Boxed Rice Intelligent Sterilization Production Line Gains Recognition

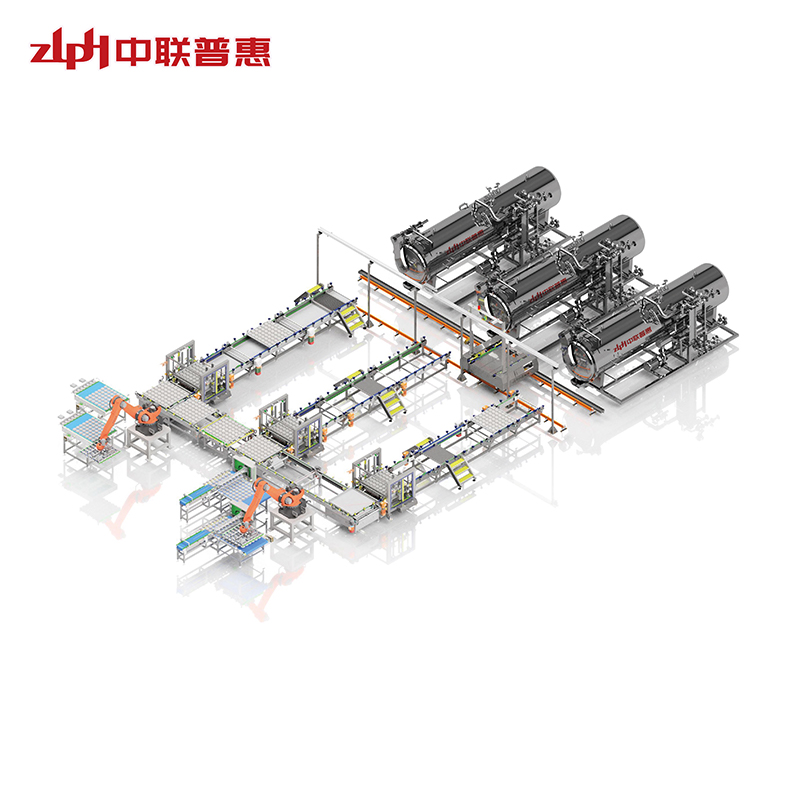

This boxed rice intelligent sterilization production line, tailor-made for customers, is an efficient production line integrating multiple intelligent technologies. As a production line specializing in boxed food processing, it has attracted much attention in the food processing field due to its highly automated operation mode, and has been adopted by Yili Group, becoming an important choice for many food enterprises to upgrade their production equipment.

The production line focuses on the sterilization needs of boxed and cup-shaped food. The sterilization function runs through the whole process. From the moment the product enters the production line, the preparation work related to sterilization is initiated. It integrates multiple intelligent technologies to build an efficient and precise full-process sterilization solution. Among them, the robot is an important equipment of the production line, and the robot loading and unloading system is a major highlight. The robot is precisely controlled by a preset program, operates according to the set parameters and trajectory, and can quickly adapt to the placement angle and position of boxed rice. Through the flexible operation of the mechanical arm, the boxed rice is arranged in order and accurately placed into the sterilization tray. The number of loaded boxes per tray and the arrangement spacing are pre-calculated and set by the program. The robot loading process is efficient with minimal error, capable of completing the loading of thousands of boxes per hour. After sterilization, the robot can automatically and orderly unload the products from the tray and transport them to the next link according to the set trajectory. The participation of the robot makes the whole process free of manual intervention, greatly improving the continuity and stability of production.

The automation of the production line is reflected in every link. From product transportation to the adjustment of sterilization parameters, all are automatically completed by the system. The equipped RGV intelligent trolley undertakes the important task of transporting products before and after sterilization, and its automatic operation ensures the smooth flow of the process. The RGV intelligent trolley is equipped with a high-precision navigation system, which can shuttle accurately in complex production environments. It can automatically send the tray loaded with boxed rice into the retort according to the preset program. During the process of entering and exiting the retort, it can seamlessly dock with the door of the retort to avoid shaking or falling of products during transportation. After the completion of the sterilization process, the RGV intelligent trolley will accurately take it out of the retort, realizing the full automation of the in and out of the retort, with short time consumption and high efficiency. As the core equipment, the retort is the key to realize the sterilization function. It can automatically adjust the sterilization temperature, time, pressure and other parameters according to the characteristics of boxed rice, ensuring that while killing microorganisms, the taste and quality of rice are retained to the greatest extent. The sterilization effect is remarkable, and the shelf life of the products processed by the retort can be effectively extended.

From the orderly loading of products, the automatic in and out of the retort by the RGV intelligent trolley, to the precise sterilization of the retort, and then to the automatic unloading of the robot, the entire production line forms a closed-loop automated system, perfectly realizing the intelligent operation of the boxed rice sterilization process, and once again highlighting the automation advantages of the production line. The production line is also equipped with an intelligent monitoring system, which can monitor the operation status of each link in real time. In case of any abnormality, it will immediately issue an alarm and automatically take emergency measures to ensure the stable operation of the production line.

It is worth mentioning that this advanced production line not only meets the production needs of customized customers, but also its reliable performance and efficient operation mode have been favored by Yili Group. After introducing this production line, Yili Group has increased the production efficiency of boxed food by more than 30%, and the sterilization qualification rate has reached 100%, becoming an important part of the group's food processing link. It fully demonstrates the benchmark value of this production line in the field of sterilization of boxed and cup-shaped food, and also further expands the influence of the production line. More and more food enterprises have begun to pay attention to and introduce this efficient intelligent sterilization production line.

If you’re interested in learning more about our ZLPH Retort or exploring potential cooperation opportunities, feel free to reach out to us via email at saleshayley@zlphretort.com or connect with us on WhatsApp at +86 15315263754.