In the long standing journey of delving into the Russian market, ZLPH has witnessed a remarkable and continuous upsurge in its cooperation with Russian clients. Our company, with a long established reputation in the manufacturing industry, has always been committed to technological innovation and quality improvement. Since its inception, we have been adhering to the principle of “quality first, customer oriented”, and have made unremitting efforts to provide high quality products and services to the global market.

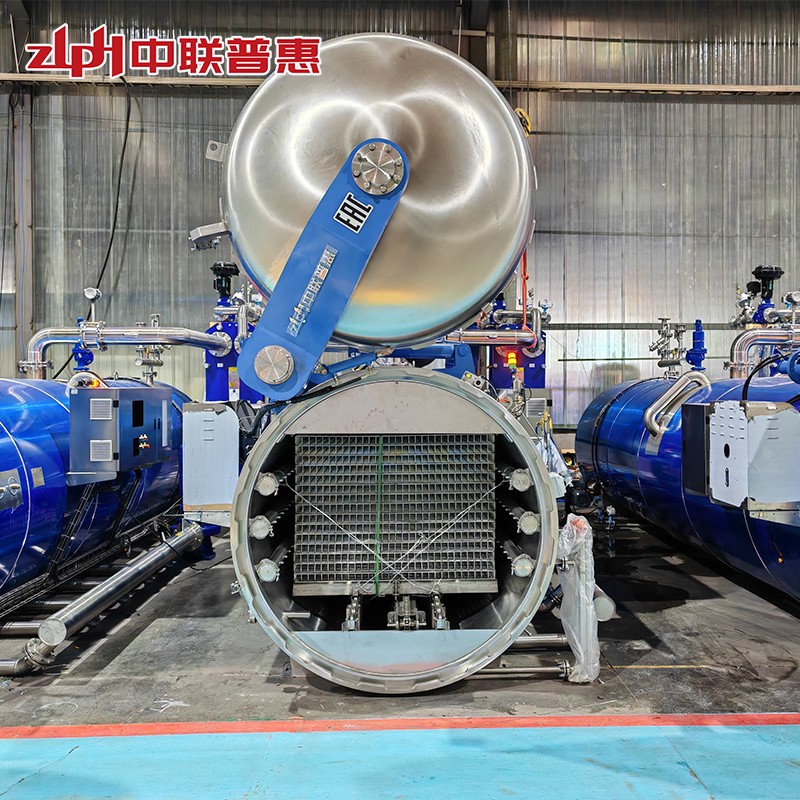

In recent times, the autoclave meticulously developed by our R & D team has successfully passed a series of rigorous tests. These tests were not only a formality but a comprehensive assessment of the product’s performance under various extreme conditions. The development process of this autoclave was filled with challenges. Our R & D team had to overcome numerous technical difficulties, from the selection of high quality materials to the optimization of the internal structure of the equipment, in order to ensure that the final product could meet the highest standards of the industry.

Before the shipment, our professional technical team, composed of experienced engineers and technicians, carried out multiple rounds of simulation tests on the key performance indicators of the autoclave. In the temperature control test, they used advanced temperature sensing devices to monitor the temperature distribution inside the autoclave. By adjusting the heating elements in real time, they achieved an extremely uniform temperature distribution, with the temperature difference controlled within a negligible range. This ensures that every part of the food and beverage products being sterilized is evenly heated, preventing over heating or under heating that could otherwise affect the quality and taste of the products.

In the pressure resistance test, the team simulated various high pressure environments that the autoclave might encounter during actual operation. The autoclave’s pressure control system, equipped with advanced sensors and intelligent control algorithms, responded promptly and accurately. It could adjust the internal pressure according to the preset parameters, ensuring the safe and stable operation of the equipment even under extreme pressure conditions. After multiple rounds of such strict tests, all the performance indicators of the autoclave far exceeded the initial expectations, which is a strong testament to its outstanding quality and reliability.

This batch of autoclaves is destined for the food and beverage industry in Russia. In the food and beverage production process, the sterilization step is of vital importance. It is not only related to the shelf life and safety of the products but also to the preservation of their nutritional value and flavor. Our autoclaves are equipped with state of the art sterilization technology, can effectively eliminate a wide range of microorganisms, including bacteria, viruses, and molds, with a sterilization rate reaching an astonishing level.

Moreover, our unique design of the sterilization process is aimed at minimizing the damage to the nutritional components and flavor of food and beverages. Through precise control of temperature, pressure, and sterilization time, we can retain most of the vitamins, minerals, and natural flavors in the products. This not only meets the strict quality requirements of the modern food and beverage market but also caters to the growing demand of consumers for healthy and delicious food.

In the past few years, our products have been successfully applied in many projects in Russia. For example, a well known Russian dairy company has been using our autoclaves in their production lines. According to their feedback, after using our equipment, the product qualification rate has increased significantly, from the previous 88% to the current 96%. At the same time, the production efficiency has also been improved by 35%, and the production cost has been reduced by 15% due to the more efficient sterilization process and lower energy consumption. Another Russian juice producing enterprise also reported that our autoclaves have effectively solved their problem of product spoilage during storage, greatly extending the shelf life of their juice products.

We firmly believe that with our advanced technology, excellent product quality, and professional after sales service, this new batch of autoclaves will further assist local food and beverage enterprises in Russia to enhance their production efficiency and product quality. By improving the quality of their products, these enterprises will be able to gain a larger share in the highly competitive market, both domestically and internationally. This, in turn, will also strengthen our brand image in the Russian market and lay a solid foundation for our future cooperation.

Looking ahead, our company will continue to focus on technological innovation. We are actively collaborating with world renowned scientific research institutions and industry experts. Through joint research projects and technology exchanges, we are constantly exploring new materials, new processes, and new sterilization methods.

In addition, we plan to expand our global business scope based on our existing technology and rich market experience. We will establish more local service centers in different regions around the world to provide more timely and professional after sales services to our customers. For the food and beverage industry, we will continue to provide customized sterilization solutions. By deeply understanding the specific needs of different food and beverage products, such as the sterilization requirements of meat products, canned foods, and beverages, we can design and manufacture autoclaves that are more suitable for their production processes.

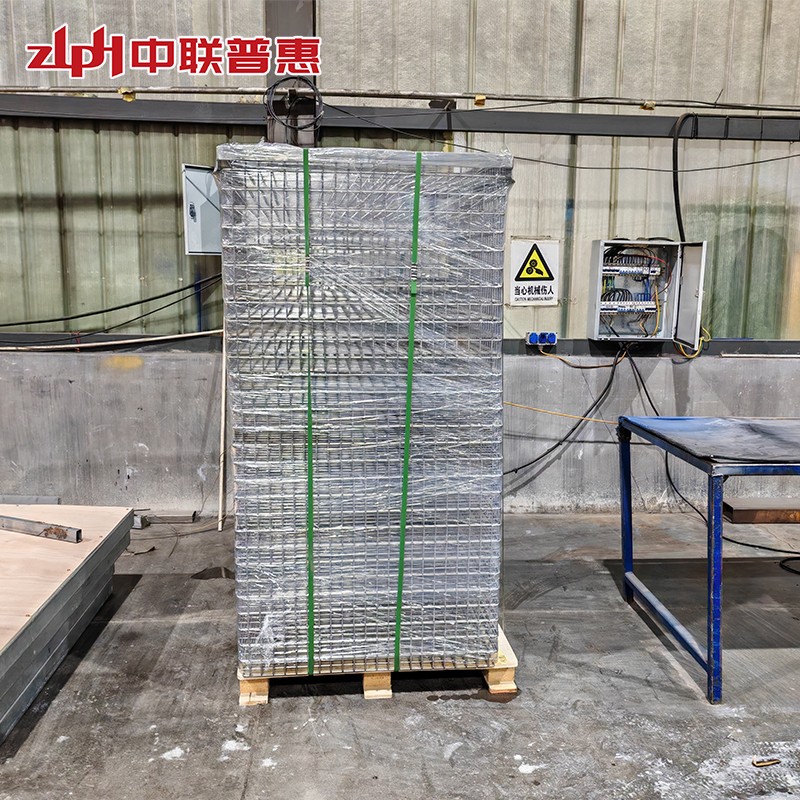

In conclusion, the shipment of this batch of autoclaves to Russia is not only a business transaction but also a significant step in promoting the development of the food and beverage industry in Russia. It is also an important manifestation of our company’s global strategy. We are confident that in the future, with our continuous efforts in technology research and development and market expansion, we will make greater contributions to the global food and beverage industry and lead the industry towards a more high quality and sustainable development path.