What Types of Packaging Can a Rotary Retort Autoclave Handle?

In modern food processing, maintaining both safety and quality during sterilization is critical. The ZLPH rotary retort autoclave has become a preferred choice for manufacturers looking to achieve precise sterilization, especially for viscous or delicate food products. One of its key advantages lies in its versatile packaging compatibility. Whether it’s ready-to-drink beverages, sauces, soups, or instant bird’s nest, the rotary retort autoclave can accommodate a wide range of packaging materials while ensuring consistent sterilization through the rotary retort process.

1

Glass Bottles

Glass bottles are a popular choice for premium beverages, soups, and bird’s nest products. The ZLPH rotary autoclave ensures that heat is evenly distributed throughout the bottle, avoiding “cold spots” that could cause under-sterilization. During the rotary retort sterilization process, gentle rotation prevents sedimentation and maintains the appearance of transparent products. The structure of glass bottles also resists deformation at high temperature, making them ideal for repeated exposure to high-temperature steam.

2

Metal Cans

Metal cans remain one of the most common packaging types for canned foods and drinks.The ZLPH rotary retort machine applies uniform pressure and temperature, preventing distortion and ensuring every part of the can receives equal heat treatment. The rotational movement inside the rotary retort autoclave helps improve heat transfer efficiency, reducing sterilization time while preserving taste and texture.

3

Aluminum or Retort Pouches

Flexible pouches, such as aluminum or multilayer plastic retort pouches, have become increasingly popular due to their lightweight and cost-effective nature. The rotary autoclave allows these pouches to move continuously during sterilization, avoiding the risk of overcooking or uneven heat distribution. The rotary retort machine also maintains the pouch’s integrity by carefully balancing internal and external pressure, preventing bursting or wrinkling.

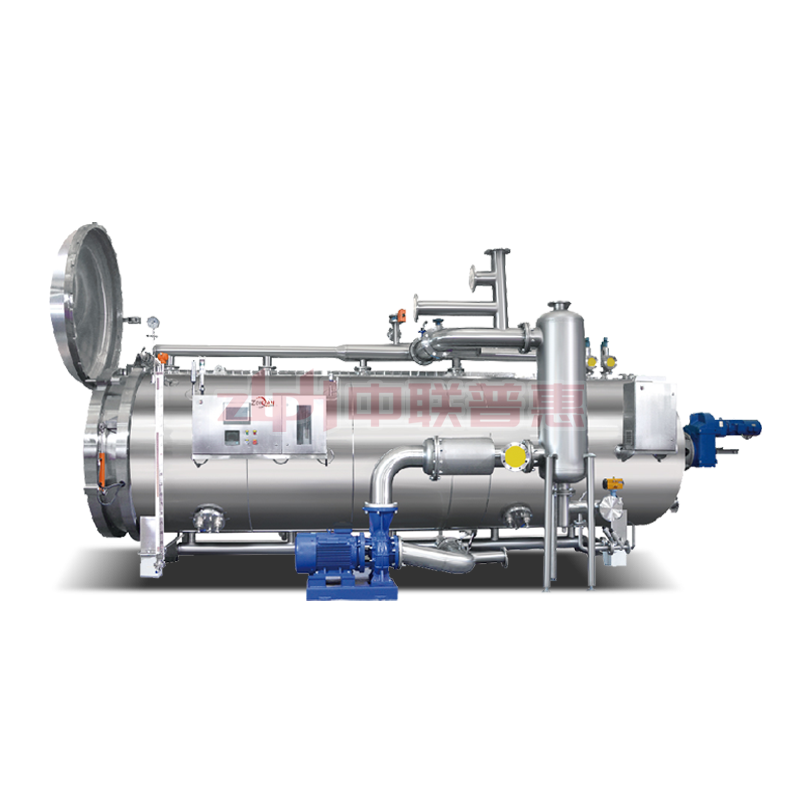

rotary retort sterilization

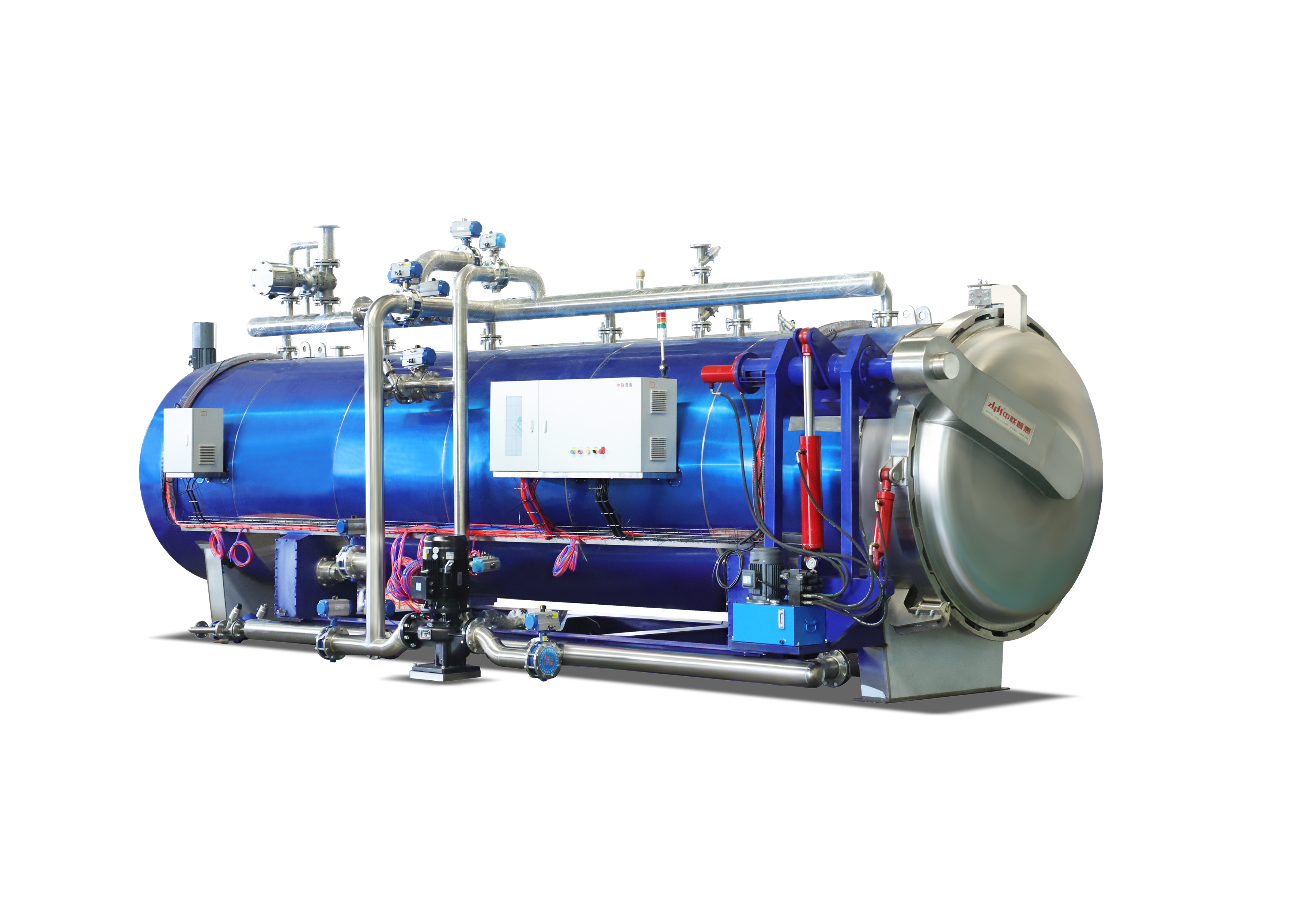

rotary retort machine

rotary retort autoclave

4

Plastic Containers

For ready-to-eat foods and beverages, plastic containers like PP (polypropylene) and HDPE (high-density polyethylene) are frequently used. The rotary retort machine can handle these materials effectively by combining pressure control and rotational movement, ensuring the packaging maintains its shape without warping. During rotary retort sterilization, precise temperature management allows for safe sterilization without damaging the product or container.

5

Glass Jars

Similar to bottles, glass jars are commonly used for desserts, soups, or nutritious products like instant bird’s nest. The rotary retort autoclave gently rotates the jars to ensure even sterilization and maintain the natural consistency of the food inside. The rotary motion also minimizes product layering, resulting in a visually appealing final product.

Why Packaging Compatibility Matters

Choosing the right packaging material directly impacts product safety, appearance, and shelf life. The rotary autoclave stands out because it can handle diverse packaging types—rigid, semi-rigid, or flexible—without compromising product integrity. The ZLPH rotary retort machine is particularly beneficial for high-viscosity foods that require consistent heating, ensuring that every portion is thoroughly sterilized.

The ZLPH rotary retort autoclave is a versatile and efficient solution for sterilizing food products in various packaging types. From glass bottles and metal cans to retort pouches and plastic containers, its rotational design ensures uniform heat distribution, safe sterilization, and product consistency. Whether you are producing premium beverages or ready-to-eat meals, the rotary retort sterilization ensures the highest quality standards are met while preserving the flavor, texture, and nutritional value of every product.