ZLPH Deepens Its Expertise in Core Canned Sterilization Technology, Empowering Food Processing Upgrades with Full-Line Supporting Services

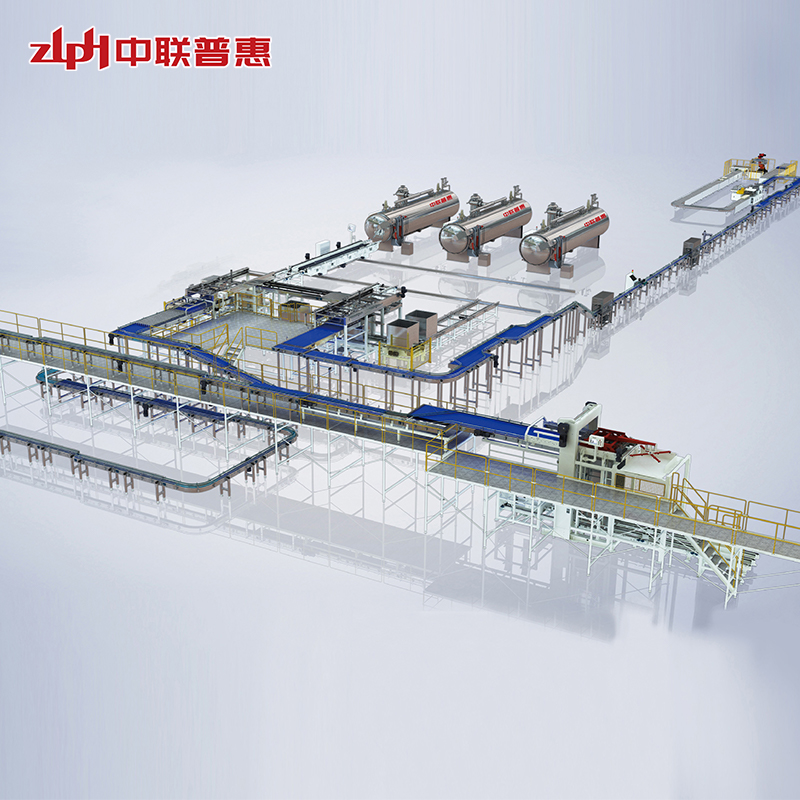

In the context of the food processing equipment industry’s accelerated transformation toward intelligence and specialization, ZLPH has established itself as a trusted partner for numerous food enterprises with its strategic positioning of “focusing on core technology and empowering full-line production,” leveraging its remarkable technological innovations in the field of canned sterilization. While the company specializes in the research and development of core equipment and technologies for the sterilization process, it can also provide full-line supporting services to customers based on its profound industry accumulation, helping food processing enterprises achieve efficient production.

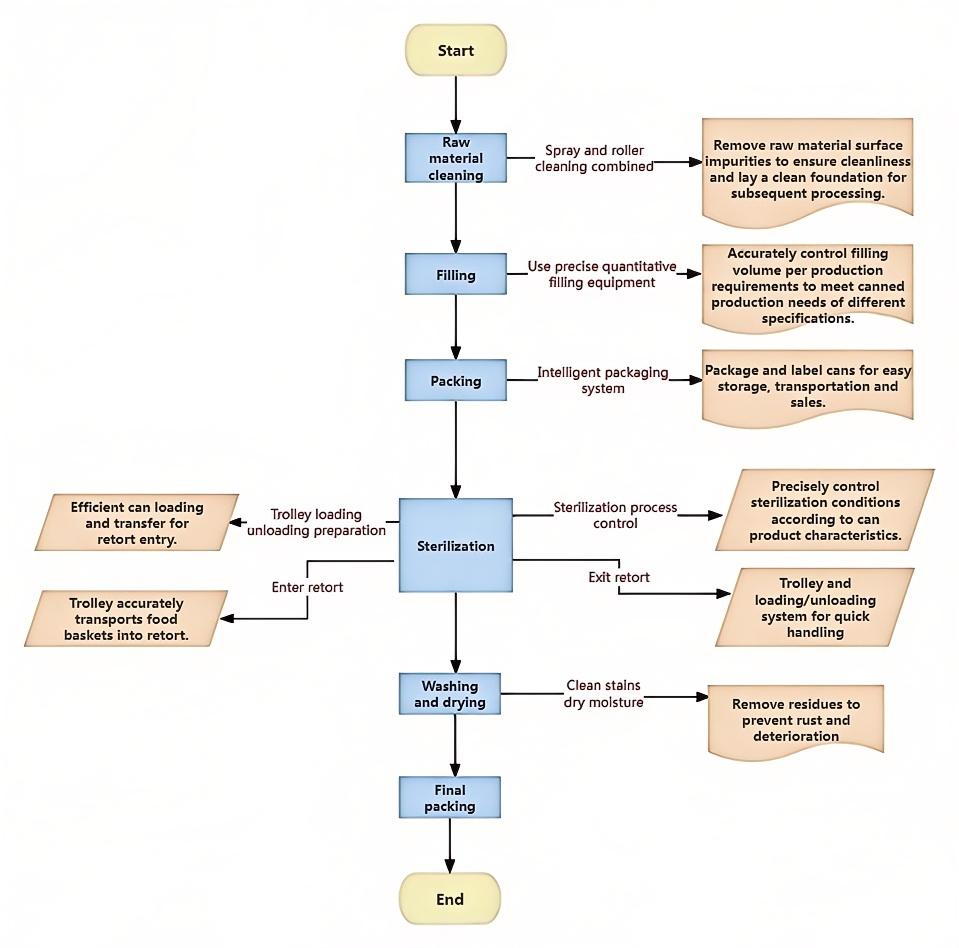

ZLPH clearly anchors its core business in the sterilization process of canning production. For processes such as raw material cleaning, filling, packaging, and cleaning-drying, although they are not the company’s primary focus, ZLPH can still provide professional supporting solutions and equipment docking services to customers based on its rich industry resources and technical expertise. Whether it is the spray cleaning equipment required for the cleaning process, the quantitative filling devices for the filling process, or various equipment for packaging and cleaning-drying processes, ZLPH can select suitable high-quality supplier resources according to customer needs to help customers build complete canned production lines and solve their one-stop procurement and equipment adaptation challenges.

In the core sterilization process, ZLPH demonstrates unparalleled technical strength. The company’s self-developed retort is a model of technological innovation in the industry, equipped with an intelligent temperature control system and dynamic pressure compensation technology to achieve precise control of the sterilization process. The temperature control accuracy can reach ±0.3°C, and the pressure fluctuation range is strictly controlled within ±0.02MPa, ensuring precise adjustment of temperature and pressure parameters under different sterilization process requirements. The retort can automatically match the optimal sterilization curve according to food characteristics, efficiently killing pathogenic microorganisms such as Clostridium botulinum and Salmonella, while maximizing the retention of food color, taste, and nutrients. Take the production of a well-known brand of yellow peach canned food as an example: after treatment in ZLPH’s retort, the product’s vitamin C retention rate reaches 92%, far exceeding the industry average, providing a solid guarantee for food enterprises to improve product quality.

ZLPH’s trolley and loading/unloading cage system further provides strong support for the efficient operation of the retort. The trolley, manufactured from high-strength alloy steel, can carry 6-8 groups of customized sterilization baskets at a time and is equipped with AGV intelligent guidance technology to achieve precise positioning within ±5mm, ensuring safe and stable loading/unloading processes. The loading/unloading cage adopts a honeycomb-style hollow structure design, which significantly increases heat transfer efficiency by 40%, ensuring uniform heating of each can during sterilization. The application of a pneumatic quick-locking device enables the completion of full-cage loading/unloading within 30 seconds, increasing efficiency by nearly 10 times compared to traditional manual operations, significantly reducing labor costs and intensity, and effectively improving the overall production capacity of the production line.

“We have always insisted on deepening our expertise in core sterilization technology while also hoping to create greater value for customers through our full-line supporting services,” said ZLPH’s technical director. “From optimizing sterilization process parameters to assisting customers in selecting and docking full-line equipment, our professional team will provide comprehensive technical support and services throughout the process.” Currently, ZLPH has reached deep cooperation with more than 20 domestic food enterprises, providing them with core sterilization equipment and full-line supporting services. For example, after a large aquatic product canned food enterprise introduced ZLPH’s solutions, not only did the efficiency of the sterilization process significantly improve, but under the coordinated operation of the full-line equipment, its annual production capacity increased by 60%, and the product defect rate dropped to 0.3%, achieving a dual leap in production efficiency and product quality.

Looking to the future, ZLPH will continue to increase its R&D investment in sterilization technology to further enhance sterilization precision and intelligence. At the same time, the company will continuously optimize its full-line supporting service system, integrate more high-quality industry resources, and promote the food processing industry’s advancement toward efficiency, intelligence, and sustainability with more professional technologies and more comprehensive services.

If you're interested in learning more about our ZLPH Retort or exploring potential cooperation opportunities, feel free to reach out to us via email at saleshayley@zlphretort.com or connect with us on WhatsApp at +86 15315263754.