For generations, traditional Thai bird's nest enterprises relied on sun-drying and basic thermal methods for preservation. While these methods honored artisanal heritage, they presented inconsistencies in microbial control and product stability. As global food safety standards evolved, one forward-thinking Thai enterprise embarked on a technological transformation, seeking to bridge traditional wisdom with modern Bird's Nest Sterilization science.

Technology Transition Journey

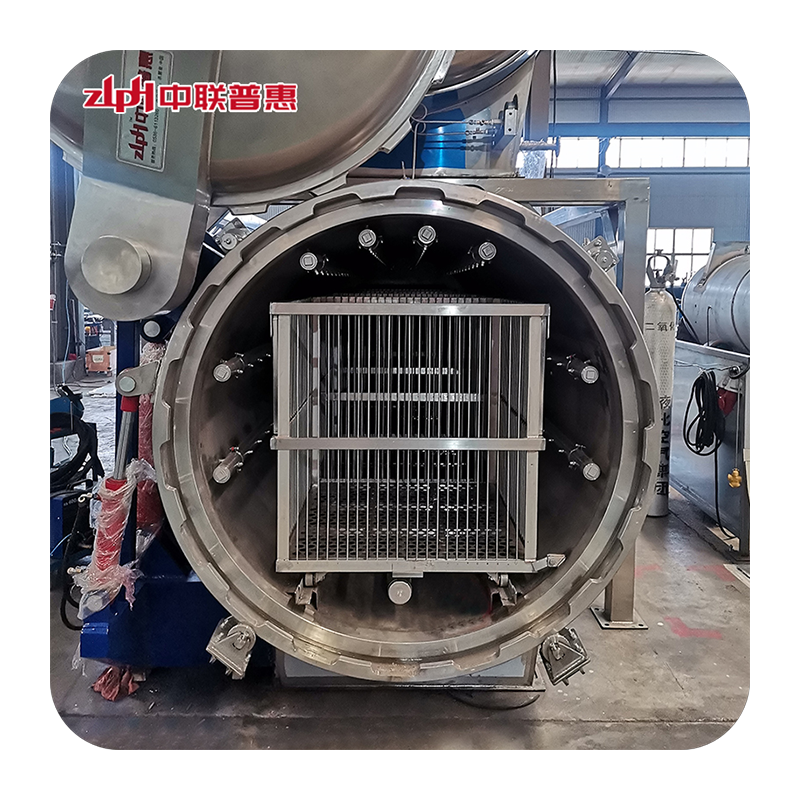

The enterprise's modernization centered on implementing advanced retort sterilisation systems while preserving the essence of traditional quality. After evaluating multiple solutions, they selected ZLPH MACHINERY's integrated technology platform, recognizing its ability to deliver precise control essential for delicate bird's nest processing. The implementation began with a phased approach, introducing automated steam retort machine systems alongside existing traditional methods to ensure seamless transition.

Modernization Implementation

The transformation involved three key phases:

Technology Integration: Installation of computer-controlled Retort Machine systems with precision temperature and pressure regulation

Process Optimization: Development of customized sterilization protocols balancing traditional quality parameters with modern safety requirements

Quality System Enhancement: Implementation of comprehensive monitoring and documentation systems for complete process transparency

Technical Achievements

The modernized operation achieved significant improvements:

Consistent microbial reduction exceeding 99.99% through optimized Bird's Nest Sterilization cycles

Enhanced product stability with shelf life extended from 6 to 24 months

Preservation of traditional texture and appearance characteristics valued by discerning consumers

40% reduction in processing time compared to traditional methods

ZLPH MACHINERY's Partnership Role

Our company provided comprehensive support throughout this transformation:

Customized Technology Solutions: Engineered Retort Autoclave systems specifically configured for traditional-to-modern transition requirements

Process Validation Services: Conducted extensive testing to establish optimal retort sterilisation parameters preserving traditional quality markers

Cultural-Technical Integration: Developed implementation approaches respecting traditional knowledge while introducing modern scientific methods

Continuous Support: Established ongoing technical partnership for system optimization and staff development

Operational Transformation

The modernization impacted multiple operational areas:

Quality Consistency: Advanced control systems eliminated batch-to-battle variations common in traditional methods

Safety Assurance: Automated steam retort machine operations provided documented compliance with international food safety standards

Production Scalability: Modern systems enabled increased production capacity while maintaining quality standards

Market Expansion: Enhanced safety documentation and extended shelf life opened new export market opportunities

Cultural Preservation Aspects

A unique aspect of this transformation was maintaining traditional quality characteristics. ZLPH engineers worked closely with the enterprise's master processors to identify key quality markers that needed preservation. The resulting Bird's Nest Sterilization protocols specifically addressed these traditional parameters while achieving modern safety standards.

The technological transformation delivered measurable business benefits:

35% increase in production efficiency

60% reduction in product returns due to quality inconsistencies

Access to premium international markets with stringent safety requirements

Enhanced brand reputation through demonstrable quality improvements

The enterprise continues its technological evolution with plans for:

Further automation of Retort Machine operations

Implementation of advanced quality monitoring systems

Expansion of processing capacity utilizing proven technology platformDevelopment of specialized product lines leveraging technological capabilities

This case demonstrates how traditional food processing enterprises can successfully integrate modern technology while preserving cultural heritage. The Thai enterprise's experience provides a valuable model for similar businesses facing the challenge of meeting modern safety standards without sacrificing traditional quality characteristics.

Key success factors identified through this transformation include:

Phased implementation allowing gradual technology adoption

Respect for traditional knowledge in technology configuration

Comprehensive staff training supporting technology acceptance

Continuous partnership with technology providers for ongoing optimization