PE Bottle Product Robot Loading and Unloading Sterilization Production Line: Intelligent Damage Prevention, Strictly Guarding Food Safety

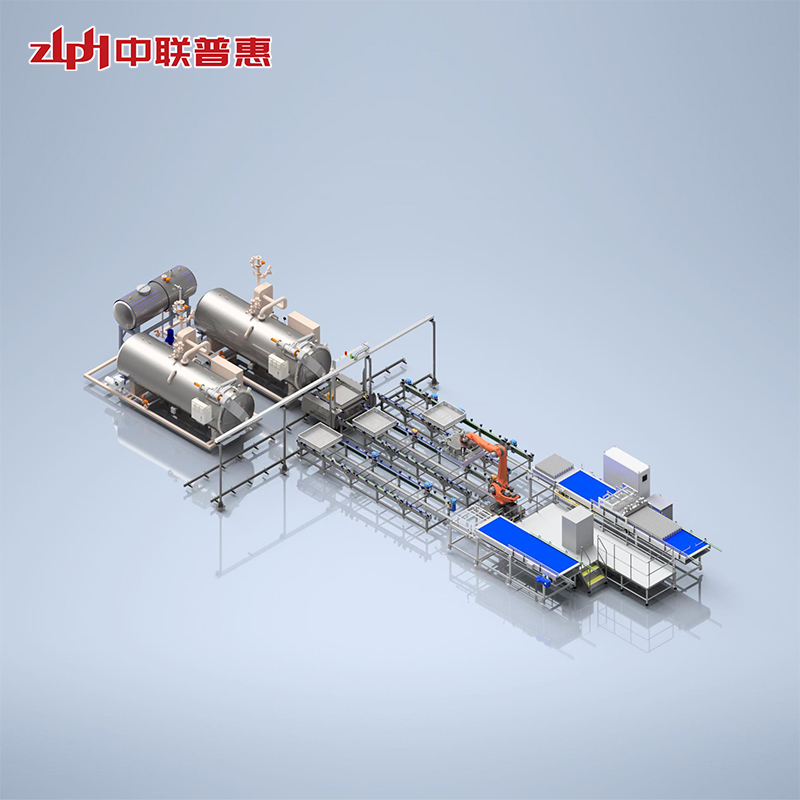

In the food and beverage industry, PE material bottled products are widely used due to their strong corrosion resistance and low cost. However, the mechanical loading and unloading methods in traditional sterilization processes are prone to cause bottle body extrusion deformation, label wear, and the risk of uneven sterilization caused by bottle tipping. Aiming at the special hygiene requirements of the food and beverage industry, ZLPH has launched a food-grade PE bottle robot loading and unloading sterilization production line. Through the innovation of robot flexible gripping technology and food-grade fixtures, it realizes fine-process control from loading to unloading, helping enterprises improve product quality and production efficiency.

I. Industry-Specific Pain Points and Solutions in Food and Beverage

Core Challenges

High Demand for Bottle Protection

Most PE bottles for food and beverages use labeling or hot stamping processes. Traditional mechanical grippers are prone to scratching labels during loading and unloading (with a damage rate of 1.2%), affecting product appearance qualification rates.

Sterilization Risks Caused by Bottle Tipping

During manual or traditional mechanical loading, skewed bottles lead to uneven heat transfer in retorts, increasing the risk of microbial overgrowth.

Strict Food-Grade Hygiene Requirements

Loading and unloading equipment must comply with standards such as FDA and GB 14881. Traditional metal fixtures are prone to corrosion and difficult to clean, hiding dirt.

ZLPH Innovative Solutions

Robot + Food-Grade Four-Side Clamping Fixture: Zero-Damage Handling

Flexible Gripping Technology

Using six-axis food-grade robots (surface treated with FDA-certified coatings) equipped with Four-sided clamp silicone fixtures, air pressure sensors dynamically adjust gripping force to ensure uniform force on PE bottles during handling. For example, for 500ml bottled beverages, the fixture precisely matches the bottle body curvature to avoid cracks at the bottleneck due to extrusion.

Anti-Tipping Four-Side Clamping Technology

The fixture adopts a Four-sided clamp structure, uniformly fitting the bottle body through food-grade silicone pads (contact area increased to 80% of the bottle circumference), with air pressure sensors real-time calibrating gripping force. Combined with robot motion trajectory optimization, the bottle body remains stable throughout the gripping and loading process, reducing the tipping rate from the industry average of 3% to below 0.1%.

Sterilization Tray Design: Food-Grade High-Efficiency Sterilization

Open Tray Structure

Directly stack PE bottles on 304 stainless steel sterilization trays with built-in flow guide grooves to ensure uniform penetration of steam/water during sterilization, improving heat distribution uniformity to 98.5% (traditional cage structures only achieve 85%).

Compact Hygienic Layout

The loading and unloading area is unobstructed, using a stainless steel 304 frame + rounded corner design with no hygienic dead spots. 304 stainless steel sterilization trays can be quickly disassembled and connected to a CIP online cleaning system, reducing single cleaning time to 15 minutes to meet the daily multi-cycle cleaning needs of food enterprises.

Full-Process Automation: Dual Improvement in Efficiency and Safety

High-Speed Precision Operation

Single robot can handle 10,000-15,000 bottles per hour (adjustable by bottle type), an 8-10x efficiency improvement over manual loading/unloading. Taking 500ml bottled beverages as an example, the production line completes 250 bottles per minute, adapting to high-speed retorts (6 batches per hour).

Food-Grade Data Traceability

The system automatically records batch-specific loading/unloading times, sterilization temperatures (accuracy ±0.3°C), pressure curves, and other data, storing them in a food-grade MES system to generate HACCP-compliant quality inspection reports for regulatory traceability.

II. Process Details of Sterilization Section

Automatic Loading: Precise Positioning for Uniform Sterilization

Bottle Orientation Recognition and Tray Loading Planning

After gripping PE bottles, robots use top visual cameras to detect cap orientation (e.g., tamper-evident ring direction), ensuring all bottles are vertically stacked on 304 stainless steel sterilization trays with row/column spacing controlled at ±1.5mm. The bottle mouth upward deviation is <2° to avoid incomplete sterilization due to content sedimentation.

Anti-Collision Buffer Design

304 stainless steel sterilization trays are edged with food-grade silicone anti-collision strips. Robots use a "soft landing" mode (descent speed ≤50mm/s) when placing bottles to reduce impact damage between the bottle and tray.

Intelligent Sterilization: Food-Grade Sterilization Process Optimization

Seamless retort Docking

Robots achieve ±2mm positioning accuracy to smoothly push 304 stainless steel sterilization trays into spray retorts. For low-acid foods, high-temperature and high-pressure sterilization programs (121°C/30min) are automatically matched to ensure pathogen elimination.

Thermal Distribution Simulation Verification

The system's built-in sterilization process simulation module previews heat penetration curves by inputting bottle type and content characteristics, optimizing loading density and sterilization time to avoid flavor loss from over-sterilization (e.g., vitamin C retention rate increased to 92%).

Robot Precision Unloading: Food-Grade Zero-Damage Operation

After sterilization, robots directly grip PE bottles through fixtures, removing them from 304 stainless steel sterilization trays and placing them on conveyor lines at a stable speed of ≤50mm/s, avoiding bottle impact from traditional flipping or vibration unloading. The entire process uses visual guidance for precise gripping, reducing liquid sloshing by 90% and bottle damage rate to as low as 0.05%. Unloaded 304 stainless steel sterilization trays are centrally collected by robots to designated areas.

III. Food and Beverage Industry Application Case

Case: Production Line Upgrade for a Bottled Beverage Enterprise

Customer Needs

Solve label damage (original damage rate 1.8%) and bottle tipping (tipping rate 2.5%) during sterilization of 500ml PE bottled beverages, while increasing production capacity to meet peak season demands.

ZLPH Solution

Deploy 2 food-grade robots + 4 spray retorts linked production line, using silicone fixtures and 304 stainless steel sterilization trays with supporting CIP cleaning systems.

Implementation Results

Quality Improvement: Label damage rate reduced to 0.2%, tipping rate <0.1%, microbial overgrowth rate reduced from 0.5% to 0.05%;

Efficiency Improvement: Single-shift capacity increased from 120,000 to 300,000 bottles, labor cost reduced by 5 personnel per line;

Hygiene Compliance: Passed FDA, GB 14881 and other certification audits, cleaning efficiency improved by 60%, meeting daily three-shift continuous production needs.

IV. Food Industry-Specific Technology Upgrade Directions

Low-Carbon Energy-Saving Solutions

Introduce servo motor energy-saving robots (energy consumption reduced by 35% compared to traditional models) and optimize retort energy recovery systems to reduce steam consumption by 20%, aligning with food enterprises' green production goals.

For detailed configurations of this production line in subdivisions such as bottled beverages, please contact ZLPH's Marketing Department for customized solutions.

If you're interested in learning more about our ZLPH Retort or exploring potential cooperation opportunities, feel free to reach out to us via email at saleshayley@zlphretort.com or connect with us on WhatsApp at +86 15315263754.