ZLPH: A Quality Innovation Tool for Glutinous Rice Shoot Processing

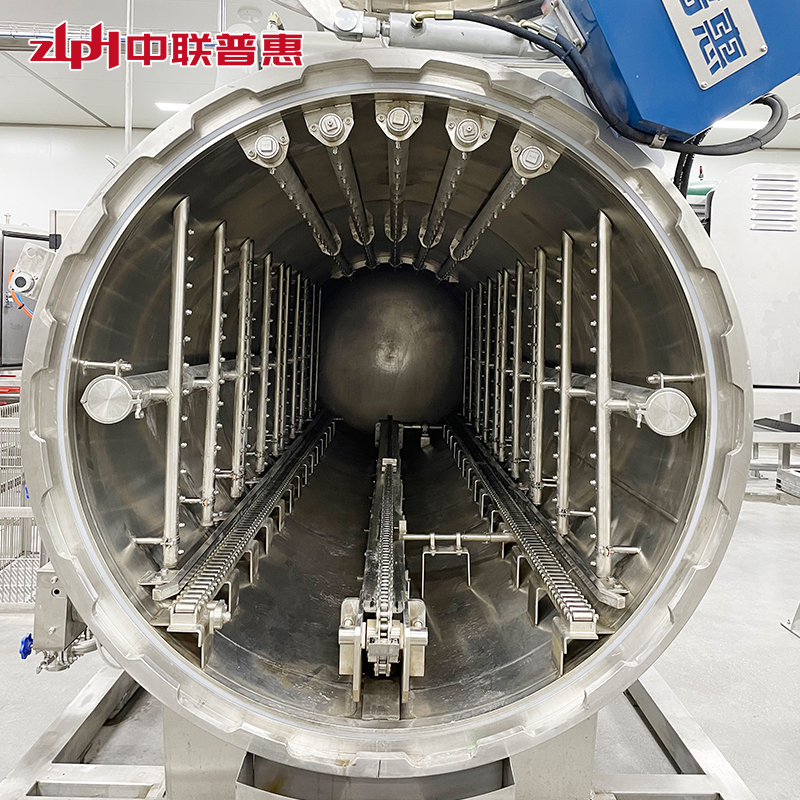

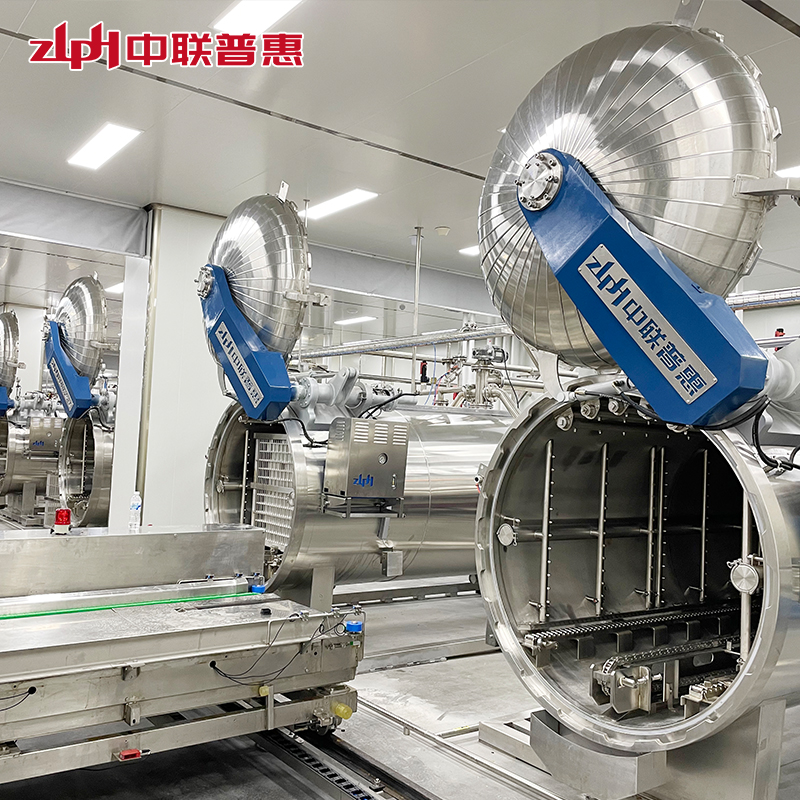

I. Three-Dimensional Spraying System: Revolutionizing Traditional Sterilization

The ZLPH side water spray retort and top water spray retort adopt a dual-spray structure (side-spray + top-spray) to create a 360° dead-angle-free sterilization environment:

Top Water Spray Module: Dense nozzles at the top vertically cover the surface with mist-like wave-shaped hot water, ensuring uniform heating of the upper layer of glutinous rice shoots and the top of packaging bags. This is particularly suitable for upper-layer penetration when products are stacked in bags, avoiding temperature differences caused by "upper-layer coldness and lower-layer hotness."

Side Water Spray Module: Arrayed side nozzles precisely target the gaps between each layer of trays, with water flow directly penetrating the stacked gaps to drive the sterilization medium into a spiral circulation. This solves the industry problem of delayed heat transfer in lower-layer products caused by tray stacking in traditional water immersion sterilization.

Technical Breakthrough: Compared with traditional water immersion sterilization, thermal distribution uniformity is increased by 30%, sterilization time is shortened by 15%-20%, and efficiency is significantly improved under the same production capacity.

II. Intelligent Temperature Control and Pressure Coordination: Safeguarding Product Quality with Precision

(1) Temperature Control Technology

Linear Heating: Equipped with a PLC + touchscreen fully automatic control system, it uses gentle gradient heating for sensitive packaging (such as aluminum foil bags) to avoid packaging rupture caused by sudden temperature changes;

Precision Assurance: Temperature control accuracy reaches ±0.3°C, ensuring each bag of glutinous rice shoots undergoes precise heat treatment to avoid fiber softening or nutrient loss caused by local overheating.

(2) Dynamic Pressure Compensation Technology

A high-precision pressure sensor built in real-time monitors the internal air pressure of the packaging, and automatically inflates/deflates through a proportional control valve to limit pressure fluctuations within ±0.03Bar, improving accuracy by 40% compared to traditional equipment.

Core Advantage: Completely solves the problem of bulging and bursting of vacuum packaging bags caused by internal and external pressure differences, especially suitable for soft-packaged products with soup like glutinous rice shoots, ensuring an appearance integrity rate of over 98%.

III. Energy Efficiency: Redefining Production Costs

(1) Water Resource Recycling

After being filtered by a stainless steel filter system (50μm precision), the sprayed water can be reused for 3-5 batches, with a water saving rate of over 60%, significantly reducing water consumption in industrial production.

(2) Heat Recovery Technology

After sterilization, high-temperature water preheats the cold water in the next kettle through a heat exchanger, increasing energy utilization by 45% and reducing energy consumption costs by approximately 80 RMB per ton of products, balancing environmental protection and economic benefits.

IV. Quality Improvement: Data Witnesses Outstanding Performance

(1) Taste and Texture Optimization

Brittleness Retention: Through precise temperature control and water flow impact stirring, the brittleness retention value of glutinous rice shoots is increased by 20%, perfectly preserving the original sweet, fresh, and crispy taste.

Nutrient Retention: The vitamin C retention rate is increased from 60%-65% to 75%-80%, significantly reducing the loss of nutrients such as dietary fiber, achieving a dual guarantee of deliciousness and health.

(3) Microbial Control

Total bacterial count after sterilization ≤5CFU/g (traditional process ≤10CFU/g), far exceeding commercial sterility standards. Combined with dynamic pressure compensation technology, it can achieve a 12-month shelf life at room temperature for glutinous rice shoots, providing a solid guarantee for long-distance transportation and shelf display.

V. Operation and Maintenance: Balancing Intelligence and Convenience

(1) Fully Automatic Control System

One-touch operation starts the sterilization program, with the entire process monitored in real-time by PLC and touchscreen, reducing manual intervention and operational errors, especially suitable for large-scale production scenarios.

(2) Maintenance-Friendly Design

Quick-Detachable Nozzle Structure: Supports rapid disassembly and cleaning. Daily maintenance only requires removing impurity residues, and blockage inspection and dredging disinfection are carried out weekly;

Modular Filtration System: The filter element is replaced weekly, and the pipeline tightness is fully inspected monthly to ensure long-term stable operation of the equipment.

Conclusion

The ZLPH side water spray retort and top water spray retort solve the pain points of uneven thermal distribution, packaging damage, and nutrient loss in glutinous rice shoot sterilization through three core technologies: three-dimensional spraying, intelligent temperature control, and pressure coordination, providing food processing enterprises with an efficient, energy-saving, and high-quality sterilization solution. Whether in taste retention, shelf life extension, or production cost optimization, this equipment demonstrates significant technological leadership, helping enterprises build a quality competition barrier in the leisure food market.

If you're interested in learning more about our ZLPH Retort or exploring potential cooperation opportunities, feel free to reach out to us via email at saleshayley@zlphretort.com or connect with us on WhatsApp at +86 15315263754.