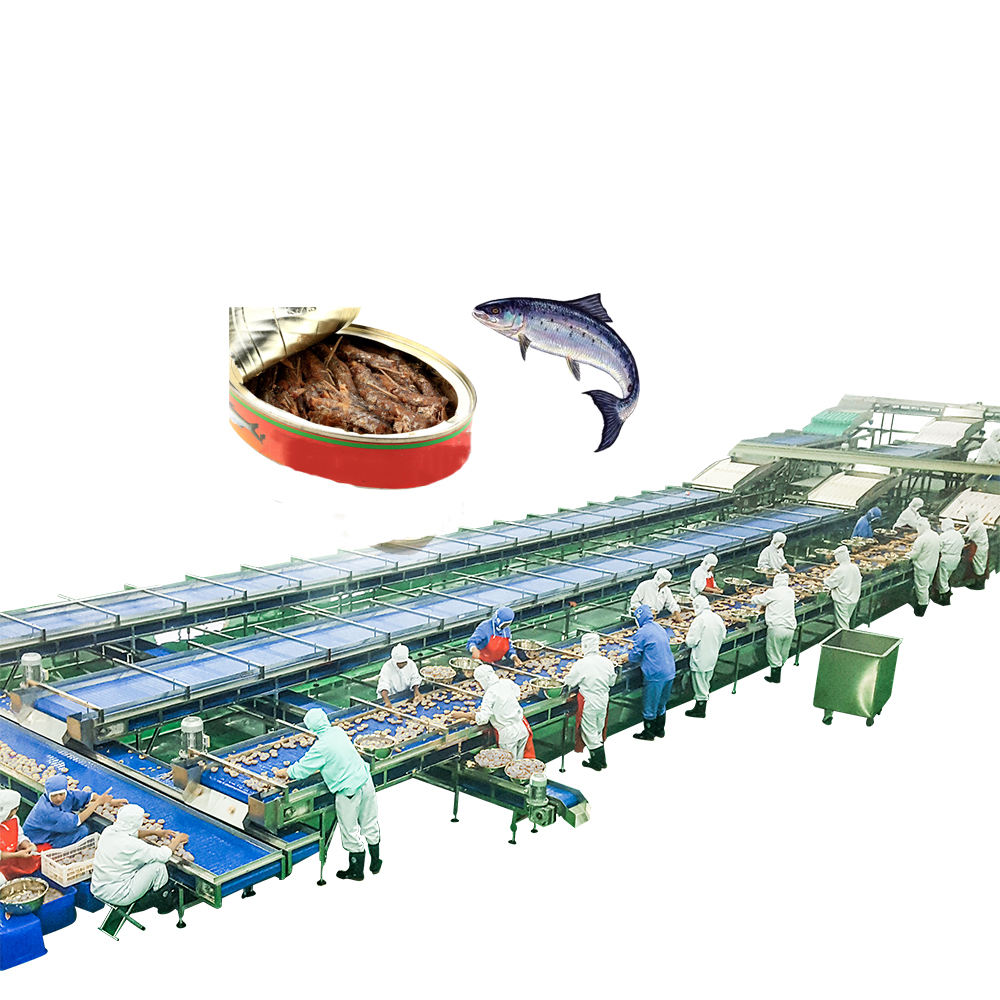

A leading Indonesian sardine processing factory supplying major global retailers under private-label agreements.

The client faced mounting pressure to reduce production costs while simultaneously improving product consistency and extending shelf life for international export. Their existing sterilization line suffered from uneven heat distribution, resulting in:

High variance in texture quality (15% of batches showing mushy sardines)

Energy consumption 40% above industry benchmarks

Limited flexibility in can size formats

Frequent manual adjustments causing production delays

Solution: ZLPH MACHINERY’s Integrated Retort System

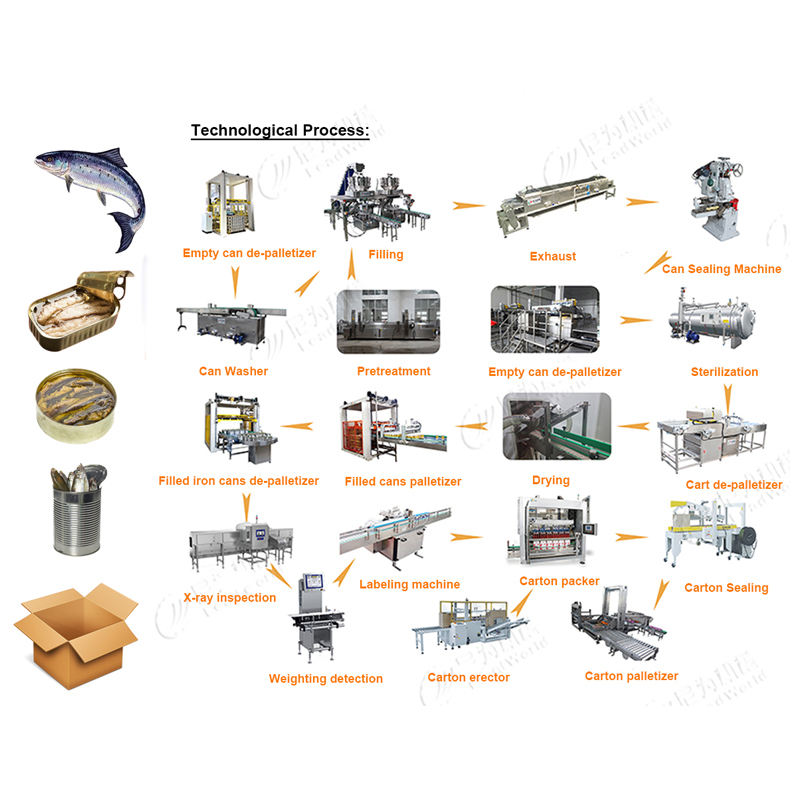

After thorough analysis, we installed a complete processing line featuring:

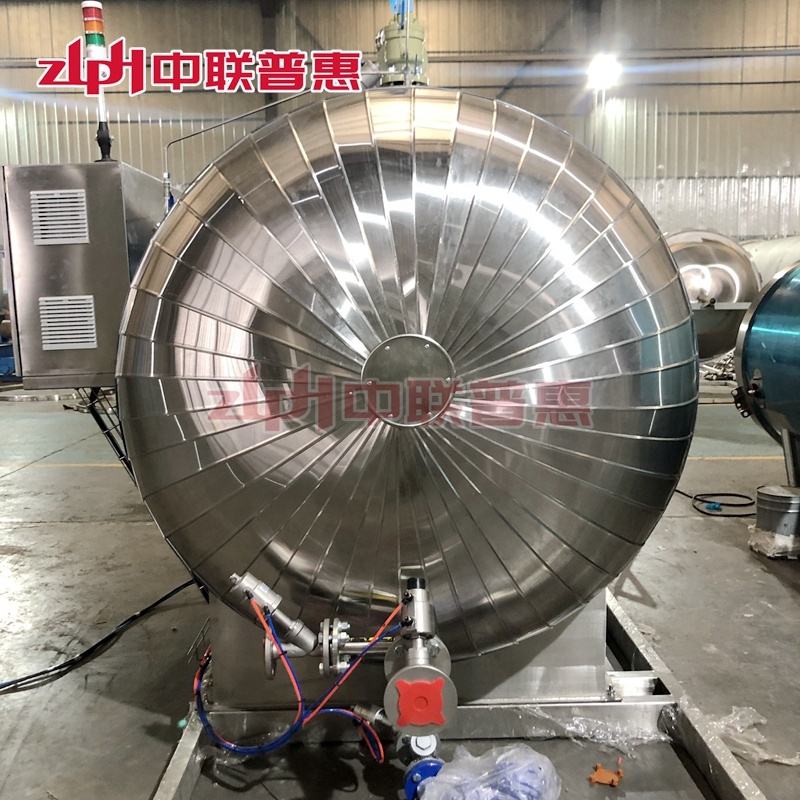

ZLPH High-Efficiency Retort Autoclave

Our flagship autoclave retort sterilizer employs dynamic pressure modulation specifically calibrated for oily fish products. The system’s multi-zone temperature control eliminated cold spots that previously caused inconsistent sterilization.

Automated Can Handling System

The integrated retort canning machine synchronizes with the retort packaging machine to maintain precise headspace control during filling and sealing—critical for maintaining sardine integrity during thermal processing.

Intelligent Process Management

The central retort machine control system automatically adjusts sterilization parameters based on real-time oil content analysis and can size detection, ensuring optimal F-value achievement without over-processing.

Implementation & Results:

Within 90 days of installation, the client achieved measurable improvements:

Energy consumption decreased by 38% through heat-recovery technology in the retort autoclave

Water usage reduced by 52% via closed-loop cooling system

Labor costs lowered by 60% through fully automated operation

Product loss from over-processing eliminated entirely

Texture consistency improved to 99.3% compliance rate

Omega-3 fatty acid retention increased from 78% to 94%

Shelf life extended from 18 to 36 months

Zero microbiological incidents across 500+ production batches

OEM Partnership Benefits:

As the client’s designated OEM partner, ZLPH MACHINERY provided:

Customized retort packaging machine configurations for their specific can dimensions

On-site technician training and 24/7 remote monitoring

Quarterly performance optimization reports

Spare parts inventory management program

Technical Superiority Demonstrated:

The autoclave retort sterilizer consistently maintained temperature uniformity within ±0.7°C, far exceeding the industry standard of ±2.5°C. This precision, combined with the reliability of our retort canning machine interface, enabled the client to expand production capacity by 45% without additional floor space.

“ZLPH’s retort machine system didn’t just upgrade our equipment—it transformed our business model. We’ve reduced operational costs by $2.8 million annually while securing contracts with three new European retailers who specifically praised our product consistency. Their OEM partnership approach ensured seamless integration with our existing infrastructure.”

— Production Director, Indonesian Sardine Cannery

Why This Matters for Your Operation:

This case demonstrates how strategic investment in ZLPH MACHINERY’s retort autoclave technology delivers:

Quantifiable ROI within 14-18 months

Enhanced competitive advantage in private-label markets

Uncompromising food safety assurance

Scalable production capabilities

Ready to Achieve Similar Results?

Contact ZLPH MACHINERY today for a free production efficiency analysis. Our engineers will develop a customized proposal showing exactly how our retort machine systems can optimize your sardine canning operations.