How Does a Rotary Retort Autoclave Ensure Even Heat Distribution and Prevent Localized Overheating of Product Trays?

In modern food processing and sterilization, consistent heat distribution is essential to ensure food safety, product quality, and shelf stability. The ZLPH rotary retort autoclave is a highly advanced sterilization solution designed to achieve this goal. Unlike static systems, which rely on convection alone, a rotary retort machine uses controlled rotation, precise temperature management, and optimized steam circulation to prevent localized overheating and guarantee uniform sterilization across all product trays.

1. The Principle of Rotary Movement

One of the most important features of a rotary retort autoclave is its rotation mechanism. During the sterilization process, product trays or containers are continuously rotated. This movement ensures that every part of the product is exposed to the same level of high-temperature steam or hot water. The constant motion prevents layering of dense products, such as sauces or soups, and eliminates temperature variations between the top and bottom of the trays. By promoting dynamic heat transfer, the retort machine maintains uniform temperature distribution inside every package.

2. Advanced Heat Circulation System

The rotary retort machine is equipped with a high-efficiency circulation system that distributes heat evenly throughout the chamber. Whether the heating medium is steam, hot water spray, or water immersion, the circulation fans or pumps ensure continuous movement of the fluid. This helps eliminate “cold zones” and prevents hotspots that could cause localized overheating of product trays. The result is consistent sterilization throughout the batch — a crucial factor in food safety compliance.

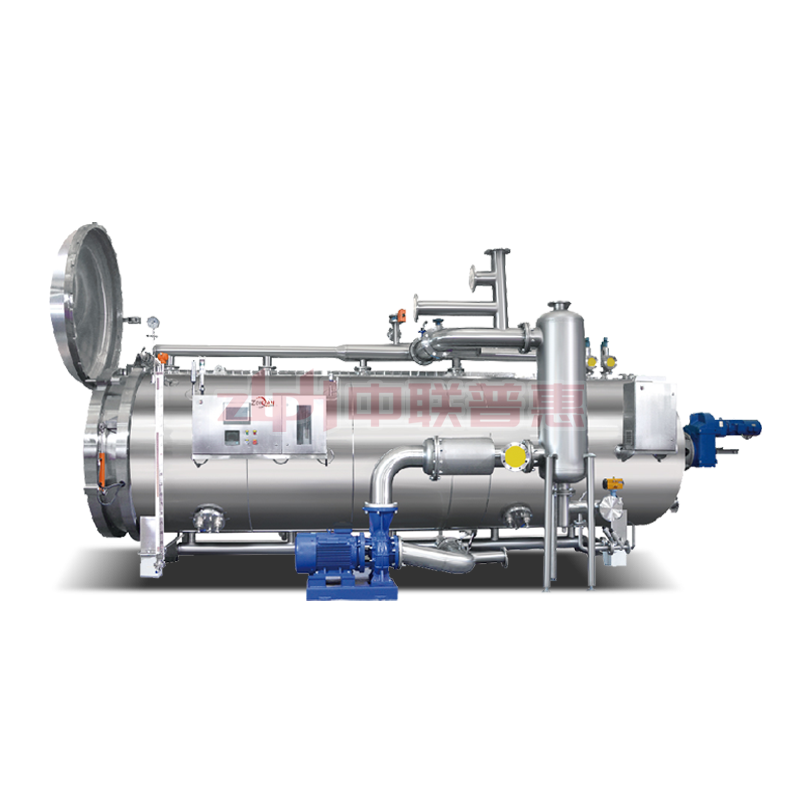

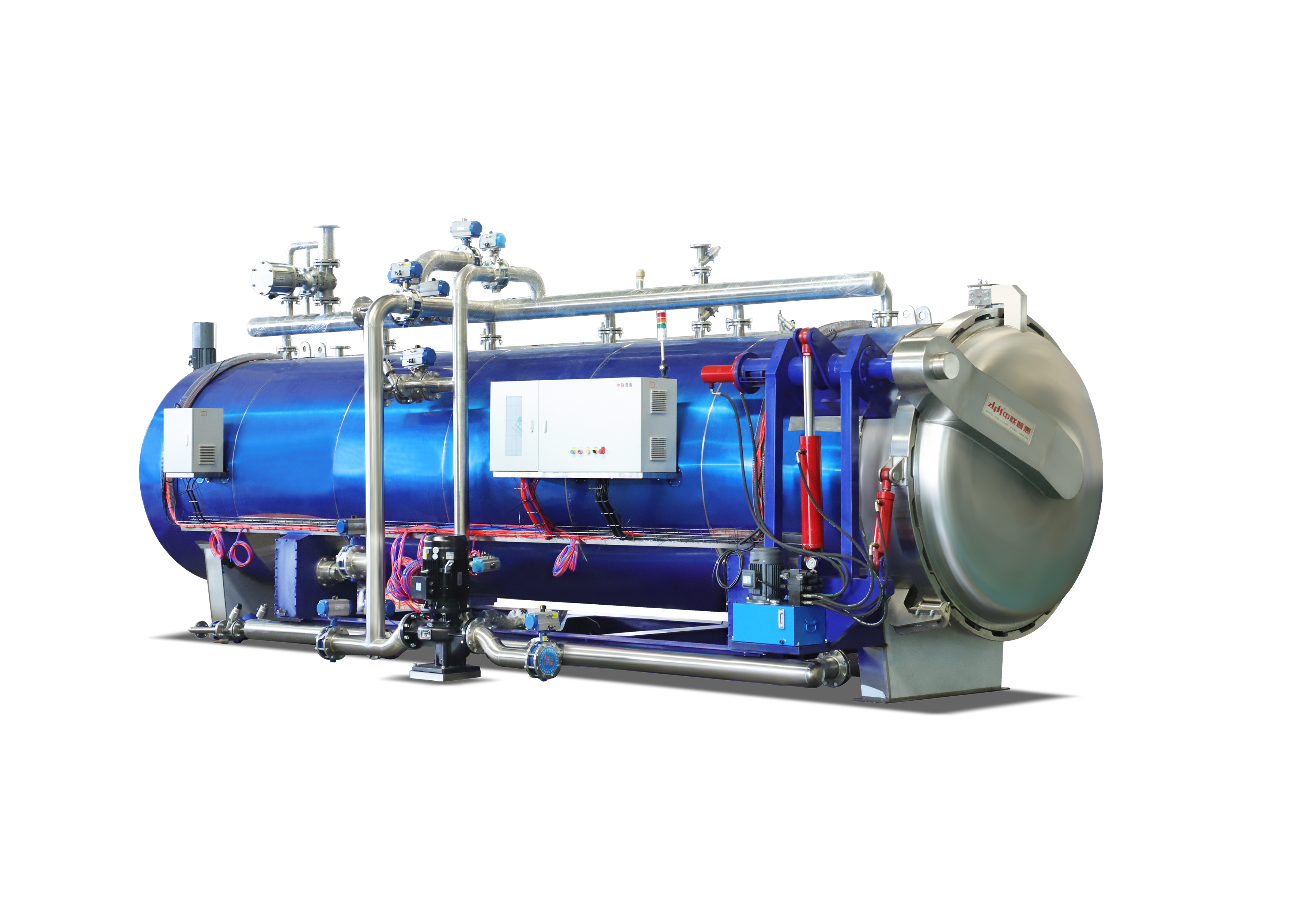

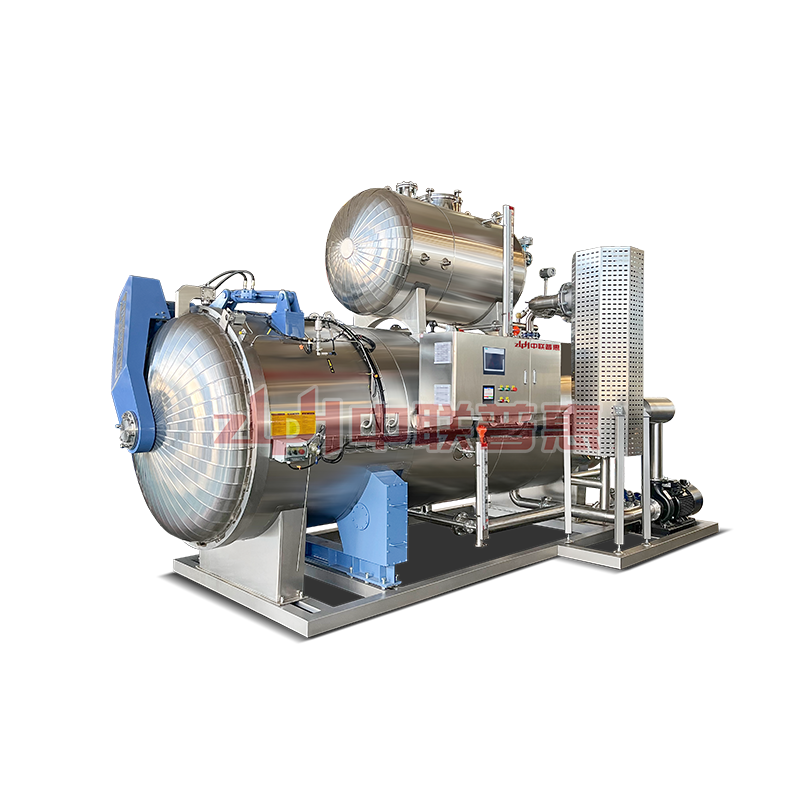

retort machine

retort autoclave

rotary retort autoclave

3. Precision Temperature and Pressure Control

The ZLPH sterilization retort machines incorporate intelligent control systems that continuously monitor temperature and pressure in real time. Sensors are strategically placed inside the autoclave to detect any deviation in temperature. If irregularities occur, the system automatically adjusts heating intensity and rotation speed. This fine-tuned control guarantees that the rotary retort autoclave maintains stable internal conditions, reducing the risk of overcooked edges or under-sterilized centers.

4. Balanced Steam and Condensate Management

Another important design element in a retort autoclave is its steam management system. Excess condensate can cause uneven heating if not properly drained. The rotary system’s continuous motion ensures condensate does not accumulate under trays, allowing steam to flow freely around every product. This guarantees a consistent high-temperature steam environment and prevents overheating in localized areas.

5. Enhanced Product Protection

The gentle rotation of a rotary retort machine not only promotes even heat transfer but also protects delicate packaging materials, such as pouches or plastic cups, from direct exposure to extreme heat. The rotation reduces temperature gradients within each container, preserving product texture, color, and nutritional value. This makes the system ideal for viscous or sensitive foods like sauces, soups, or bird’s nest beverages.

A rotary retort autoclave ensures even heat distribution through its advanced rotation mechanism, precision control system, and efficient steam management. Compared to static systems, the sterilization retort machine delivers superior consistency, product safety, and energy efficiency. Whether used for canned foods, beverages, or ready-to-eat meals, the retort autoclave and its rotary design set a new benchmark for uniform, reliable, and high-quality sterilization in modern food processing.

rotary retort machine

sterilization retort machine

retort machine

ZLPH has been breaking the barriers of food technology for a long time. Through our unparalleled persistence and high standards of product quality, we have provided high-level, advanced technology and reliable solutions to all our industry partners, which has also indirectly consolidated This reinforces our position as a leader in the food machinery industry and a trustworthy supplier.