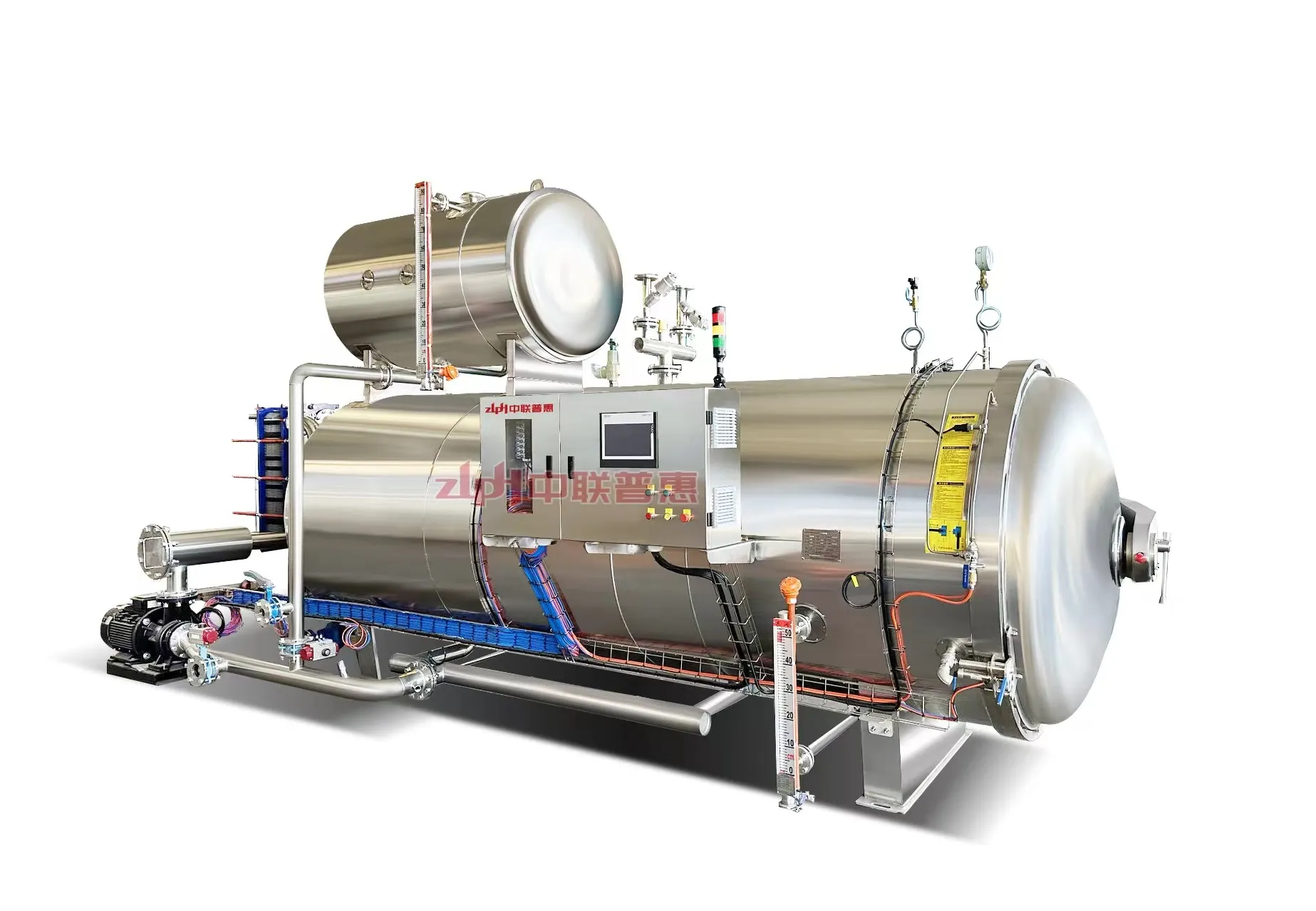

In the premium food sector, Bird's Nest Sterilization stands as a critical process to ensure safety, preserve nutrients, and extend shelf life without compromising quality. As a leading innovator in thermal processing technology, we specialize in designing and manufacturing high-performance retort machines, including specialized retort autoclaves for delicate products like bird’s nest. Our food retort machines are engineered to meet the strictest sterilization standards while maintaining the integrity and nutritional value of this high-value commodity.

2026-01-05

More