Analysis of the Sterilization Process of Retorts

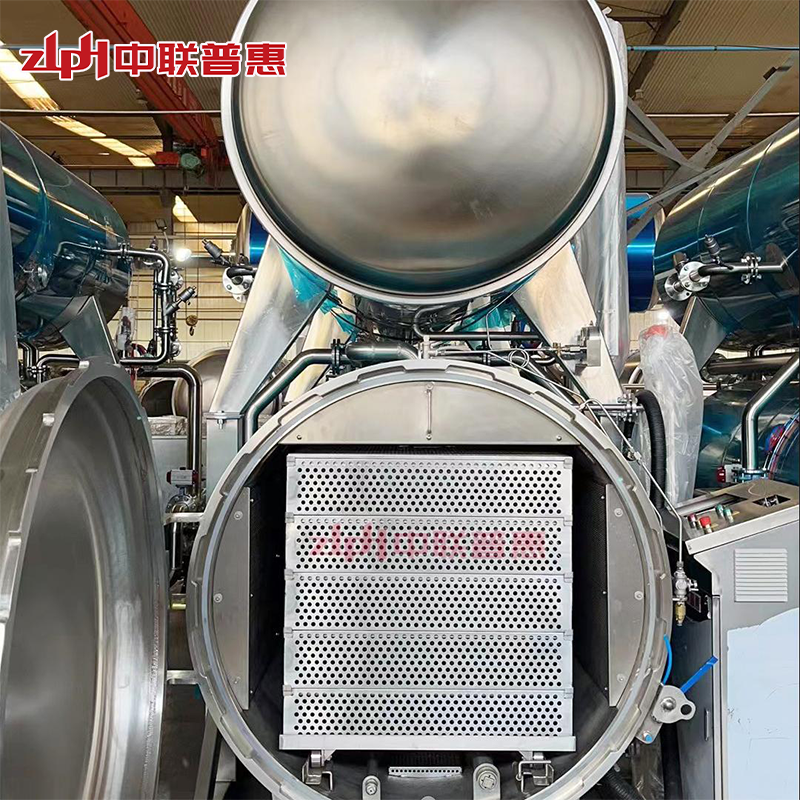

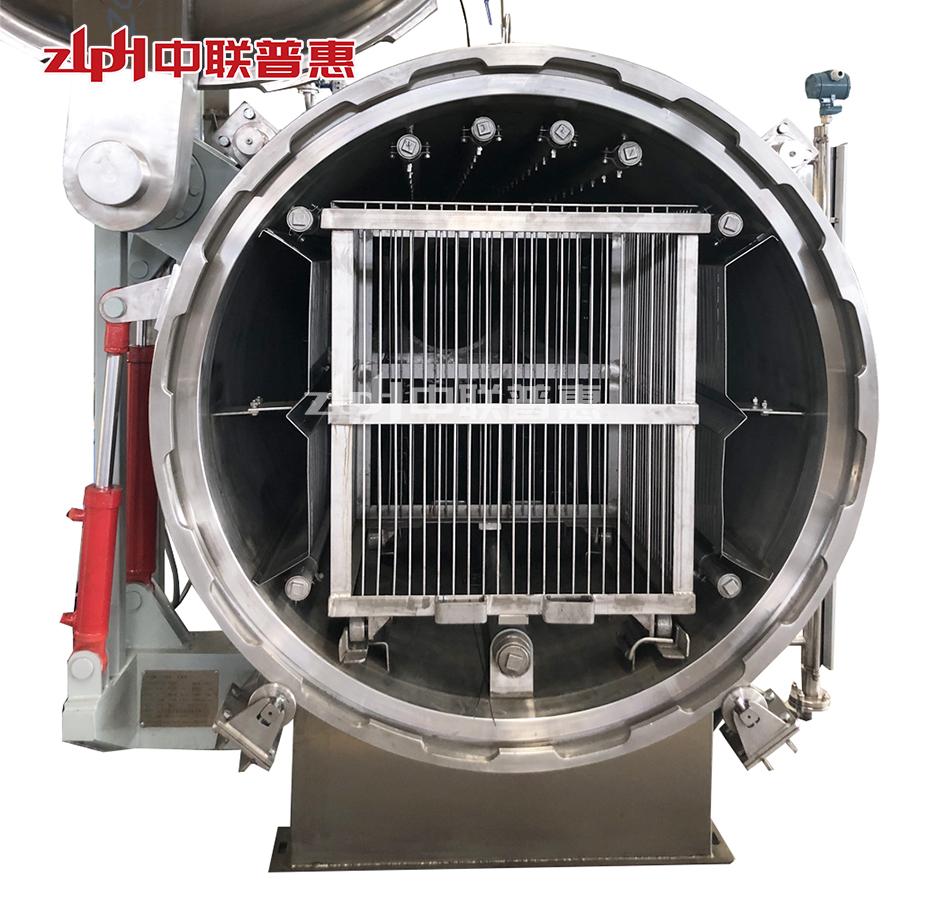

Retorts, also known as sterilization pans or sterilizers, are the core equipment in the food industry for the high - temperature sterilization of packaged foods. Their sterilization process involves multiple key parameters and steps. The following is a detailed analysis of this sterilization process.

I. Sterilization Principle

Retorts create a high - temperature and high - pressure environment to break down the protein structure of microbial cells, causing them to denature and coagulate, thus losing their biological activity and achieving the goal of sterilization. The specific process is as follows:

Heating Stage: After loading the food to be sterilized into a special container, it is placed in the retort and sealed. Heating is carried out through steam or other heat sources, causing the pressure in the retort to gradually rise, and the temperature also rises accordingly.

Insulation Stage: Once the pre - determined sterilization temperature is reached, maintain a constant temperature and pressure for a certain period to ensure that microorganisms are completely killed.

Cooling Stage: After sterilization, cooling is carried out through the cooling system to prevent the food from deteriorating due to over - heating.

II. Sterilization Methods

According to different heat transfer methods, the sterilization methods of retorts can be divided into the following categories:

1. Hot Water Circulation Sterilization

Principle: The food is completely immersed in hot water, and the hot water circulates in the retort to achieve uniform heating.

Characteristics: The heat distribution is uniform, and it is suitable for various packaging forms of food.

2. Water Spraying Sterilization

Principle: Hot water is sprayed onto the surface of the food through nozzles or spray pipes to achieve comprehensive, rapid, and stable heating.

Characteristics: The temperature is uniform without dead corners, and the heating and cooling speeds are fast, especially suitable for soft - packaged foods.

3. Steam Sterilization

Principle: Steam is directly introduced to raise the temperature, and the latent heat of steam is used for sterilization.

Characteristics: The heating speed is fast, but the heat distribution may be uneven, and there are cold spots.

4. Steam - Air Mixing Sterilization

Principle: This method combines steam sterilization and air - assisted heating. Compressed air can be injected into the retort, and a unique turbine fan rotates to break up cold air masses, forcing the mixture of steam and air to circulate in the retort.

Characteristics: There is no need for steam to discharge cold air. There are no absolute cold spots, and the heat distribution during the sterilization stage is controlled within ±0.5°C. The ventilation turbine fan forces the steam - air mixture from one end of the retort to the other, covering all products perfectly and avoiding problems of ventilation system instability, saving more than about 15% of steam.

III. Process Parameter Control

The sterilization effect of retorts is affected by multiple process parameters, mainly including the following aspects:

1. Temperature

The sterilization temperature is a key factor affecting the microbial lethality rate and needs to be accurately controlled according to the type of food and packaging form.

Generally above 121°C, with differences for different foods.

2. Pressure

Pressure affects the saturation temperature of steam and the heat transfer efficiency of food.

A constant pressure needs to be maintained to ensure uniform temperature.

3. Time

The sterilization time needs to be determined according to factors such as the heat penetration of food and the degree of microbial contamination.

Too short a time may lead to incomplete sterilization, and too long a time may damage the quality of food.

4. Control Method

The control methods of retorts are divided into manual, electrical semi - automatic, computer semi - automatic, and computer full - automatic control.

The computer full - automatic control type can accurately store the sterilization process, and the temperature control accuracy can reach ±0.1°C, ensuring the standardization and unity of the sterilization effect.

IV. Application in Food Sterilization

Retorts are widely used in the food industry, such as for the sterilization of canned foods, soft - packaged foods, and snack foods. Different food types and packaging forms require different sterilization methods and process parameters. For example:

Canned Foods: Steam sterilization or hot water circulation sterilization is often used to ensure uniform heating of the food in the can and avoid can swelling.

Soft - Packaged Foods: Water spraying sterilization is mostly used. Uniform heating is achieved through nozzles or spray pipes to prevent bag breakage.

Snack Foods: The sterilization method is selected according to the characteristics of the food and the packaging form to ensure the nutrition and flavor of the food.

V. Selection and Maintenance of Retorts

1. Selection

Select a suitable retort model and sterilization method according to the production scale, food type, and packaging form.

Consider factors such as the control method of the equipment, temperature control accuracy, and safety performance.

2. Maintenance

Regularly check the key components of the retort, such as its tightness, pressure gauge, and safety valve.

Clean the sewage and dirt in the retort to keep the equipment clean and dry.

Follow the operating procedures to avoid equipment failures or safety accidents caused by incorrect operations.

The sterilization process of retorts is an important link in ensuring food safety. By accurately controlling process parameters such as temperature, pressure, and time, and combining different sterilization methods, microorganisms in food can be effectively killed, the shelf life of food can be extended, and the health of consumers can be ensured.