Against the backdrop of increasingly close global trade and industrial technology exchanges, our company has received exciting news. After months of unremitting efforts and close collaboration by the R&D team, production department and quality inspection team, two ASME (American Society of Mechanical Engineers)-compliant water immersion autoclaves have successfully completed the production process, and all performance indicators have met or even exceeded expectations. They are about to cross the vast Pacific Ocean and be shipped to the US market. This achievement is not only a strong proof of our company’s production and manufacturing capabilities, but also marks another solid and far-reaching step for our company in the field of international high-end sterilization equipment.

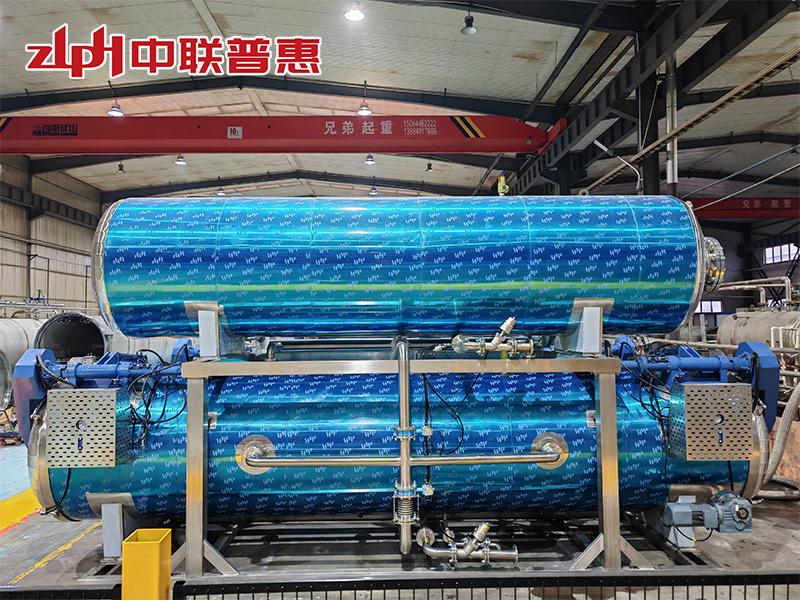

The water immersion autoclaves exported this time strictly follow the ASME standards in the design and manufacturing process, starting from the source control of raw materials, and selecting high-quality special steel to ensure that the products have excellent pressure resistance, high temperature resistance and long-lasting durability. In terms of production technology, advanced automated welding technology and precision machining technology are used to ensure the structural accuracy and sealing of the equipment. In terms of safety, it is equipped with multiple safety interlock devices to prevent safety accidents caused by misoperation; in terms of reliability, the stable and reliable operation performance of the equipment has been verified by simulating long-term operation tests under various complex working conditions; the high efficiency is reflected in its unique water immersion heating system, which uses circulating hot water spray technology and an intelligent temperature control module to make the inside of the autoclave reach the preset temperature in a very short time and maintain a high-precision constant temperature of ±0.5℃, achieving a more uniform temperature distribution. Compared with traditional sterilization methods, it effectively improves the sterilization effect by more than 30%. This efficient and stable sterilization method can fully meet the stringent requirements of American food industry customers for product quality and production efficiency. For example, in canned food processing, it can shorten the sterilization time of canned food by 20% and reduce energy consumption by 15%, greatly helping food processing companies to reduce production costs, extend the shelf life of food, and ensure food safety from the source.

This export to the United States is an important milestone in our company's internationalization strategy. It not only reflects the high recognition of American customers for our product quality and technical strength, but also builds a solid bridge for our company to further expand the international market. In the process of cooperating with American customers, we have a deep understanding of the local food industry’s regulations and policies, market demand, and the actual production pain points of enterprises, which provides a valuable basis for the localization improvement and customized services of subsequent products. In the future, we will take this export as an opportunity to continue to increase investment in R&D and innovation, set up a R&D team composed of experts in multiple fields such as materials science, mechanical engineering, and automation control, continuously optimize product performance, and develop more autoclave series products that meet the needs of different customers. At the same time, we plan to set up an after-sales service center in the United States, equipped with a professional team of technical engineers, to provide customers with 24*7 technical support, equipment maintenance, and operation training and other one-stop services, to further enhance customer satisfaction and brand loyalty. In addition, we actively participate in international food processing industry exhibitions and technical seminars, strengthen exchanges and cooperation with food companies and industry experts around the world, expand overseas market territory, and strive to provide high-quality, efficient, and customized autoclave solutions for customers in more countries and regions around the world, deeply participate in and promote the vigorous development of the global food industry.