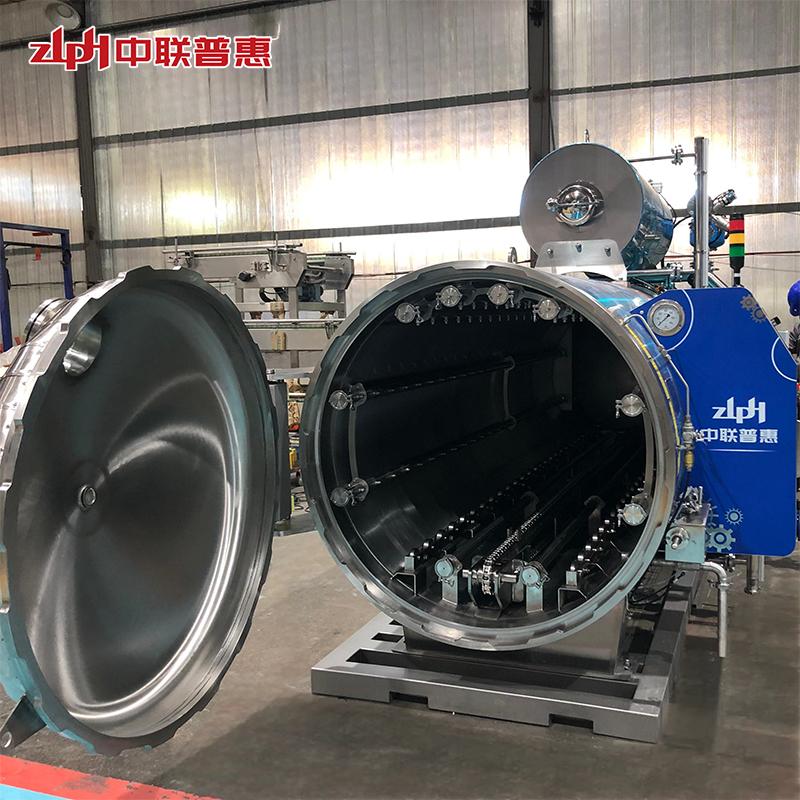

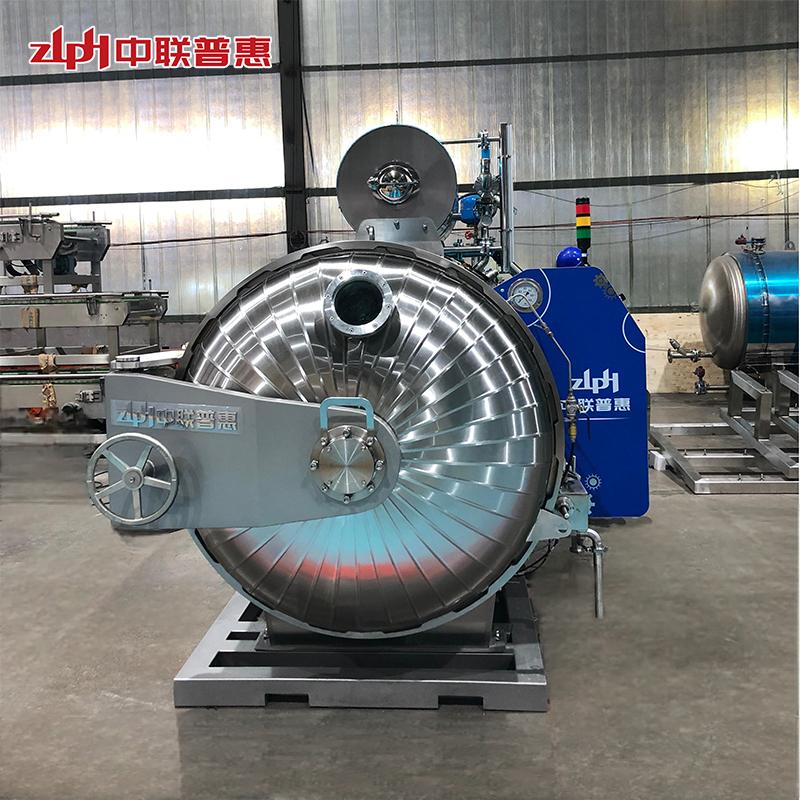

ZLPH Water Spray Retort: An Economical and Reliable Sterilization Solution for Glass Jar Foods

In the food processing industry, glass jar foods are deeply favored by consumers due to their excellent sealing properties, corrosion resistance, and environmental friendliness. Glass jars can not only effectively preserve the flavor of the food but also allow consumers to intuitively see the quality of the contents. However, during the production process of glass jar foods, because the glass material is quite sensitive to temperature changes, improper sterilization treatment is likely to cause the jars to break, affecting product quality and production efficiency. With its innovative technology and outstanding performance, the ZLPH water spray retort provides an economical and reliable sterilization solution for glass jar foods, becoming an ideal choice for numerous food enterprises.

Gentle Sterilization to Ensure the Integrity of the Jars

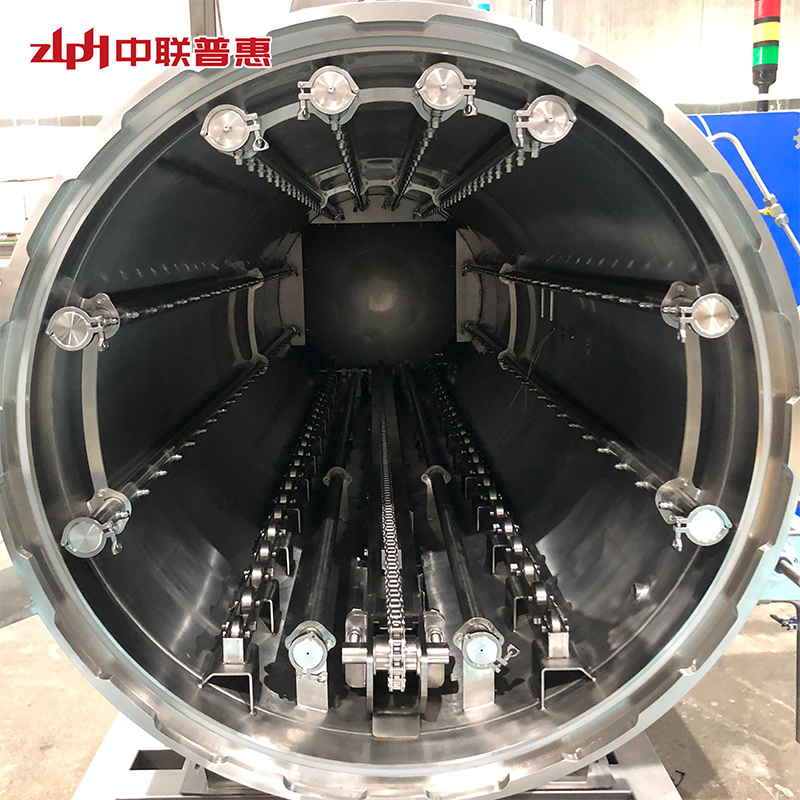

During the high-temperature sterilization process of glass jars, if the heat is uneven or the temperature changes drastically, problems such as breakage and bottle explosion are extremely likely to occur. Traditional sterilization methods are difficult to precisely control the rate of temperature change, resulting in a high scrap rate. The ZLPH water spray retort adopts advanced water spray technology, using uniform and fine water mist to carry out a surrounding heating and cooling of the glass jars. In the sterilization and heating stage, the water mist can quickly and evenly transfer heat to the inside and outside of the jars, avoiding local overheating. When cooling, the gentle water mist can make the jars cool down slowly, effectively relieving the thermal stress. Verified by actual production, when the ZLPH water spray retort is used to process glass jar foods, the bottle explosion rate is reduced to below 0.5%, greatly reducing the production losses of enterprises.

Precise Temperature Control to Lock in the Food Quality

The flavor and nutritional components of glass jar foods are very likely to be lost during the high-temperature sterilization process. The ZLPH water spray retort is equipped with a high-precision intelligent temperature control system, which can precisely set the sterilization temperature, time, and pressure parameters according to the characteristics of different glass jar foods. Compared with traditional sterilization equipment, for glass jar foods processed by the ZLPH water spray retort, the retention rate of nutritional components is increased by 20% - 30%, and the flavor restoration degree reaches over 85%.

High Efficiency and Energy Saving to Reduce Production Costs

In the increasingly competitive market, food enterprises are faced with the dual pressures of reducing production costs and improving production efficiency. Traditional sterilization equipment has high energy consumption and a long production cycle, seriously affecting the economic benefits of enterprises. The ZLPH water spray retort adopts a high-efficiency and energy-saving design. Its unique water circulation system can achieve the reuse of water resources, reducing water waste. The advanced heating and heat preservation technology effectively reduces energy consumption, saving more than 30% of energy compared with traditional sterilization equipment. In addition, this retort supports continuous production, and the hourly processing capacity can reach 2 - 3 times that of traditional equipment, greatly shortening the production cycle and helping enterprises quickly respond to market demands and enhance their market competitiveness.

Intelligent Operation to Stabilize Product Quality

The stability of product quality is the key for enterprises to establish a brand image. The ZLPH water spray retort is equipped with an automated intelligent control system. Operators only need to input relevant parameters on the touch screen, and the equipment can automatically complete the entire sterilization process. The system can monitor and adjust data such as temperature, pressure, and water level in real time, ensuring that each batch of glass jar foods can reach a unified high-quality standard. At the same time, the equipment has a fault warning function. Once an abnormal situation occurs, the system will immediately issue an alarm and automatically stop the machine, facilitating maintenance personnel to quickly troubleshoot problems and effectively avoiding product quality problems caused by equipment failures.

Whether it is a small food workshop or a large food production enterprise, the ZLPH water spray retort, with its remarkable advantages of gentle sterilization, precise temperature control, high efficiency and energy saving, and intelligent operation, provides comprehensive quality assurance for glass jar foods.

If you are interested in improving the production quality and efficiency of glass jar foods, you are welcome to contact us via email at saleshayley@zlphretort.com or on WhatsApp (+86 15315263754). We will provide you with professional solutions and high-quality services.