What Exactly is an Instant Bird’s Nest Rotary Retort Autoclave and How Does it Differ From a Standard Autoclave?

In modern food processing, ensuring both nutrition preservation and product safety has become increasingly important. For delicate and valuable products like instant bird’s nest, traditional sterilization equipment often cannot meet the precision and consistency required. This is where the retort autoclave—especially the rotary type designed for bird’s nest production—plays a vital role. A retort autoclave is a type of advanced sterilization retort machine that uses high temperature steam and pressure to kill bacteria, extend shelf life, and maintain food quality. But how exactly does an Instant Bird’s Nest Rotary Retort Autoclave work, and what makes it different from a standard retort machine?

Understanding the Retort Autoclave

A retort autoclave is a sealed pressure vessel that sterilizes packaged foods using high temperature steam or hot water circulation. The process ensures that harmful microorganisms are destroyed while retaining flavor, texture, and nutrients. This type of food retort machine is widely used in canned foods, ready-to-eat meals, soups, and beverages.

For bird’s nest products, however, the requirements are much stricter. Bird’s nest has a gelatinous texture and delicate structure that can easily degrade under uneven heat. That’s why manufacturers prefer a rotary retort autoclave—a more advanced sterilization retort machine with a rotating basket system that ensures uniform heat penetration.

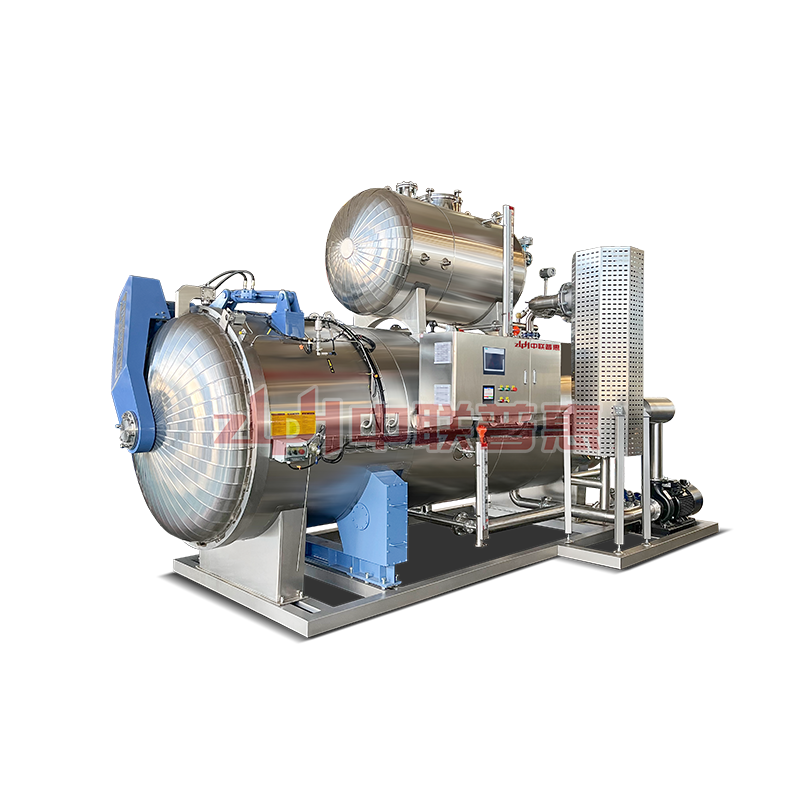

food retort machine

food retort machine

What Makes the Rotary Retort Autoclave Unique

Unlike a conventional retort machine, the rotary design of this retort autoclave allows continuous rotation during the sterilization process. The rotation gently agitates the contents inside the container, distributing heat evenly and preventing layering or clumping. This feature is essential for products with viscous or semi-liquid content—such as instant bird’s nest beverages or concentrated soups.

Additionally, the rotary retort autoclave ensures more consistent sterilization by minimizing temperature gradients. When combined with precise control of high temperature steam and pressure, this system prevents overcooking at the edges while ensuring the core of the product reaches the required sterilization level.

The Role of High Temperature Steam in Food Sterilization

The use of high temperature steam is fundamental in the operation of a sterilization retort machine. Steam penetrates packaging rapidly, transferring heat efficiently to the product. In a food retort machine, this ensures quick and uniform temperature rise, critical for maintaining the nutritional and sensory properties of foods like bird’s nest.

For example, most instant bird’s nest products are sterilized between 115°C to 121°C for a precisely calculated time. The retort autoclave automatically adjusts the steam and cooling cycles to maintain ideal conditions, ensuring safety without compromising quality.

Key Differences from a Standard Retort Machine

The Instant Bird’s Nest Rotary Retort Autoclave differs from a standard retort machine in several ways:

Rotational Agitation:Regular retorts are static, but the rotary model continuously moves containers to ensure uniform heating.

Product Adaptability :The rotary food retort machine is ideal for high-value, heat-sensitive products like bird’s nest, soups, sauces, and baby food.

Improved Heat Distribution:The combination of rotation and high temperature steam minimizes sterilization time while ensuring consistency.

Automation and Control:Advanced sensors and PLC systems in the sterilization retort machine monitor temperature, pressure, and rotation speed for precision control.

The Instant Bird’s Nest Rotary Retort Autoclave represents a new generation of food retort machines built for efficiency, precision, and quality preservation. By combining rotational movement, high temperature steam, and smart controls, it delivers superior sterilization performance compared to conventional systems. Whether for bird’s nest, soup, or other ready-to-eat foods, this advanced retort autoclave ensures safety, consistency, and premium product quality—making it a cornerstone of modern food processing.

sterilization retort machine

sterilization retort machine

food retort machine