ZLPH leads the new revolution of intelligent production of bagged pre-prepared food, and the full process automation technology of sterilization breaks through the bottleneck of the industry

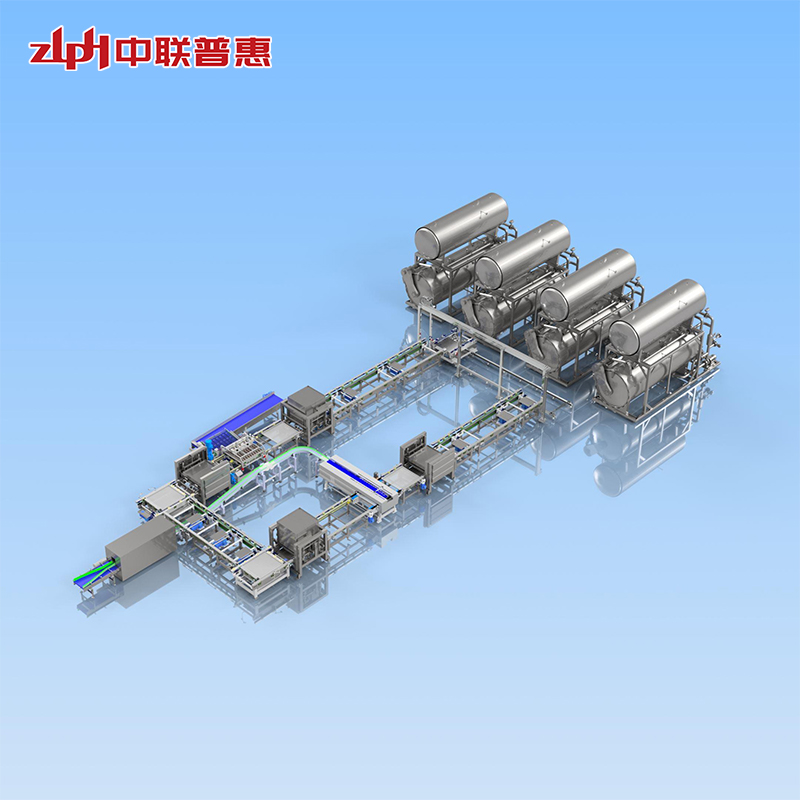

With the explosive growth of the pre-prepared food industry, consumers’ demand for product safety and production efficiency is increasing. As an innovative pioneer in the field of food processing equipment, ZLPH has launched a new generation of bagged pre-prepared food complete line solutions, especially integrating RGV intelligent transportation system, bag machine automatic tray loading, pressing and flipping unloading technology and automatic tray unloading system in the sterilization process, realizing the full process automation from product loading, sterilization to unloading, providing the industry with efficient, safe and intelligent production paradigm.

I. Pain points in the production of bagged pre-prepared meals: manual dependence and efficiency bottlenecks

Bagged pre-prepared meals have become the mainstream of the market due to their rich variety and convenient consumption. However, in the traditional production process, the sterilization link generally faces three major problems:

Low efficiency of manual loading: bagged products need to be neatly stacked on the sterilization tray, which is time-consuming and easy to cause uneven stacking of products, affecting the sterilization effect;

Easy to lose during transportation: the manual pushing and pulling of traditional carts causes the products to shake, which may cause damage to the packaging bags;

The unloading process is cumbersome: manual turning over after sterilization is prone to cross contamination, and the sorting of empty trays is time-consuming and laborious.

ZLPH targets the pain points of the industry and reconstructs the entire sterilization process with automation technology to promote the upgrade of pre-prepared meal production to “unmanned and precise”.

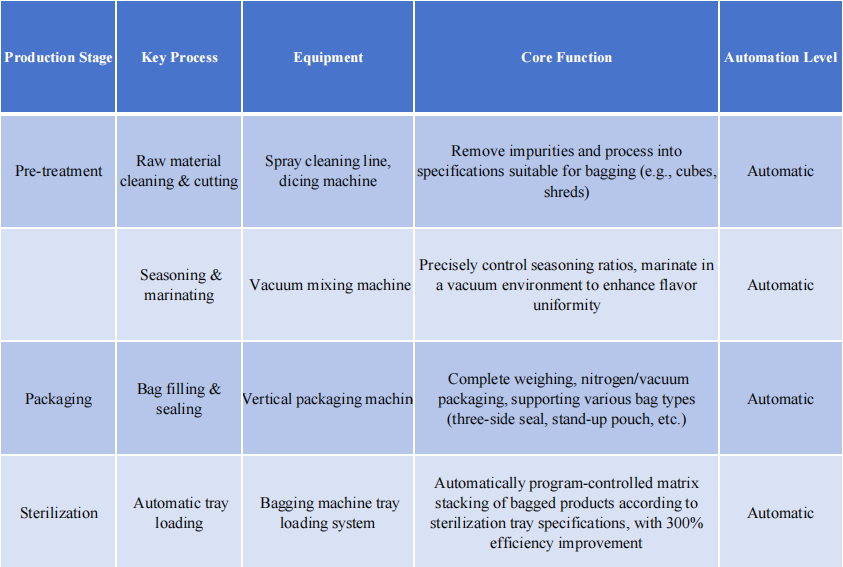

II. Core technology of sterilization: full process automation solution

1. Automatic tray loading by bagging machine: precise positioning and efficient stacking

The tray loading system of bagging machine developed by ZLPH adopts automatic program control technology, which can intelligently sort and neatly stack bagged pre-prepared dishes:

Matrix tray: automatically arranges product spacing according to the specifications of the sterilization tray to ensure uniform heat transfer, and improves efficiency by 300% compared with manual tray loading;

Strong compatibility: supports a variety of bag types (three-side seal, self-supporting bag, etc.), and switches product specifications with one click.

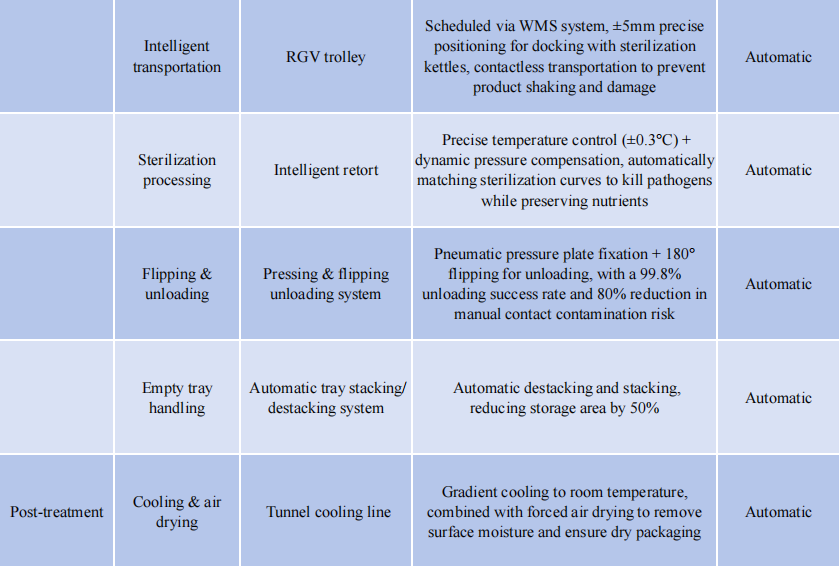

2. RGV trolley intelligent transportation: contactless throughout the process, precise docking with the retort

The RGV (rail-guided vehicle) system serves as the “intelligent porter” in the sterilization process, realizing fully automated transportation of products after loading:

Intelligent scheduling: through the linkage between the WMS system and the retort, the transportation route is automatically planned to improve logistics efficiency;

Precise docking: ±5mm positioning accuracy ensures seamless docking between the sterilization tray and the retort, avoiding product displacement caused by manual handling;

Full traceability: equipped with RFID tags, real-time recording of product batches, transportation time and other data, to achieve traceability of the entire production process.

3. Pressing and flipping unloading technology: unloading without damage to avoid secondary contamination

After sterilization, the pressing and flipping unloading system realizes automatic unloading through the dual actions of “pressing and fixing + flipping unloading”:

Flexible pressing: The pneumatic pressure plate gently presses the bagged product to prevent it from scattering during flipping;

Multi-angle flipping: 0-180° adjustable flipping angle, adapted to different product characteristics, unloading success rate reaches 99.8%;

Sanitary design: Stainless steel material and arc angle structure are easy to clean, meet food-grade hygiene standards, and reduce 80% of contact contamination risk compared to manual unloading.

4. Automatic unstacking system: empty tray sorting efficiency leaps

The matching automatic unstacking system can simultaneously complete the disassembly and stacking of empty sterilization trays:

Intelligent unstacking: The robotic arm automatically separates the stacked empty trays, with a single hourly processing capacity of 2,000; Space saving: The folding empty tray storage solution reduces the storage area by 50% and improves the space utilization rate of the workshop.

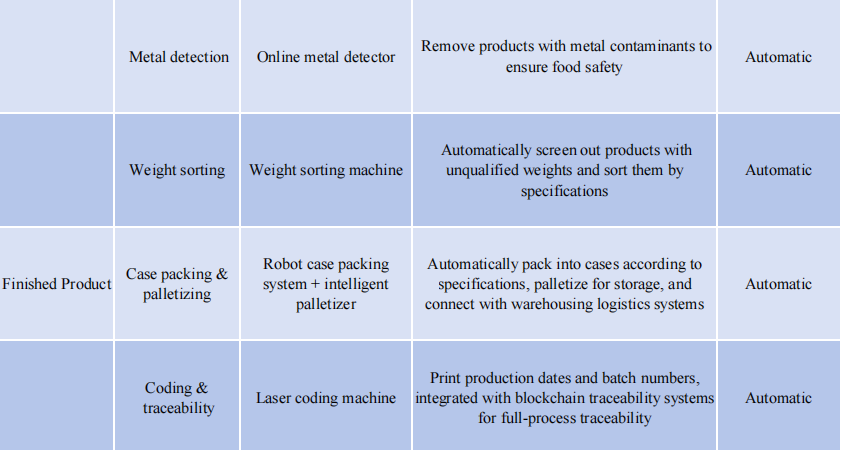

III. Improvement of whole-line efficiency: Double breakthrough in efficiency and safety

After China’s leading pre-prepared food company Zishan introduced the ZLPH bagged pre-prepared food whole-line solution, its production efficiency was significantly improved. Through full-process automation, the company not only solved the problem of manual dependence, but also achieved “zero error and zero pollution” in the sterilization process. The production manager of Zishan Group said: “ZLPH’s technology has increased the sterilization uniformity of bagged products to 99.2%, and the shelf life stability of the products has been significantly enhanced. At the same time, the production efficiency has been greatly improved, and the labor cost has been significantly reduced.” 4. Future Outlook: Intelligent and Flexible Upgrade

The relevant technical manager of ZLPH revealed that the company is promoting the application of AI visual inspection and robot adaptive control technology in bagged pre-prepared food production lines:

AI quality monitoring: embedding visual inspection modules in the loading and unloading links to identify problems such as damaged packaging bags and crooked stacking in real time;

Flexible production unit: through modular design, fast switching of products of different categories and specifications can be achieved to meet the multi-SKU production needs of pre-prepared food companies.

As the pre-prepared food industry develops towards standardization and scale, ZLPH's whole-line automation technology with sterilization as the core is becoming a key engine to promote industry upgrading. In the future, the company will continue to deepen the “technology + service” dual-wheel drive to help more food companies build a safe, efficient and intelligent production system.

If you're interested in learning more about our ZLPH Retort or exploring potential cooperation opportunities, feel free to reach out to us via email at saleshayley@zlphretort.com or connect with us on WhatsApp at +86 15315263754.