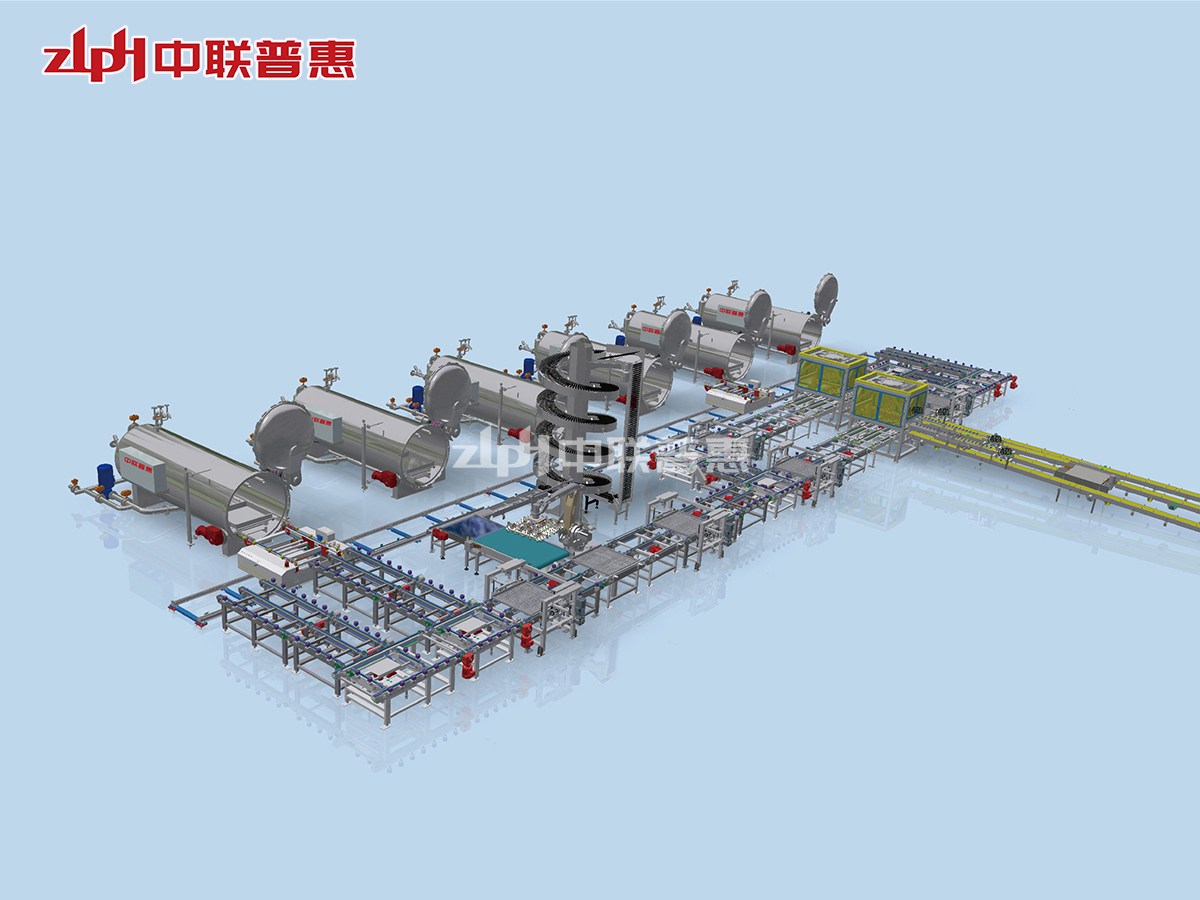

Intelligent sterilization line put into operation, demonstrating overall line strength

A groundbreaking milestone has been achieved in China’s food processing industry - the first intelligent unmanned gelidium herb sterilization production line, a highly intelligent solution tailor-made by our company, has been officially put into operation at Shenghetang. This intelligent production line not only fills the technical gap in the field of intelligent sterilization in China’s gelidium herb industry but also showcases our company’s top-tier strength in providing overall sterilization solutions for bagged and cup-shaped food and beverages through its fully automated and intelligent design.

As a leading enterprise specializing in food sterilization equipment and complete line design, we have always adhered to the core values of “customization, intelligence, and high efficiency”, providing one-stop services from individual sterilization equipment to complete intelligent production lines for various food enterprises. The sterilization production line built for Shenghetang is a benchmark intelligent project customized according to the characteristics of gelidium herb products. It is an intelligent system that can accurately adapt to neatly arranged boxed, penguin-packaged, and bagged gelidium herb products, realizing the fully automated and intelligent operation from product loading tray, stacked tray conveying to sterilization and tray unloading, thus significantly improving production efficiency and sterilization stability.

In this intelligent production line, the retort, as the core sterilization equipment, has excellent sterilization performance. This advanced retort adopts a precise intelligent temperature control system, which can automatically and intelligently adjust the sterilization temperature, pressure, and time according to the characteristics of gelidium herb products in different packaging forms, ensuring that while effectively performing sterilization to kill bacteria, the taste and nutritional components of gelidium herb are retained to the greatest extent. At the same time, the retort is equipped with a highly intelligent monitoring module, which can feedback the equipment operation status in real-time, realize intelligent fault early warning and remote diagnosis, and provide a solid guarantee for the stable operation of the intelligent production line.

In addition to the core sterilization equipment, the intelligent design of the entire sterilization production line is also a prominent highlight. The production line introduces an intelligent robot orderly tray-loading system. Through the intelligent collaboration of high-precision visual recognition and robotic arms, boxed, penguin-packaged, and bagged gelidium herb products are accurately and automatically arranged and loaded into sterilization trays. The tray-loading efficiency is more than 3 times that of traditional manual work, and the error rate is controlled within 0.1%. The stacked tray conveying section adopts an intelligent logistics scheduling system, which can automatically and intelligently complete stacking, buffering, and conveying by real-time monitoring of the conveying status through sensors, ensuring precise matching with the feeding rhythm of the retort.

From the design of a single high-performance retort to a complete intelligent sterilization production line, we have always been customer-oriented, integrating technologies from multiple fields such as mechanical design, automatic control, and food technology to create an integrated “equipment-process-management” intelligent solution. The successful commissioning of Shenghetang’s intelligent unmanned sterilization production line not only confirms our strong ability in complete line design but also provides a replicable intelligent model for the intelligent upgrading of bagged and cup-shaped food and beverage enterprises.

In the future, our company will continue to deepen its presence in the field of food sterilization, continuously invest in complete line design and intelligent equipment research and development, provide more efficient, intelligent, and reliable sterilization solutions for more food enterprises, and help the industry move towards a new era of intelligent and automated production.