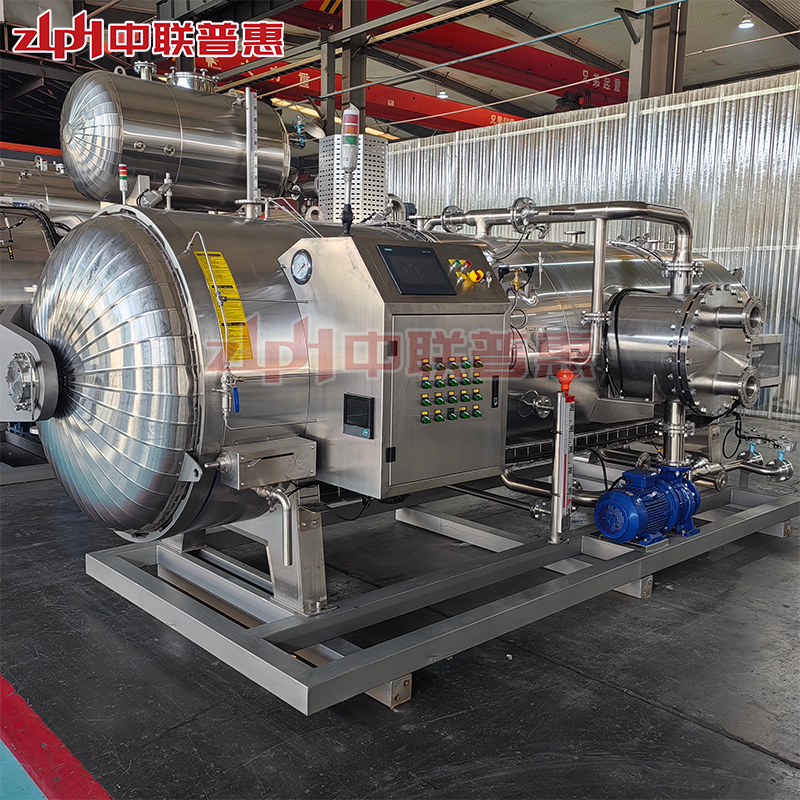

ZLPH Steam-air Retort: Key to Tuna Can Quality

In the fast-paced modern life, tuna canned food is widely favored due to its nutrition and convenience. From the tuna caught in the ocean to the canned food, the sterilization process is crucial for product quality and safety. The ZLPH Steam-air Retort, with its innovative technology and excellent performance, has become the core equipment for improving the quality of tuna canned food and promoting the development of the industry.

Efficient Cooperative Sterilization, Building a Solid Safety Defense Line

During the fishing, transportation, and processing of tuna, it is highly susceptible to microbial contamination. Traditional sterilization methods often fail to completely eliminate these stubborn microorganisms due to uneven heat transfer.

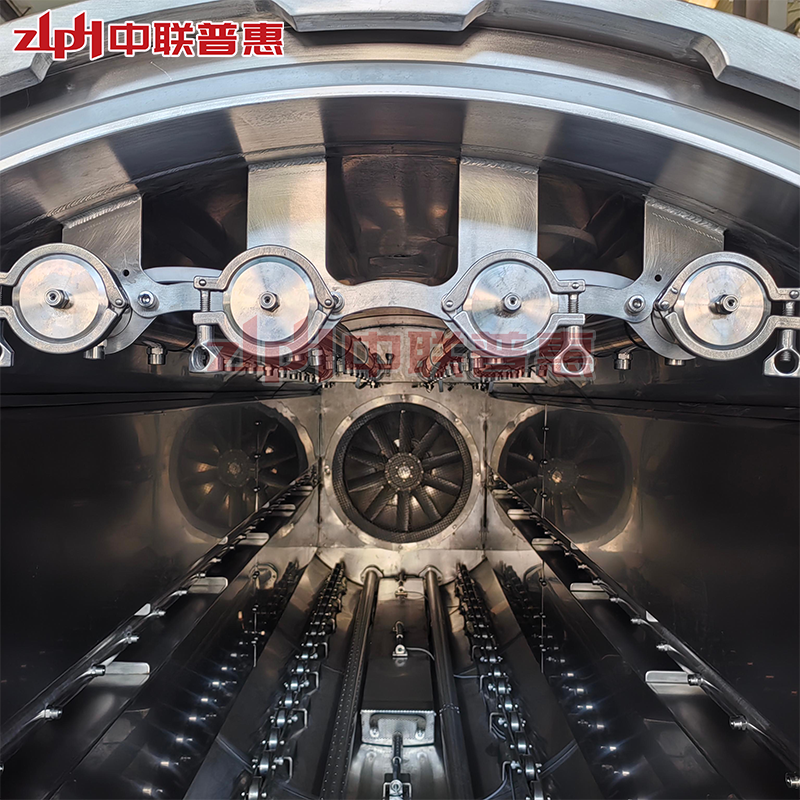

The ZLPH Steam-air Retort achieves efficient cooperative sterilization through the dynamic mixing of steam and air. Steam rapidly transfers heat to increase the temperature inside the can, and the uniform distribution of air ensures that the heat penetrates without blind spots. When processing tuna canned food, the retort can precisely control the temperature, pressure, and time, quickly raising the temperature inside the can to the ideal sterilization range. After being processed by the ZLPH Steam-air Retort, the microbial killing rate of tuna canned food is as high as over 99.99%, far exceeding the industry average, and building a solid safety barrier for consumers.

Precise Temperature Control for Preservation, Restoring the Deep-Sea Delicacy

Tuna has tender meat and is rich in high-quality protein and other nutrients. However, traditional sterilization methods often cause the meat to become tough, and the nutrients to be lost due to excessive heating, greatly reducing the flavor.

The ZLPH Steam-air Retort is equipped with an intelligent temperature control system, which can customize exclusive sterilization plans according to the characteristics of tuna meat and the formula of the canned food. By precisely adjusting the proportion and flow rate of steam and air, it achieves precise control of the sterilization temperature. While ensuring effective sterilization, it minimizes the damage to the meat quality and nutrients of tuna. The tuna canned food processed by this retort still has tender and firm meat. The retention rate of its rich nutrients is increased by 30%-40% compared with the traditional process, and the flavor restoration degree reaches over 90%, making consumers feel as if they are tasting the deep-sea delicacy.

High-Efficiency Production for Quality Improvement, Enhancing the Competitiveness of Enterprises

With the continuous growth of the market demand for tuna canned food, production enterprises are faced with the dual pressures of increasing production capacity and reducing costs. Traditional sterilization equipment often has problems such as long production cycles, high energy consumption, and small batch processing capacity, making it difficult to meet the rapidly changing market demand.

The ZLPH Steam-air Retort adopts a continuous and automated design, significantly improving production efficiency. Compared with traditional sterilization equipment, its hourly processing capacity is increased by 2-3 times, enabling the continuous production of tuna canned food. At the same time, the efficient energy utilization system reduces energy consumption and saves the operating costs of enterprises. In addition, the compact structural design of the retort saves production space, facilitating enterprises to optimize their production layout, respond more flexibly to market demands, and comprehensively enhance their market competitiveness.

Stable Quality Output, Shaping the Brand Image

In the highly competitive canned food market, the stability of product quality is the key for enterprises to establish a brand image and win the trust of consumers. If the quality of different batches of tuna canned food is inconsistent, it will seriously affect the purchase experience of consumers and the reputation of the brand.

The ZLPH Steam-air Retort relies on standardized operation procedures and an automated control system to ensure that each sterilization process can be accurately replicated. Regardless of the origin of tuna raw materials and the fishing season, this retort can ensure that each batch of products reaches a unified high-quality standard. The stable quality output helps enterprises stand out in the market, gradually establish a good brand image, attract more consumers, and lay a solid foundation for the long-term development of enterprises.

In the booming development of the tuna canned food industry, the ZLPH Steam-air Retort, with its significant advantages such as efficient cooperative sterilization, precise temperature control for preservation, high-efficiency production for quality improvement, and stable quality output, has become the core equipment for promoting the quality upgrade of the industry. With the continuous innovation and improvement of technology, the ZLPH Steam-air Retort will continuously empower tuna canned food production enterprises, bring more safe, delicious, and high-quality products to consumers, and lead the industry to a higher stage of development.

If you're interested in learning more about our ZLPH Retort or exploring potential cooperation opportunities, feel free to reach out to us via email at saleshayley@zlphretort.com or connect with us on WhatsApp at +86 15315263754.