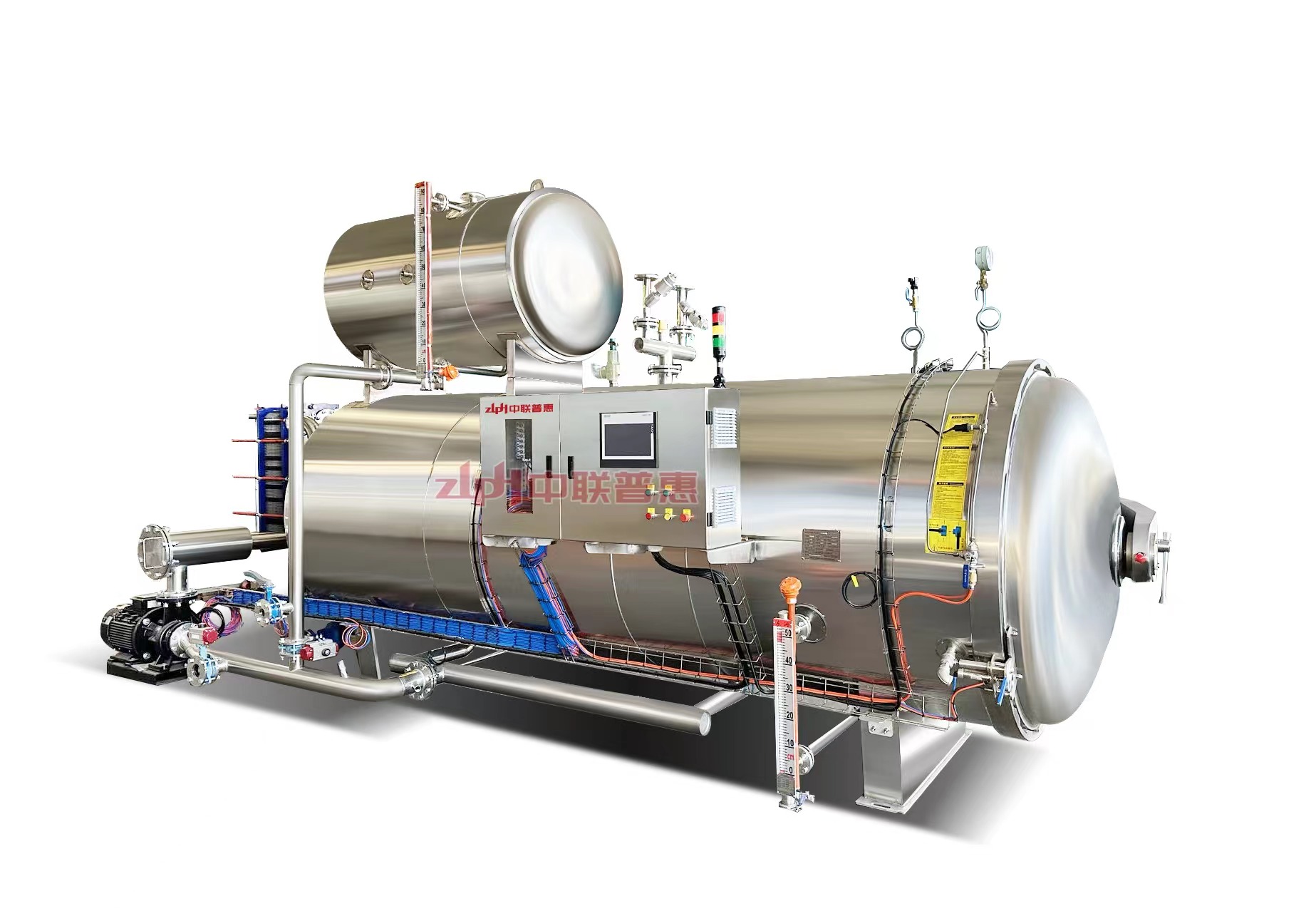

Recently, in the field of food processing machinery, a scientific revolution around the materials of autoclaves is quietly emerging. Traditional autoclaves often face the dilemma of balancing durability and hygiene in long-term use. With the emergence of new composite materials and advanced metal processing technology, this problem has been gradually overcome.

According to the industry's leading R&D team, they have developed a new generation of autoclave materials by combining high-strength, corrosion-resistant alloy materials with new antibacterial coatings. This material can not only withstand frequent use in high-temperature and high-pressure environments, greatly extending the service life of the equipment, but its unique antibacterial properties effectively prevent bacterial growth and residue, ensuring hygiene and safety during food processing.

Many food production companies have reported after trialling the new autoclave that the new equipment has significantly improved product quality and hygiene standards while reducing maintenance costs, giving companies an advantage in the fierce market competition. Industry experts predict that with the further advancement of this material science revolution, the autoclave industry will usher in new development opportunities, and the application of related technologies will also bring innovation and breakthroughs to more food processing links.