be slow and inconsistent for thick materials. Rotation enhances convection within the container, allowing faster heat penetration. This means less processing time, better texture retention, and more efficient energy use.

Benefits of Rotation for High-Viscosity Foods

For foods like instant bird’s nest, which naturally contain a gelatinous texture, rotation is not just an advantage—it’s a necessity. The rotary retort machine provides several key benefits:

Uniform Heat Distribution: By rotating containers continuously, the food retort machine ensures every part of the product is heated evenly, eliminating under- or over-processing.

Shorter Processing Time: The movement allows the retort autoclave to reach sterilization temperatures more quickly, minimizing nutrient loss.

Preservation of Texture: Rotation prevents clumping and sticking, maintaining the smooth, delicate texture that bird’s nest consumers expect.

Reduced Thermal Stress: The gentle agitation helps protect the packaging and prevents deformation during high temperature steam sterilization.

Improved Product Consistency: Every batch achieves the same quality level, essential for maintaining brand reputation.

high temperature steam

sterilization retort machine

The Science Behind the Process

When processing high-viscosity foods, heat transfer mainly occurs through conduction and convection. In a sterilization retort machine, the rotary motion enhances natural convection by constantly changing the product’s position relative to the heat source. This mechanical movement ensures that areas which might otherwise be insulated by thick material receive sufficient heat.

Additionally, the retort autoclave’s high temperature steam helps achieve uniform internal pressure, ensuring that heat penetrates deeply into dense mixtures without damaging the food or packaging. This controlled environment allows for precise sterilization while preserving taste, aroma, and nutritional value.

In the world of high-viscosity food processing, the rotary retort autoclave represents a significant technological advancement. By combining rotational motion, high temperature steam, and precise control, this specialized retort machine ensures even heat distribution, faster processing times, and superior product quality. For manufacturers of instant bird’s nest, soups, or other thick foods, the rotary food retort machine provides an efficient and reliable solution that meets the highest standards of food safety and taste.

ZLPH has been breaking the barriers of food technology for a long time. Through our unparalleled persistence and high standards of product quality, we have provided high-level, advanced technology and reliable solutions to all our industry partners, which has also indirectly consolidated This reinforces our position as a leader in the food machinery industry and a trustworthy supplier.