Upgraded Retort Technology Empowers Fresh Rice Noodle Industry to Achieve Quality Leap

As the fresh rice noodle market continues to expand, consumers are paying increasing attention to product quality and safety. As a key link determining the quality and shelf life of fresh rice noodles, the sterilization process is undergoing a revolutionary transformation, with the upgrading of retort technology serving as the core driving force behind this change.

Precise Temperature Control: Ensuring Efficient Sterilization and Stable Quality

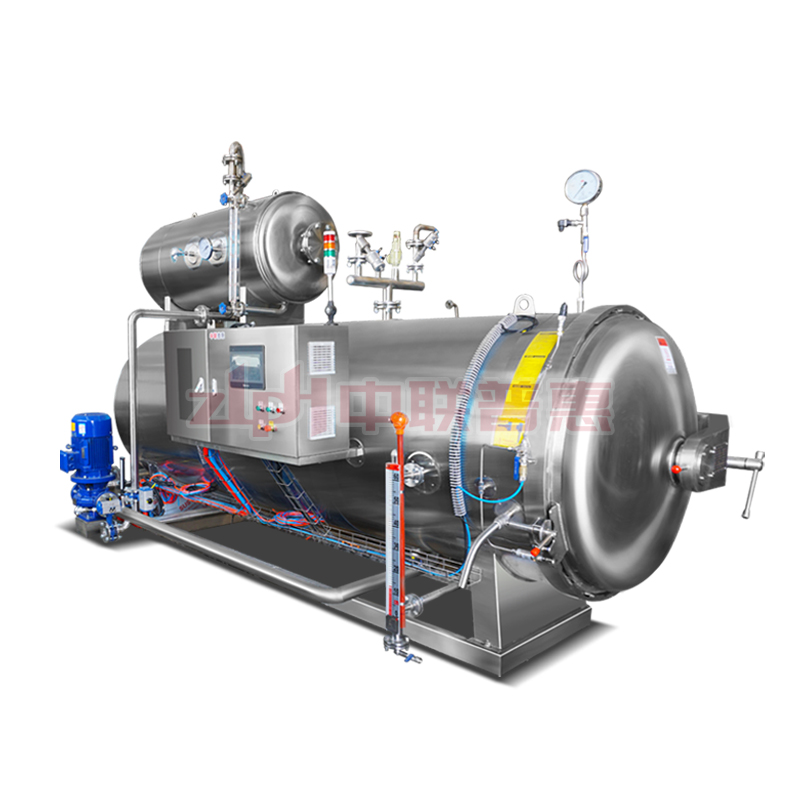

When processing fresh rice noodles, traditional retorts often suffer from uneven temperature distribution, leading to incomplete sterilization of some noodles, increased risk of residual microorganisms, and even local overheating— which impairs the noodles’ texture and causes nutrient loss. Today, advanced retorts are equipped with cutting-edge intelligent temperature control systems, enabling precise regulation of temperature fluctuations within an extremely narrow range. For instance, high-end retorts can achieve a temperature control accuracy of ±0.5℃.

Take a well-known fresh rice noodle manufacturer as an example: after adopting advanced retorts, the company maintains a standard sterilization temperature of 121℃, ensuring every batch of noodles is evenly heated. This effectively eliminates harmful microorganisms such as E. coli and Staphylococcus aureus, reducing the product’s microbial non-compliance rate from 10% to less than 1%. Moreover, precise temperature control prevents issues like noodle breakage and gelatinization caused by overheating, significantly preserving the noodles’ texture and freshness—boosting consumer satisfaction by 20%.

Innovative Sterilization Methods: Extending Shelf Life While Preserving Flavor

Fresh rice noodles have high water content. Although traditional high-temperature, long-duration sterilization ensures sterilization effectiveness, it severely damages the noodles’ texture and nutrients, and shortens their shelf life. To address this problem, advanced retorts have introduced a variety of innovative sterilization methods.

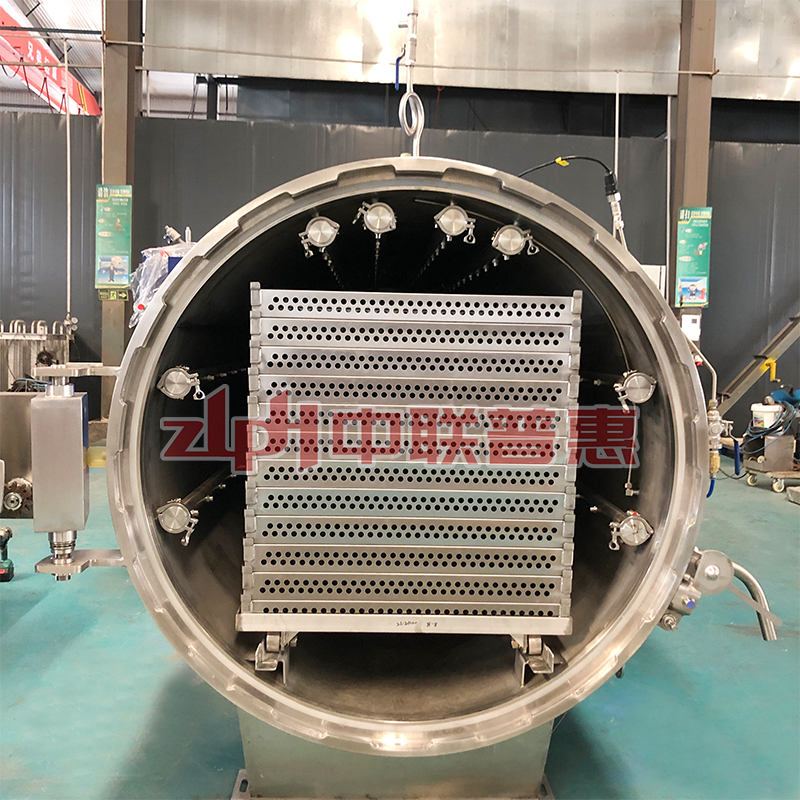

Spray sterilization uses spray devices (installed on the top or sides) to evenly spray high-temperature hot water onto packaged rice noodles, achieving rapid and uniform heating for sterilization. This method greatly shortens sterilization time and reduces the noodles’ exposure to heat, maximizing the retention of their original flavor and nutrients. According to professional testing, fresh rice noodles treated with spray retorts have a B-vitamin retention rate of over 90%, and their room-temperature shelf life extends to 3 months—doubling that of noodles processed via traditional sterilization.

In addition, for fresh rice noodles sensitive to temperature, a low-temperature short-time sterilization process has been developed. Operating at a relatively low temperature of 60-80℃ with precise time control, this process not only achieves effective sterilization but also maintains the noodles’ optimal texture and elasticity, meeting market demand for high-quality fresh rice noodles.

Improved Production Efficiency & Reduced Energy Consumption: Supporting Enterprise Development

Against the backdrop of intensifying market competition, fresh rice noodle manufacturers have an urgent need to improve production efficiency and control costs. Advanced retorts feature comprehensive design optimizations that significantly reduce heating and cooling times, effectively boosting production efficiency. Some retorts are equipped with high-efficiency steam generation systems and rapid exhaust devices, shortening the production cycle of each batch by 20%-30%.

For example, a medium-sized fresh rice noodle factory originally had a daily output of 5 tons. After replacing with advanced retorts, its daily output increased to 7 tons, effectively meeting the growing market demand. Meanwhile, in terms of energy conservation, advanced retorts adopt high-performance thermal insulation materials and heat recovery technologies to significantly reduce energy consumption. Heat recovery systems recycle waste heat generated during sterilization for preheating the next batch of products or supplying other production processes, improving energy utilization by over 20%. This greatly lowers enterprises’ production costs and enhances the market competitiveness of their products.

Customized Design: Adapting to Diverse Production Needs

Considering the varied scales of fresh rice noodle manufacturers and the wide range of product types, retort suppliers offer customized services:

For small enterprises (with low output and flexible product lines), compact retorts with easy operation are designed to meet needs for small-batch, multi-variety production. The investment cost of such equipment is over 50% lower than that of large-scale retorts.

For large-scale enterprises, high-automation, continuous-operation retorts are available to enable efficient and stable mass production.

For fresh rice noodles with different packaging forms (e.g., bagged, boxed) and formulas, retorts can be customized with exclusive sterilization protocols based on product characteristics. For instance, for composite fresh rice noodles (with added vegetables, meat, etc.), sterilization temperature and duration are adjusted to ensure thorough sterilization of ingredients without affecting the noodles’ texture; for fresh rice noodles using new packaging materials, sterilization processes are optimized to ensure packaging integrity and sealing—providing comprehensive technical support for enterprises.

As consumers’ demands for food safety and quality continue to rise, the fresh rice noodle industry is facing new development opportunities and challenges. With distinct advantages such as precise temperature control, innovative sterilization methods, energy efficiency, and customized design, advanced retorts are becoming a powerful tool for fresh rice noodle enterprises to improve product quality and enhance market competitiveness—driving the entire industry toward a safer, more delicious, and more efficient future.