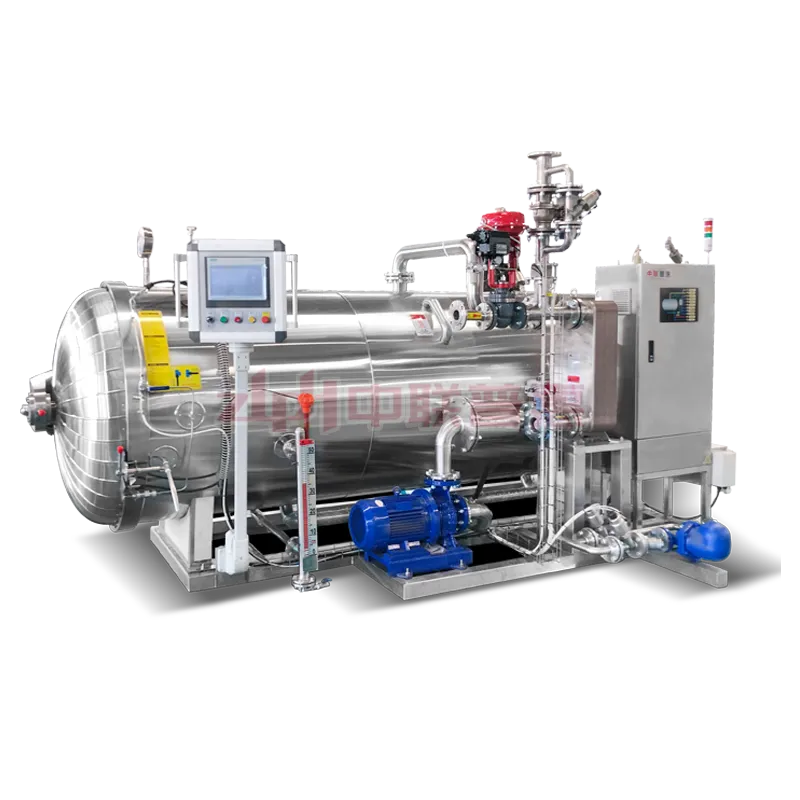

Canned luncheon meat, a beloved addition to hotpot meals and spicy dishes, has secured its place on dining tables worldwide for decades. But behind its convenience and flavor lies a critical process that guarantees its safety and longevity: high-temperature Commercial Sterilization. Traditionally, canned products like luncheon meat are processed using steam-air methods in specialized equipment. This involves heating the cans to precise temperatures and holding them there long enough to eliminate harmful bacteria, botulinum spores, and other microorganisms—ensuring the product meets stringent Commercial Sterilization standards and remains shelf-stable for extended periods.

2026-01-02

More