What Training or Operating Procedures are Required for Using a Rotary Autoclave?

In modern food manufacturing, the rotary autoclave plays a vital role in ensuring product safety, extended shelf life, and consistent quality. However, to achieve reliable sterilization results, operators must undergo proper training and follow strict operational procedures. Handling a rotary sterilizer requires a clear understanding of temperature control, rotation speed, pressure balance, and safety protocols. Inadequate training or improper handling can lead to under-processed or over-sterilized batches, compromising both product quality and operational safety. This article outlines the essential training topics and standard procedures for operating a rotary retort machine efficiently and safely.

1. Understanding Rotary Autoclave Principles

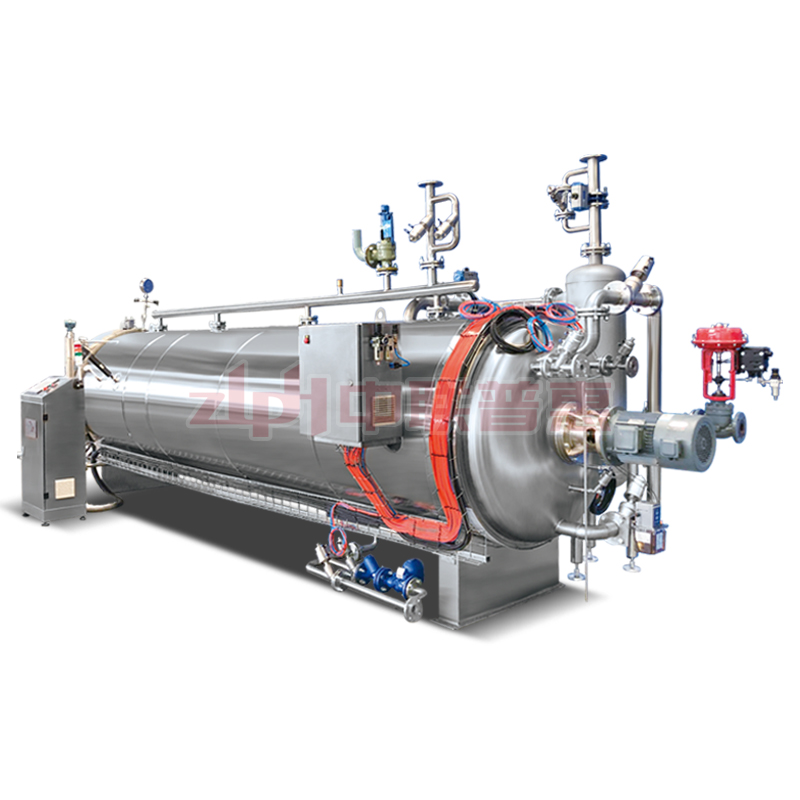

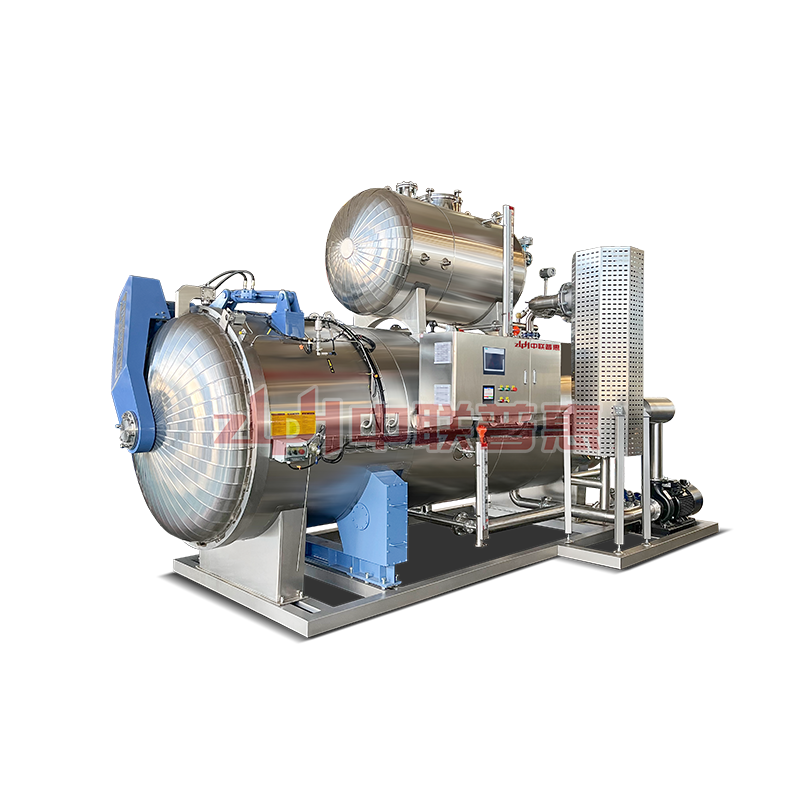

Before operating a rotary autoclave, every technician must understand the basic working principle. Unlike static systems, a rotary sterilizer rotates the product baskets during processing to ensure uniform heat penetration. The combination of rotation and pressurized steam or water evenly distributes heat throughout the packaged food, eliminating cold spots and ensuring consistent sterilization.

Operators must understand how parameters such as rotation speed, pressure, and time interact. Proper knowledge of how the rotary retort autoclave achieves sterilization helps in adjusting the settings based on the type of packaging—cans, pouches, or bottles—to prevent deformation or damage.

2. Operator Training and Certification Requirements

Personnel responsible for running the rotary retort machine should receive structured training provided by the manufacturer or a certified technical trainer. The training should cover equipment structure, control systems, emergency shutdown procedures, and batch documentation.

Certified operators learn to identify abnormal pressure fluctuations, detect unusual noises from the autoclave retort sterilizer, and respond appropriately to prevent equipment failure. Continuous skill updates and refresher courses help ensure that staff can adapt to new models and software versions of the rotary sterilizer with advanced digital controls.

rotary autoclave

rotary sterilizer

rotary retort machine

3. Pre-operation Checks and Preparation

Before starting a sterilization cycle, operators must conduct detailed pre-operation checks. These include verifying the door seal integrity, ensuring the basket drive and rotating system function smoothly, and confirming that temperature and pressure gauges are calibrated.

Loading the rotary autoclave must follow strict guidelines—products should be evenly distributed to maintain balance during rotation. Overloading or uneven stacking can cause vibration, mechanical stress, and poor sterilization uniformity. The product type, packaging material, and batch weight determine the appropriate speed settings for the rotary retort autoclave.

4. Monitoring the Sterilization Cycle

During operation, the rotary retort machine automatically manages temperature and pressure through its control panel. However, operators must continuously monitor critical parameters throughout the cycle. Any deviation from set points could indicate a malfunction in heating, rotation, or pressure systems.

Modern autoclave retort sterilizers are equipped with data recording and alarm systems. Operators should review these logs to confirm that each batch meets sterilization standards. Consistent monitoring not only guarantees product safety but also provides valuable documentation for regulatory compliance and traceability.

5. Post-operation Procedures and Cleaning

After completing each batch, the rotary sterilizer should undergo a controlled cooling phase before unloading. Rapid pressure release or premature opening of the autoclave door can be dangerous and may damage the packaging. Operators must wait for internal pressure to stabilize and ensure that temperature levels are safe before removing baskets.

Cleaning the rotary retort autoclave is also an integral part of post-operation procedures. The inner chamber, rotating shafts, and basket drive should be rinsed and sanitized to prevent residue buildup. Regular cleaning extends equipment life and ensures hygiene compliance for future batches.

autoclave retort sterilizer

rotary retort autoclave

rotary autoclave

6. Safety and Maintenance Awareness

Operator safety must always be a priority. Training should emphasize proper use of protective gear, awareness of high-temperature hazards, and adherence to lockout-tagout (LOTO) procedures during maintenance.

Scheduled inspections of the rotary retort machine—including seals, bearings, and rotation mechanisms—help detect early wear and prevent unexpected breakdowns. Only qualified personnel should perform maintenance on the rotary retort autoclave to maintain warranty validity and ensure consistent sterilization performance.

Effective training and standardized operating procedures are the foundation of safe and efficient batch processing using a rotary autoclave. From pre-operation checks to post-cycle cleaning, every step impacts product safety, energy efficiency, and machine longevity. Training operators and ensuring they strictly adhere to correct operating procedures guarantees that every batch of products processed in a rotary autoclave meets the highest quality and food safety standards.

ZLPH has been breaking the barriers of food technology for a long time. Through our unparalleled persistence and high standards of product quality, we have provided high-level, advanced technology and reliable solutions to all our industry partners, which has also indirectly consolidated This reinforces our position as a leader in the food machinery industry and a trustworthy supplier.