Sterilization mode of autoclave: a double leap in efficiency and effect

In today's food processing industry, especially the meat processing industry, the efficiency and effect of the sterilization process play a vital role in the survival and development of enterprises. The high-pressure and extremely fast sterilization mode of the autoclave has become a key force in promoting the progress of the industry with its unique advantages, achieving a double leap in efficiency and effect.

1. Unique mechanism of high-pressure rapid sterilization mode

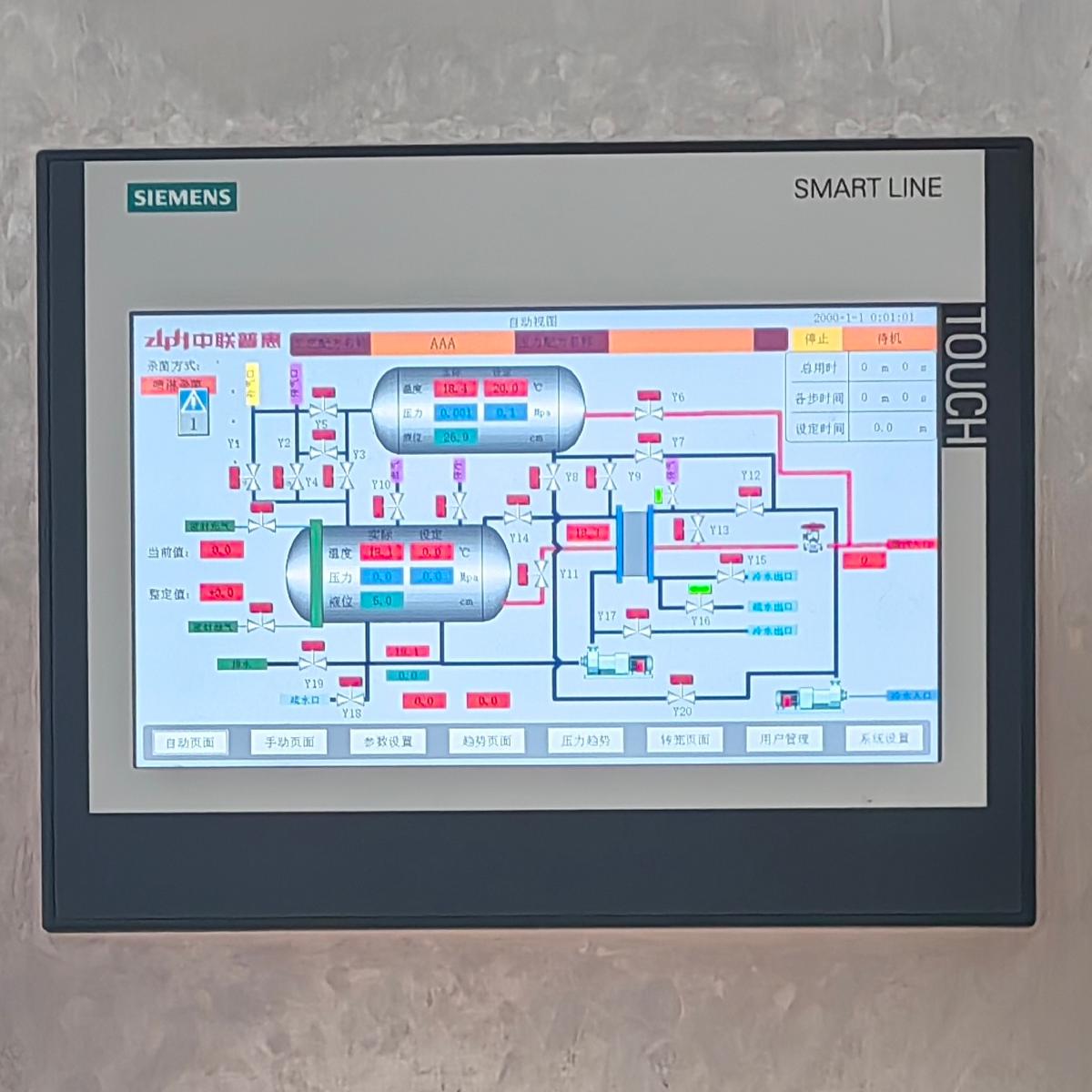

The high-pressure and rapid sterilization mode of the autoclave has a special mechanism for pressure building and release. During operation, the equipment can quickly start the pressure building program, and with the help of an advanced pressurization system, the pressure in the autoclave can rise sharply in a short period of time. For example, it can increase the pressure to a specific high-pressure state within a few minutes, and this pressure value is often difficult to achieve with traditional sterilization methods. This high-pressure environment will form a strong physical pressure on the cell structure of microorganisms, change its internal physiological and biochemical state, and cause the cell membrane, cell wall and other key structures of the microorganisms to be destroyed, thereby affecting their normal metabolism and survival ability.

The pressure release process is also critical and unique. Rather than simply reducing the pressure, the pressure is released at a specific rate and rhythm through precise valve control and intelligent program settings. This orderly pressure release, combined with the previous high pressure effect, forms a synergistic effect, allowing the entire sterilization process to be completed in a very short time, usually only 1/3 of the conventional sterilization time. For example, conventional sterilization methods may take 90 minutes to achieve the desired sterilization effect, while the high-pressure extreme-speed sterilization mode only takes about 30 minutes to complete the same high-quality sterilization task.

2. Impact on the production cycle and capacity of meat processing enterprises

In terms of the production cycle, the traditional sterilization method in the past took a long time, causing the meat products to stay in the sterilization process for a long time, which in turn slowed down the operation of the entire production chain. However, after the introduction of high-pressure ultra-fast sterilization mode, the "time bottleneck" originally caused by the sterilization process has been effectively broken due to the significant shortening of sterilization time. For example, the time it takes for a batch of meat products to enter the sterilization process and exit the sterilization kettle is greatly reduced, allowing subsequent packaging, quality inspection and other links to be carried out faster, and the entire production cycle can be significantly compressed, allowing enterprises to The production process becomes more compact and efficient, and products can be brought to market faster.

Without adding additional production equipment or manpower, the number of meat product batches that can be processed per unit time has increased significantly due to the time saved in the sterilization process. According to actual application data, after adopting this high-pressure and extremely fast sterilization mode, the production capacity of meat processing companies can be increased by more than 30%.

3. Ensure thorough sterilization and food safety

Although the high-pressure and rapid sterilization mode focuses on improving efficiency, it does not compromise on the thoroughness of sterilization, and always maintains high standards of quality control, which fully meets the stringent requirements of international food safety.

In meat products, there are often various harmful microorganisms lurking. The high-pressure and rapid sterilization mode, with its strong pressure and special sterilization mechanism, can form an all-round "strike" against these microorganisms. Whether it is the nutrient body of the microorganism or the spore structure with tenacious resistance, it is difficult to survive in this mode, thus ensuring that meat products meet extremely high hygiene and safety standards from the source of processing, so that consumers can eat with confidence.